Of all the personal protective equipment workers use, safety footwear is probably worn more hours of the day than any other type of PPE. Once you slip on and lace up safety boots or shoes, you may wear them for eight, 12, 16 or more hours before taking them off. This is why having the right footwear for the job is critical to your safety and the prevention of injuries.

The human foot combines mechanical complexity and structural strength. The ankle serves as foundation, shock absorber and propulsion engine. The foot can sustain enormous pressure (several tons over the course of a one-mile run) and provides flexibility and resiliency.

The foot and ankle contain 26 bones (one-quarter of the bones in the human body); 33 joints; more than 100 muscles, tendons and ligaments; and a network of blood vessels, nerves, skin and soft tissue. These components work together to provide the body with support, balance and mobility. It is no wonder that a structural flaw or malfunction in any one part can result in the development of problems elsewhere in the body.

Protection from hazards

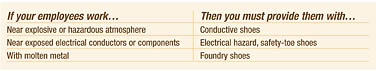

In the industrial workplace, feet need to be protected from a variety of hazards. OSHA regulations are fairly general regarding protective footwear. However, they adopt the ANSI Z41-1991 standards by reference, which include solutions for many common foot hazards.

Conductive Type I — grounds the wearer to help prevent ignition of explosive material.

Conductive Type II — worn by linemen working in Faraday Type Aerial lift equipment where induced voltage is a problem.

SD Type I and II — worn to protect workers from line electrical circuits; most often used in the electronic industry to prevent damage to electrical circuits.

Electrical hazard — provides protection against open circuits of 600 volts or less; the opposite of conductive footwear; no metal parts are in the sole or heel of the shoe but the protective toe may be steel or composite.

Puncture-resistant footwear — provides protection from sharp objects penetrating through the sole by use of a steel mid-sole.

Safety toe — steel or composite toe cap to protect against toe injuries from falling or rolling objects; has the following impact and compression standards

K C/75 — resists 50 pounds dropped from 18†or 75 foot pounds and 2,500 pounds of compression.

K C/50 — resists 50 pounds dropped from 12†or 50 foot pounds and 1,750 pounds of compression.

K C/30 — resists 50 pounds dropped from 7.25†or 30 foot pounds and 1,000 pounds of compression.

A good fit

Getting a proper fit the first time is important. Don’t expect footwear to shrink or stretch to your foot over time. Footwear should feel comfortable the day you buy it. This is especially important if safety toes are a requirement of your workplace since the toe box is fixed and will not move.Because the foot swells over the course of the day, the American Podiatric Medical Association recommends that shoes be tried on in the afternoon. It also suggests that workers try on both shoes. Many people have one foot larger than the other, so they should fit the shoe to their larger foot. You should be able to get at least the space of one finger in the back of the shoe to ensure room for the toes up front. You should also be able to move the toes freely and bend your foot without feeling the steel toe.

Footwear should be laced up properly, and you should walk around in the footwear on a hard surface to make sure there are no areas that are tight and rub against the foot.

For employees who work on their feet all day, shoe inserts can help improve foot function and minimize stress. Typically, most of our weight is placed on our heel and forefoot, but a shoe insert can distribute the weight so that the entire foot, from the heel up to the metatarsals, is bearing the forces generated by standing, walking and running. In addition, energy-absorbing materials in the insert act like a shock absorber to ease the stress.

The importance of… socks?

When sizing safety footwear, people often overlook the importance of socks. Socks that are too large may wad up inside the shoe, causing pressure and possible blisters. Socks that are too small may crowd the toes, limiting their motion within the shoe.Our feet produce about one cup of perspiration each day. Keeping your feet dry can be a challenge, but doing so helps lower the chance of getting athlete’s foot and reduces foot odor. Foot powders and sprays help, but the material from which your socks are made plays a major roll in keeping feet dryer and cleaner.

Cotton socks absorb nicely, but they retain about 60 percent of their moisture. Switching to wool socks helps wick moisture away from the foot, keeping your feet dryer. The wool fiber is actually a hollow tube, so even when wet it will retain its cushioning effect. Some people find wool too warm or irritating, so another excellent alternative is an acrylic blended sock. This also will help wick moisture away from your foot, but lacks the cushioning effect that a wool sock offers.

Proper care

Taking proper care of safety footwear will extend its life and help maintain a proper fit. Footwear should be inspected regularly for damaged stitching, dampness, cracks, wear on the soles and toes, and embedded metal that may impair electrical protection and expose feet to danger. Steel toes should not be exposed.

Footwear should be treated with a waterproof conditioner to soften and protect the leather. Mink oil is usually a good choice. Footwear should be allowed to completely dry inside and out between uses.

Make compliance easy

A comprehensive workplace hazard assessment and proper training can help keep foot-related injuries under control. The key is to make compliance easy for your workers by providing support in the selection process. One easy way to do this is to have a mobile boot truck come to your site. Another method is to have a purchase agreement with a credible local supplier of high-quality footwear.Either method can help you to ensure that employees are adequately protected from foot and toe injuries.