We had introduced a tower worker’s harness that met all the OSHA and ANSI requirements. Unfortunately, we were totally oblivious to the comfort level we were offering. Successfully passing drop tests, stress requirements and the like was not enough.

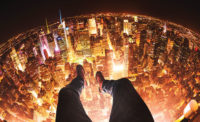

A young worker, in his early twenties, found the leg straps extremely uncomfortable. He had his own creative solution. With a little duct tape, he was able to get those straps “out of his way.” He fell, slipped out of the harness and plunged to his death. His widow and two small children took no comfort in the fact that he had been issued fully compliant fall protection equipment. As a manufacturer, we were not legally responsible, but we knew we had not provided all that was needed. We also realized this tragic scene had replayed itself multiple times across our industry.

Today, along with all reputable manufacturers of fall protection devices, we are in ongoing discussions with our end-users. We listen when they express a concern or a need. Then we take what we’ve heard to our engineers and product development team to make certain our equipment is user-friendly as well as OSHA compliant. Today webbing is soft and pliable, stretch fabrics are available. Hardware is lightweight; closure designs offer simple and quick operation.

Appearance and style have become extremely important in the safety equipment industry. Fabric and color influence a worker’s perception of a harness and his attitude toward wearing it. In short, if it looks good and fits comfortably, a worker will put it on. That’s step one. After proper training, he is ready for the job-site. Training includes equipment maintenance and inspection.

Inspection instructions

A fall protection system must be inspected regularly, meaning before each use. This is not just a cursory “onceover”. If it fails to pass inspection, immediately remove from service the faulty component or components. Follow these inspection instructions:

First, look for the equipment’s date of manufacture, indicated on the product label. Always check your manufacturer’s instructions. If the equipment meets the manufacturer’s instructions, begin to examine each component. Check for wear and deterioration. Look for evidence of impact loading. Visually inspect for loose threads, pulled rivets, burns, cuts, abrasions, or other evidence of chemical or physical deterioration that may have weakened the material or assembly.

Inspect all hardware including, but not limited to, hooks, buckles and D-rings. Look for any cracks or malfunction. Immediately remove from service all components that fail.

1. Stitching and webbing.

Check stitching for broken, burned, cut or pulled stitches. Broken strands of webbing appear as tufts on the webbing surface. To visually check for damage caused by corrosives, heat, chemicals and other conditions, hold the connecting device with your hands six to eight inches apart. Bend the webbing in an inverted “U” to cause surface tension and expose problem areas. Inspect the entire length. For deceleration units, check the stitching for broken, burned, cut or pulled stitches. Check the breakaway jacket for cuts, broken stitches, tears, stretch marks or other evidence of impact load.

2. Broken strands

Inspect rope lanyards for broken strands by twisting the rope slightly to undo the braiding. Inspect the entire lanyard in this manner. Discard lanyards with broken strands.

NOTE: Twisted rope, such as nylon filament and polyplus rope used in lanyards, is subject to a condition known as “hockling,” similar to the condition often seen in a telephone handset cord. Causes may be a repetitive twisting movement such as normal hand rotation in hooking and unhooking, a lanyard dangling freely, or using the lanyard to suspend equipment. Preventive measures include: 1) Inspection and smoothing out after each use, 2) Storing neatly, and 3) Never using a lanyard for towing or hoisting. Some hockling is normal and is not a reason to discard a lanyard.

3. Inspect all hooks, D-rings and all other metal parts.

Check hardware for sharp edges and cracks. Rollers must not be distorted and should roll freely. Check all parts, especially corners and attachment points, for wear and cracks.

4. Destroy and replace all worn or damaged equipment.

Never use it! Using this equipment may cause injury or death.

5. Remember, the inspector is the most important part of any inspection procedure.

He or she must be well trained and understand what he/she is looking for. Our objective is not merely compliance. We must do our part to provide a safe work environment.