In the course of my travels and visits to a great many diverse business facilities over the last few years, I have come across very few situations where standing operators have not been provided with some sort of relief from the hard floors of their workplace. Not surprising given that soreness or pain are one of the top three reasons given for lost work days (National Safety Council stats 2014-15). It is widely accepted in industry, thankfully, that the provision of an anti-fatigue mat contributes to the operators’ wellness and productivity.

The subject of ergonomics has also raised awareness in the office environments, where personnel experience long periods of sitting in chairs. With the introduction of fully adjustable chairs, breakout areas and the sit/stand workstation, corporations, large and small, are investing in the wellness of their most valuable asset – their workforce. When you consider the cost to recruit, train and retain these persons, then it makes perfect sense to look after them rather than all the additional costs that are incurred to replace them, if they decided to look for a better employment or environment elsewhere.

Keep mats well maintained

I’d like to briefly point out the necessity of not only providing anti-fatigue mats, but maintaining them so that they achieve the results that they were purchased for. Most pieces of equipment have periodic inspections to keep them in good working order, but sadly, very few organizations check out that mat on the floor that operators can spend their entire working week standing on. This is the reason that we see the following:

- Broken and torn mats, creating trip hazards.

- Mats so old that they have long failed to provide any cushion, only some thin barrier between the concrete and the operator.

- Multiple mats stacked on top of each other – old worn out mats not disposed of but left in situ under the misunderstanding that they will provide extra anti-fatigue comfort.

- Mats with curled edges providing a potential trip hazard.

- Other material for standing on- wood platforms, even old pallets, cardboard or hard rubber pieces like cut up conveyor belts.

- Using the wrong type of mat for the application, i.e. using a regular dry environment anti-fatigue mat for a welding operator.

- Multiple mats become a hazard – if you need a long runner – get a one-piece mat – the right size.

- Mats being run over by forklifts. If anti-fatigue is needed in areas where there could be forklift traffic, there are solutions available for this.

- Mats with no provision to drain excess oil and coolants, making damaged or slick surfaces.

- Mats being destroyed by metal chips, chemicals and solvents – there are mats designed to prevent this – ask your supplier to test out a sample before you buy.

- Cut up pieces of disposable roll from matting being used as a fix-all solution and way past their useful life.

- Mats not staying in position, especially on very smooth or coated concrete floors. There are solutions available to fix this.

- Electrostatic discharge: anti-fatigue mats not ground wired correctly or not grounded at all.

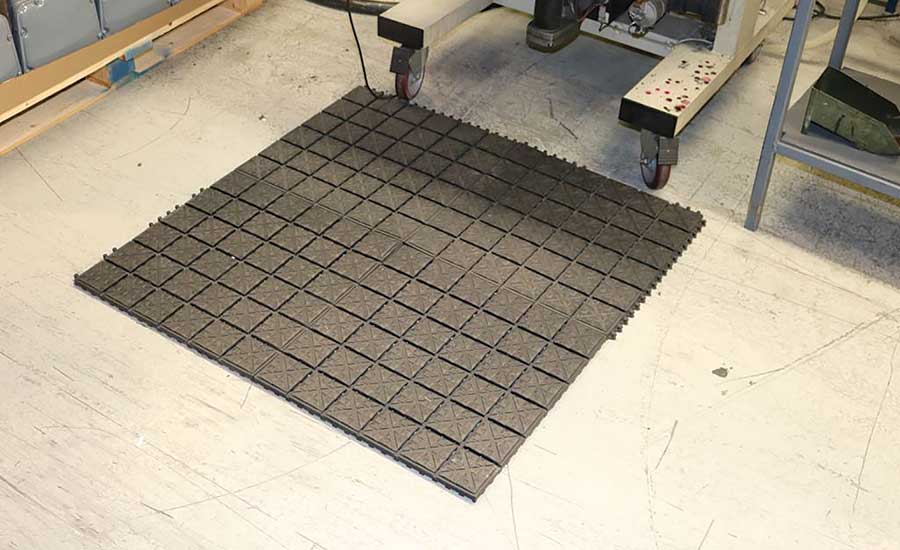

- No bevel edges on mats presenting a 90-degree edge for the unwary to trip on (see image).

So with a regular walk around, say every quarter, checking the condition of all your mats, these problem areas can be identified and quickly rectified. Remember the golden rule: Prevention is better than cure!

This routine check can be incorporated into 5S programs to ensure standards are met and that regular cleaning of the mats is carried out.

Do your research

If you are not sure which mats you should be using where, get advice from a reputable mat company. Many will sell you the mats that you “choose” to buy, but not many provide you with the necessary time or advice to ensure you get the right mat for the job.

Do not settle for making do with standard size mats when a particular size or shape is needed for the job. Ask for a custom one, as there are companies that will provide this. Yes, it will cost a little more, but potential trip hazards will be eliminated and the investment will provide greater value.

A good quality anti-fatigue mat is one of the best investments that you can make for a valued team member. Do not look at it as just another expense to pay for.

If I have raised more awareness to provide the right anti-fatigue mats and maintain them in good order, then my time writing this article will have been well spent.