A few decades ago, there was no national standard governing hi-viz apparel. Prior to 1999, people working in “low light” daytime conditions or at night were subject primarily to regulations drawn at the state level. Compliance with 50 different sets of regs led to both dangerous situations and high costs. Consistent national standards give workers and employers alike a firm foundation. They also establish a baseline for hi-viz garment manufacturers.

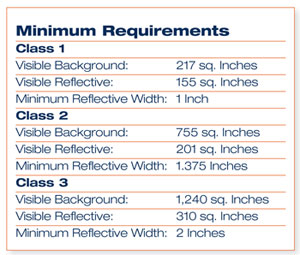

The standard applies to working conditions 24 hours a day. To meet the safety needs of different work environments, apparel is divided into three classes, with each class requiring a minimum amount of fluorescent background along with a minimum level of retroreflective material (see chart).

Class 1 apparel is to be used in environments where workers are adequately separated from conflicting streams of traffic, where they possess ample conspicuity to non-complex environment backgrounds and where vehicle and work equipment speeds are 24 mph or less. Applications falling within these guidelines include warehouse and parking lot attendants, sidewalk maintenance workers and delivery truck drivers.

Class 2 apparel applies to vicinities where vehicle speeds are in the 25-49 mph range and in environments that require increased visibility. Work conditions may include inclement weather, the presence of complex environment backgrounds and activities that require workers to be in close proximity to vehicle traffic or may distract them from conflicting traffic. Depending on specific conditions, roadway construction workers, utility workers, survey crews, railroad workers, school crossing guards, airport baggage handlers, law enforcement personnel, accident site personnel, emergency response personnel, high volume parking and toll gate personnel may all wear Class 2 apparel.

Class 3 apparel is required in areas where vehicle speeds are in excess of 50 mph. Workers exposed to these speeds include emergency services personnel, survey crews and road construction crews. It also applies to any workers required to be conspicuous throughout their entire range of motion for at least 1,280 feet, be identifiable as a person and be required to perform multiple tasks that could distract them from conflicting traffic.

Lots of options

Work wear suppliers are taking steps to help employers comply with the high-visibility standard. They’ve launched high-visibility lines with items rated according to the apparel classes identified in the standard. As determined by the specifications, the fabric will not shrink or fade. Breathable materials protect from the sun, release soil, dry quickly and resist bacteria and odor.

Many options allow compliance with the standard while also meeting workers’ needs. Just about all features available in traditional winter wear, for example, can be found in high-viz styles, such as bomber jackets or parkas, zip in-out fleece liners and attached or separate hoods. The same can be said for lighter weight windbreakers and rainwear, along with “hoodies” and T-shirts. All of this apparel meets ANSI Class 3 or Class 2 requirements.

The 2010 ANSI standard also describes Class E garments. Shorts or pants complying with Class E requirements must have a minimum of 465 square inches of fluorescent background, along with 108 square inches of retroreflective material. They are made to be worn with a Class 2 garment, thus creating a Class 3 ensemble.

Even hi-viz head wear is available. Under the Class E provision, high-viz head wear has a minimum background of 78 square inches with 10 square inches of reflective material.

Comfort and security

Work apparel is not only a matter of safety; it must allow workers to move easily and perform required tasks, as well as protect them from the elements. Factors such as temperature, exposure time, wind, humidity, gender, age and body metabolism affect a worker’s comfort level. Shirts and pants also need to withstand tough work conditions. Fabric choice is important. In warm seasons and climates, a 65 percent polyester/35 percent cotton blend is durable, absorbent and cool — and will hold up to multiple washings. In cold weather, layering enables workers to start their day bundled up for warmth and then remove layers as the temperature rises and activity warms the workers.

Effective layering is based on a simple principle: keep warmth in and moisture out. Thanks to today’s breathable and wicking fabrics, comfort is more attainable than ever.

Security is also a primary consideration. Uniforms, vests, hats and footwear help identify who does or does not belong on a work site. Contractors often place their logos on apparel to easily identify their workers.

What about vests?

The most familiar hi-viz garment is the vest, which comes in lime green or orange with reflective stripe. Vests are manufactured as Class 1, 2 or 3 apparel.

Beyond basic design specs, users can select other product features. What type of closure do you prefer or need? Hook and loop, zipper or snaps? If a zipper, do you need a non-conductive material?

Do you want pockets? Where? How many? What style? Consider what will be placed in the pockets.

How about a breakaway feature? Additional hook-and-loop closures allow the vest to be ripped off if caught in machinery or traffic.

Finally, color and fabric! Lime green or orange? Both meet the standard. Mesh or solid? Mesh is cooler — an important factor if working in high heat and humidity.