Walk through a manufacturing plant where some type of oil or lubricant is commonly used as a thin film on parts, and you often find workers wearing two pair of gloves — a typical leather work glove or cut-resistant glove over top of a disposable glove you might use to wash dishes. They wear the disposable glove to keep their hands dry when the oil soaks through the outer glove. It’s a crude attempt to solve a serious problem, even if the workers themselves fail to realize just how serious the hazards may be.

These workers are trying to keep their hands dry and avoid contact with a potentially harmful chemical: oil. They may not realize the oil they encounter every day in the workplace is a chemical — in our experience, most workers do not — but they know it can make their skin dry, red, itchy or worse.

Irritations and allergies, which include contact dermatitis and eczemas, now represent more than 90 percent of occupational skin diseases. Not surprisingly, in 80 percent of those cases, the hands are affected. In 2014, there were 33,600 reported incidences of recordable occupational skin diseases. Some of those diseases may last 5-10 years, potentially forcing workers to change occupations. Oil, like most chemicals, can be absorbed through the skin into the bloodstream after prolonged contact and can cause health effects far more serious than common allergic reactions and irritation.

It all adds up to real costs — an estimated $1 billion for occupational skin diseases in the U.S. alone.

A growing impact

Even with the explosion of domestic oil production, regulations related to personal protective equipment (PPE) for use with oil-based products are limited. In the absence of regulations, workers typically default to (1) comfort and (2) performance when selecting and donning gloves. Protection is something of an afterthought, which is how we end up with makeshift solutions that ultimately can fall short across the board.

These can be difficult, demanding jobs, and the men and women tasked with them justifiably demand comfort and performance from their gloves. Workers must be able to wear the gloves for an extended period of time, but traditional cotton and leather gloves quickly become saturated with oil. In the absence of an appropriate barrier, traditional work gloves hold that oil against the skin throughout the day and lead to discomfort. That’s why so many workers try disposable gloves underneath, but the same lack of permeability that keeps oil away from the skin locks in heat and sweat, making for a hot, sweaty and uncomfortable solution. Double-gloving also can lead to hand fatigue and slipping, which can cause accidents. Eventually, workers take the gloves off, exposing their hands to harmful materials and risks such as cuts and abrasions, or creating impact or crush injury due to part slippage.

It doesn’t have to be this way.

Technology eliminates the need for compromise

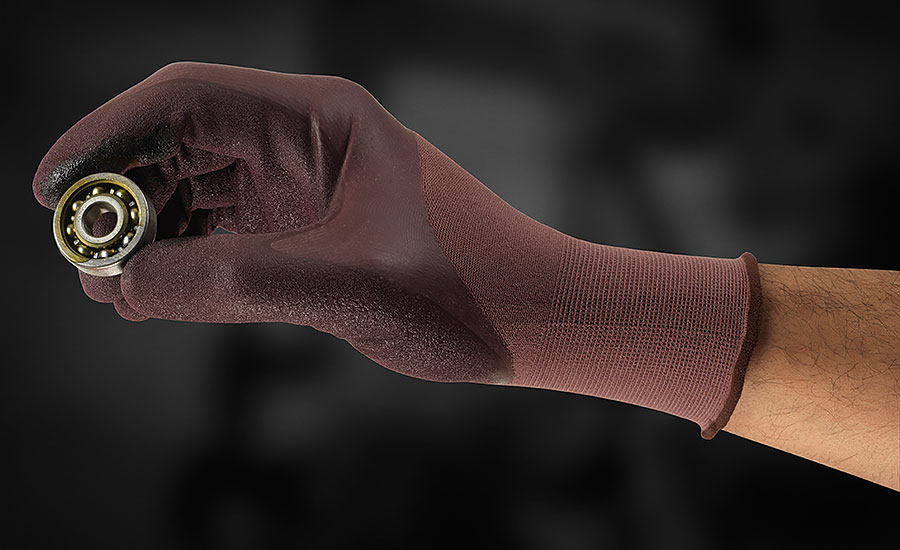

Today’s technologies deliver hand protection solutions that match the industry and application and provide the right balance of comfort, performance and chemical protection. It’s important to remember that different materials offer protection against different types of chemicals, including various oil-based compounds. There are gloves designed specifically to limit permeability in these environments while still providing superior grip, dexterity and comfort. There no longer is a reason to compromise.

Consider those drivers we discussed earlier — comfort and performance. Today’s technologies deliver on both counts while providing much-needed protection against exposure to oil. Consider:

- Comfort: New, liquid-impermeable, nitrile coatings can keep oil away from the skin while still enabling free movement of the hands and fingers and the dexterity needed to perform occupational tasks.

- Performance: New materials and contact patterns channel oil away from the surface of the glove to ensure a stronger grip to reduce hand fatigue.

Awareness is critical. Employers and workers today lack a clear understanding of just how dangerous prolonged exposure to oil can be, and that lack of awareness is illustrated in an insufficient approach to hand protection. It’s up to all of us in the PPE and occupational safety industries to better inform and equip organizations with the information and tools necessary to make their workplaces safe for all their employees.

For more information, visit www.ansell.com.

Footnote

i “Occupational skin diseases – a neglected occupational health problem” by Dr. Ivan D. Ivanov, Scientist Occupational Health, WHO.