During a near two-year period spanning mid-2013 to March 2015, OSHA conducted more than 7,000 inspections under 12 National Emphasis Programs (NEPs) addressing topics such as chemical processing, trenching, hexavalent chromium and combustible dust. However, inspections under one NEP accounted for 45 percent of the total, and more than 51 percent of the 16,000 violations issued. That NEP focuses on amputations from hazardous machinery, which are among the most severe workplace injuries and often result in permanent disability.

More recently, federal OSHA changed their rules to require employers to report amputations to the Agency. This has led—and will continue to lead—to increased enforcement and outreach. In fact, earlier this year OSHA created a hazard alert on food slicers in retail settings after receiving several amputation reports under the new reporting system.

What machinery causes amputations?

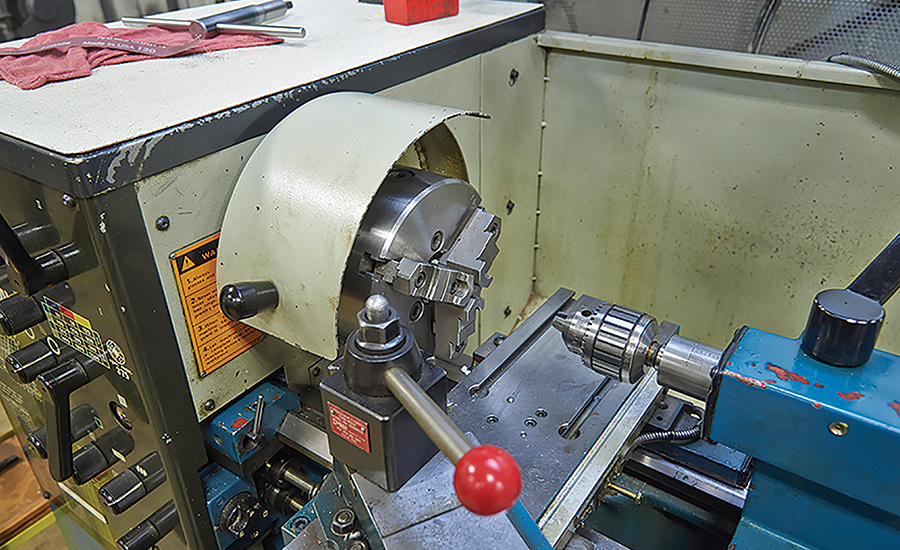

Amputations occur most often when workers operate unguarded or inadequately safeguarded mechanical power presses, power press brakes, powered and non-powered conveyors, printing presses, roll-forming and roll-bending machines, food slicers, meat grinders, meat-cutting band saws, drill presses and milling machines as well as shears, grinders and slitters.

These injuries also happen during materials handling activities and when using forklifts and doors as well as trash compactors and powered and non-powered hand tools.

Besides normal operation, the following activities involving stationary machines also expose workers to potential amputation hazards:

- Setup/threading/preparation for regular operation of the machine,

- Clearing jams or upset conditions,

- Making running adjustments while the machine is operating,

- leaning of the machine,

- Oiling or greasing of the machine or machine pans,

- Scheduled/unscheduled maintenance and

- Locking out or tagging out.

What can employers do?

Despite OSHA’s efforts, amputations still occur at a high rate. In 2013, there were more than 7,500 amputation cases requiring days away from work, according to BLS data. More than 40 percent involved 31 or more days away.

Employers should be able to recognize, identify, manage and control amputation hazards commonly found in the workplace such as those caused by mechanical components of machinery, the mechanical motion that occurs in or near these components, and the activities that workers perform during mechanical operation.

All mechanical motion is potentially hazardous. In addition to in-running nip points (“pinch points”)—which occur when two parts move together and at least one moves in a rotary or circular motion that gears, rollers, belt drives and pulleys generate—the following are the most common types:

• Rotating—circular movement of couplings, cams, clutches, flywheels, and spindles as well as shaft ends and rotating collars that may grip clothing or otherwise force a body part into a dangerous location.

• Reciprocating—back-and-forth or up-and d own action that may strike or entrap a worker between a moving part and a fixed object.

• Transversing—movement in a straight, continuous line that may strike or catch a worker in a pinch or shear point created between the moving part and a fixed object.

• Cutting—action generated during sawing, boring, drilling, milling, slicing, and slitting.

• Punching—motion resulting when a machine moves a slide (ram) to stamp or blank metal or other material.

• Shearing—movement of a powered slide or knife during metal trimming or shearing.

• Bending—action occurring when power is applied to a slide to draw or form metal or other materials.

Machine safeguarding with the following equipment is the best way to control amputations caused by stationary machinery:

• Guards provide physical barriers that prevent access to hazardous areas. They should be secure and strong, and workers should not be able to bypass, remove, or tamper with them. Guards should not obstruct the operator’s view or prevent employees from working.

• Devices help prevent contact with points of operation and may replace or supplement guards. Devices can interrupt the normal cycle of the machine when the operator’s hands are at the point of operation, prevent the operator from reaching into the point of operation, or withdraw the operator’s hands if they approach the point of operation when the machine cycles. They must allow safe lubrication and maintenance and not create hazards or interfere with normal machine operation. In addition, they should be secure, tamper-resistant, and durable.

Employers must safeguard machines and should consider this need when purchasing machinery. New machinery is usually available with safeguards installed by the manufacturer. Employers can also purchase appropriate safeguards separately or build them in-house.

Stay diligent

With OSHA now requiring employers to report all work-related amputations, there will be a heightened focus on amputations both under the NEP and in general. Enforcement aside, no employer wants employees to suffer an amputation; but it takes diligence to identify and maintain control of the hazards that cause them.