New standards pave the way for improved safety

Ten years later we haven’t made any progress. The number of OSHA citations for fall protection violations and their related fines are consistently among the top three and continue to increase from year to year. Fines for fall protection violations in 2008 reached as high as $877,000.

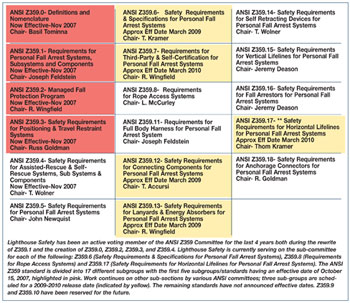

Hopefully this will change with the release of the new ANSI Z359.1 standards that took effect in November of 2007. This standard provides the guidelines and tools to develop a complete fall protection program and increase worker safety by mandating the introduction of new snap hooks and a new style of Y-lanyards. An entire family of new standards has evolved. This original family of standards is now available for under $400, through the American Society of Safety Engineers (ASSE) with membership. Visitwww.asse.orgfor more information.

Another family of standards dealing with horizontal lifelines; engineered systems; leading edge, self-retracting lifelines and more, is slated for completion in early 2009. This next family of standards will also help educate workers with regard to the dangers of “at-foot-level” anchorages and the equipment required for those exposures. Even though we now have stronger gates on our snap hooks, which help reduce burst-out, we can still have roll-out with an auto-locking carabiner.

Invest in new equipment and updated training

The probability of roll-out is greatly increased with an “at-foot-level” anchorage. A 12-foot free fall increases the forces on the body as well as on the connecting hardware. Only a few lanyards are rated for 12-foot free falls. A standard 6-foot lanyard, rated for a 6-foot fall, will blow out almost the entire shock-pak should a 6-foot fall occur. In a 12-foot fall, that lanyard may produce 2,000 to 3,000 lbs. of force on the body which is well above the OSHA limit of 1,800 lbs.

Many exposures can be reduced by using 12-foot free-fall lanyards, leading edge self-retracting lifelines, properly engineered and manufactured horizontal lifeline systems and newer anchorage devices. The cost to buy the correct equipment and provide the appropriate training for any given hazard may be 30-40 percent above standard equipment costs.

Many manufacturers now provide very specific, updated instructions on the proper use of their equipment, complete with illustrated “do’s and don’ts.” Unfortunately, these instructions are often lost or thrown away. Since they provide examples of proper installation and use, they should be treated like material safety data sheets (MSDS) and kept in a binder for easy worker access.

Keeping equipment information in an accessible place, raising expectations for worker safety, investing in new equipment and updated training, and carefully reviewing and following the new ANSI standards offer the best return for your safety dollar. These measures should go a long way toward providing a solid foundation for any successful fall-protection program

SIDEBAR: Facts about Roll-out and Burst-out

- Roll-out can occur when someone is using a non-locking snaphook.

- Roll-out occurs when someone is using a non-locking carabiner or an auto-locking carabiner. Triple locking or double action carabiners greatly reduce roll-out potential.

- The standards address the problem of roll-out. If someone has a locking snaphook, or carabiner, they may be meeting the standards.

- Burst-out is not addressed by the standards but is still a concern.

- Burst-out is a concern because the snaphook gates are only tested to 220 lbs. (350 side load) (ANSI Z359.1) (1992).

- The forces generated during a fall are much greater (at least 900 lbs.), and may cause failure of the gate if the load is applied to the gate.

- By choosing the correct geometry, we can reduce the possibility that any load will be applied to the gate.

- By using a carabiner with a capture pin, we can reduce the possibility that loading will be applied to the gate.

- By using a snaphook or carabiner with a compatible radius to its attachment point, we can reduce improper loading.

- By using a carabiner with a properly sized opening, when using with rope or cable thimbles, we can reduce roll-out/burst-out possibilities.

- Burst-out and roll-out have been greatly reduced by the new ANSI Z359.1 (2007). However, at foot level, anchorages still leave snaphooks and carabiners at risk when equipment is misused. A competent person should review compatibility of the snaphooks and carabiners as stated in the current OSHA and ANSI standards.