Selecting and buying the appropriate safety gear is a critical part of making sure your teams go home safely to their families. It can be tempting to make the decisions based solely on the per-unit purchase price. But when it comes to keeping your people safe, reliability, durability, and usability should be priorities. You also need to consider the total cost of owning the equipment over the long run.

What can you do to meet your budget needs while also buying the best equipment possible? Simply put, you can look for ways to be leaner without compromising safety. For example, selecting gas detectors with features that allow you to have the smallest fleet possible can make a huge difference.

Consider this scenario

All 450 field employees at a company spend some portion of their time in an area known to have a high risk for exposure to H2S. It’s not a daily occurrence, but about once per week, they need an H2S detector. The employees also occasionally work in confined spaces. Between the H2S risk and the confined space entries, the safety manager estimates that each person would be safest if he wore a 4-gas instrument about 25 percent of his working hours.

Budgets are tight, so there isn’t a dedicated employee responsible for maintaining gas detectors. Instead, the safety manager does all of the trouble-shooting and repairs when he has time. He has other priorities, so it’s common that it will take weeks or even months for him to return an instrument to service.

The safety manager is also the one who is responsible for knowing who has which instrument. He keeps a spreadsheet with names and serial numbers, but it would be far too time-consuming for him to manually update that spreadsheet every day, so each employee is issued their own gas detector. If there is a problem, employees report it to their supervisors and arrangements are made to swap out the instrument. As a result, the safety manager isn’t sure that his spreadsheet is completely accurate.

Sometimes an instrument gets handed out while he isn’t in the office and he has to track it down when he gets a chance.

In this scenario, the company would likely purchase around 500 standard 4-gas detectors. Of those, 450 would be for each field employee and an additional 50 would be used to cover repairs and other downtime.

There are several opportunities for reducing the size of the instrument fleet and realizing cost savings in this scenario:

- Gas detection as a service – The need for spare instruments “just in case” can be virtually eliminated with a service program that provides replacement equipment any time the need arises. For example, it’s possible for a service provider to be alerted that an instrument has failed calibration. A replacement can be in hand within days. There’s no need to have several loaners available while the instruments go through a long trouble-shooting and repair process.

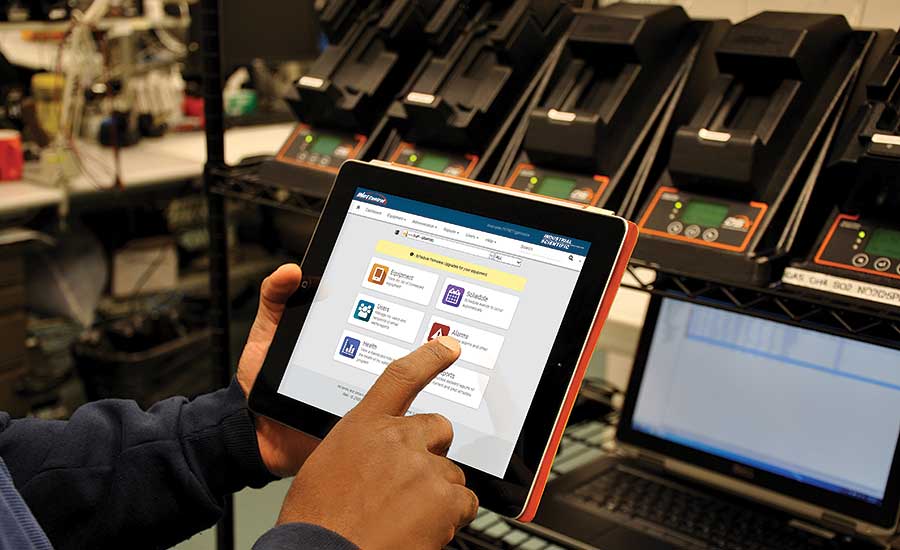

- Smarter maintenance management – The same software system that allows service providers to get an alert about a failed calibration can be used to monitor the health of equipment, enabling proactive maintenance. The software can be used to monitor when a sensor is nearing the end of its useful life and a replacement can be in hand before that first failed calibration. What’s more, the same software can be used to monitor whether or not equipment is being used properly. Are your gas detectors bump tested daily? If not, how do you know they will respond to toxic or combustible gases? Having an easy way to get a high level of understanding of how well your fleet is being maintained can go a long way in making sure every instrument is in good working condition at all times.

- Powerful user assignments – Gas detectors that allow users to be assigned on-the-fly can significantly shrink the size of the instrument fleet. For example, if users can quickly tap the gas detector to a tag that programs their name to the instrument, there’s no need for manual tracking. Electronic records can quickly show who has which instrument. With flexible and powerful user assignments, it becomes much easier to work with a pool of instruments rather than assigning one to each individual. You can greatly reduce the size a fleet by planning for how many people will need an instrument at one time instead of the total number of workers.

- Gas detectors built to last a lifetime – Gas detectors that are designed to withstand harsh environments can provide savings over the long-term. Less time is spent checking equipment, arranging for replacements, and managing repairs.

Saving time and money

Considering these four opportunities, it’s realistic for the company in the scenario above to significantly reduce the size of the instrument fleet. They don’t need as many spare instruments because replacement equipment automatically arrives within days of any problem that arises. More importantly, when the gas detectors are built to last, there is a less frequent need for significant maintenance.

Taking full advantage of these opportunities could easily bring the company down from 500 instruments to 100 instruments. The savings aren’t limited to the equipment costs, though. The safety manager is now spending far less time doing administrative work and keeping working instruments in the field. Instead, he is able to focus on identifying additional ways he can help to ensure employees go home to their families each night.