Did you ever experience a synthetic fabric melting on your skin due to a fire?

It’s not fun. I had the experience once. Fortunately only my hand and wrist were burned, but I guarantee you, I don’t want to try it again.

Think about the risk, the danger of wearing something like this on the job when you’re doing hot work, for example, using a cutting torch or welding. Is there a fire hazard? Absolutely. For fire to occur three elements must come together forming the fire triangle: fuel, heat and oxygen. Your clothing provides the fuel, your cutting torch the heat and the air around you, the oxygen.

A second risk

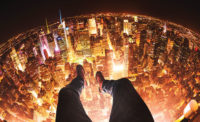

Let’s add another element of risk. You’re working at a height – on a tower, a pole, a roof, on a scaffold, a platform, a bridge. You’re an iron worker on the top as the structure goes up. Now we must add a fall protection plan to the mix. Anchorages, connectors and harnesses must be specified. Employers must establish and supervise programs for the education and training of employees in the recognition, avoidance and prevention of unsafe conditions. They must train each employee who might be exposed to fall hazards. In addition to assuring that each of these employees recognizes the hazards of falling, the employee must understand the procedures to be followed in order to minimize these hazards.

Procedures for inspecting and maintaining the fall protection equipment must be set up. Rescue provisions must be included in the plan. OSHA regs based largely on ANSI standards will provide more detail on the requirements. Of course some states can establish their own OSHA standards. When doing so, their regulations must be at least as stringent as the Federal standard. Several states have opted for their own programs.

Looking at the dual hazard we described earlier (fire and fall), let’s examine one state program, that of California:

Subchapter 4. Construction Safety Orders

Article 24. Fall Protection

§1670. Personal Fall Arrest Systems, Personal Fall Restraint Systems and Positioning Devices.

(a) Approved personal fall arrest, personal fall restraint or positioning systems shall be worn by those employees whose work exposes them to falling in excess of 7½ feet from the perimeter of a structure, unprotected sides and edges, leading edges, through shaft ways and openings, sloped roof surfaces steeper than 7:12, or other sloped surfaces steeper than 40 degrees not otherwise adequately protected under the provisions of these Orders.

Note: (1) Requirements relating to fall protection for employees working at elevated locations on poles, towers and other structures are provided in Section 2940.6(b) and (c) of the High Voltage Electrical Safety Orders.

(2) Requirements relating to fall protection for employees working on poles, towers, or similar structures are provided in Section 8615(g) of the Telecommunications Safety Orders.

(3) Requirements relating to fall protection for employees working in roofing operations are provided in Section 1730 of the Construction Safety Orders.

(b) Personal fall arrest systems and their use shall comply with the provisions set forth below. Effective January 1, 1998, except as permitted in subsections (c) and (d), body belts shall not be used as part of a personal fall arrest system.

(1) On suspended scaffolds or similar work platforms with horizontal lifelines which may become vertical lifelines, the devices used to connect to a horizontal lifeline shall be capable of locking in both directions on the lifeline.

(2) Horizontal lifelines shall be designed, installed, and used, under the supervision of a qualified person, as part of a complete personal fall arrest system, which maintains a safety factor of at least two.

(3) Lanyards and vertical lifelines shall have a minimum breaking strength of 5,000 pounds.

(4) Except as provided in Section 1670(b)(5), when vertical lifelines are used, each employee shall be attached to a separate lifeline.

(5) During the construction of elevator shafts, two employees may be attached to the same lifeline in the hoistway, provided both employees are working atop a false car that is equipped with guardrails; the strength of the lifeline is 10,000 pounds [5,000 pounds per employee attached]; and all other criteria specified in this section for lifelines have been met.

(6) Lifelines shall be protected against being cut or abraded.

(7) Self-retracting lifelines and lanyards which automatically limit free fall distance to 2 feet or less shall be capable of sustaining a minimum tensile load of 3,000 pounds applied to the device with the lifeline or lanyard in the fully extended position.

(8) Self-retracting lifelines and lanyards which do not limit free fall distance to 2 feet or less, ripstitch lanyards, and tearing and deforming lanyards shall be capable of sustaining a minimum tensile load of 5,000 pounds applied to the device with the lifeline or lanyard in the fully extended position.

(9) Ropes and straps (webbing) used in lanyards, lifelines, and strength components of body belts and body harnesses shall be made from synthetic fibers except for when they are used in conjunction with hot work where the lanyard may be exposed to damage from heat or flame.

Avoiding the burn

Paragraph 1670 covers much more; however, let’s address (9) above. Just about all standard webbing is made from synthetic fibers, the same synthetic fibers that melt and burn as described at the beginning of this article.

Because of (9) many companies that weld or use cutting torches have opted to switch to manufacturers using FR fabrics in the fabrication of their harnesses and lanyards in the State of California. Also, I would think in a few years Fed and other state OSHA programs will follow the same practice.

FR fabrics

Today several fire-resistant fibers are available. Their properties of strength and heat resistance make today’s high-performance fire-resistant fabrics a component to look for when choosing fall protection equipment for workers engaged in hot work at high places.