Typical flammable chemical storage considerations may include temperature, ignition control, ventilation, segregation and identification. Proper segregation is necessary to prevent incompatible materials from inadvertently coming into contact. If incompatible materials were to come into contact, fire, explosion, violent reactions or toxic gases could result.

Correct storage information can usually be obtained from the Safety Data Sheet (SDS), shipped container label or other chemical reference material. As required by OSHA’s hazard communication standard (29 CFR 1910.1200), an SDS must be on hand for every hazardous chemical in the workplace.

Chemical storage groups

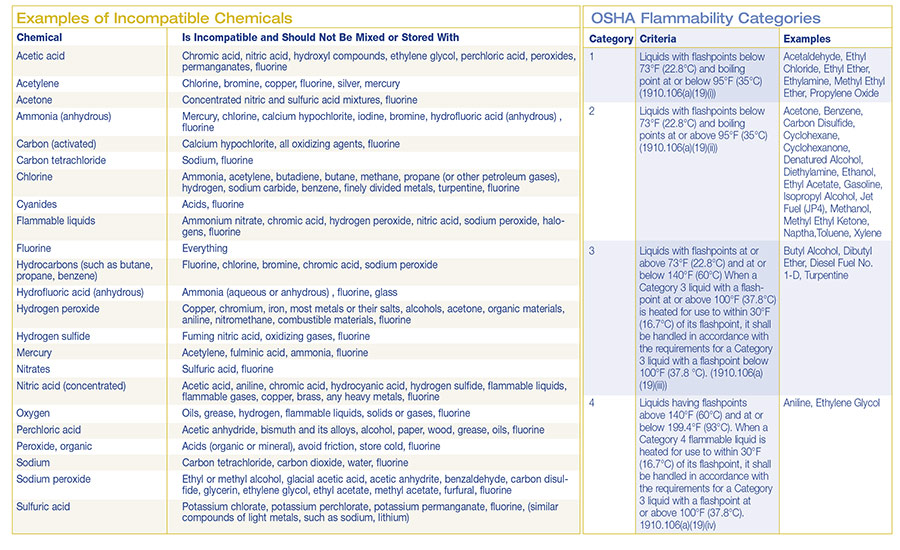

Chemicals are best segregated by hazard class to avoid incompatibilities. Never store chemicals alphabetically, except within a hazard class. Spill containment trays can be used to provide secondary containment and segregation on shelves. Some of the common incompatible chemicals are listed are listed on page 43.

Flammable liquids

To prevent fires, hazardous liquids require special precautions. Outdoor storage buildings, safety cans, and indoor storage cabinets help minimize risks. Always think covered and closed when storing, handling, or disposing of flammable liquids.

Mandatory OSHA regulations are based on NFPA Code 30 – Flammable and Combustible Liquids Code. In 1910.106 OSHA specifies safe handling practices for flammable liquids used in general industry.

Bonding and grounding

Bonding and grounding provide an electrically conductive pathway between a dispensing container, a receiving container and an earth ground. This eliminates the buildup of static electricity and allows it to safely dissipate into the ground. 1910.106(e)(6)(ii) states, "Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100°F (37.8°C), shall not be run/dispensed into containers unless the nozzle and container are electrically interconnected.” If the containers are not bonded and grounded, static spark could raise the vapor temperature above the flash point, causing an explosion.

A metal-to-metal connection must be maintained between the bonding and grounding cables and the containers. To accomplish this, remove all paint, dirt, rust, etc. from the area of connection.

Compressed gasses

Potential for simultaneous exposure to both mechanical and chemical hazards depends on the particular compressed gas. Gases may be flammable, explosive, corrosive, poisonous, inert or a combination of hazards.

OSHA requires employers to ensure cylinders are in a “safe condition.” Also , all compressed gas cylinders must be properly handled, stored and utilized. The contents of all compressed gas cylinders must be clearly identified. Gas cylinders should be properly secured at all times , and stored in a cool, dry, well-ventilated, fire-resistant area that meets all applicable regulations.

When a gas cylinder is empty or not being used the valve must be closed, the regulator removed and the valve protector cap secured in place. Always segregate flammable cylinders from cylinders that are considered oxidizers such as oxygen by a minimum of 20 feet or by a five-foot-high fire wall with fire rating of one-half-hour. Gas cylinders should be transported using hand trucks designed for that purpose.