The search for new energy sources including shale gas, fracking, offshore drilling, land-based drilling and remote drilling requires faster, more easily deployable 24/7 safety/risk mitigation solutions that real-time gas detection and VOC monitoring provides.

The search for new energy sources including shale gas, fracking, offshore drilling, land-based drilling and remote drilling requires faster, more easily deployable 24/7 safety/risk mitigation solutions that real-time gas detection and VOC monitoring provides.

Industrial accidents, such as the 2010 catastrophic explosion of the Deepwater Horizon oil rig, continue to emphasize the need for effective gas detection and monitoring solutions. Organizations such as the U.S. Occupational Safety and Health Administration (OSHA) also continue to set standards and define the acceptable level of toxic gas exposure to personnel.

The cost of ignoring potential public environmental asset and worker safety is a high risk to major global energy companies. No longer can organizations allow an accident to become an incident. As a result, the need to comply with regulations and legislation, protect assets, mitigate risk, and ensure worker safety now requires organizations to deploy innovative, high-performance yet competitively priced gas detection solutions via an advanced system approach.

The New Requirement: Real-Time Wireless Gas, Leak and VOC Detection

The new method of wireless, 24/7 detection combines securely accessible sensors and instrumentation with wireless communication and provides risk mitigation for energy exploration and refining operations via real-time, 24/7, accessible-anywhere VOC, toxic chemical, location-based monitoring, analysis and assessment. The resulting benefits are cost-effective safety of energy exploration and refining operations, workers and the public.

Now, more than ever, facility managers and safety officers at exploration facilities and refineries know that implementing a reliable, end-to-end toxic gas detection system is of paramount importance to ensure the safety of workers and surrounding communities, protect assets and mitigate risks and comply with industry and government regulations.

Traditional, fixed-wired systems are often used in these applications, but there are several drawbacks, including cost of installation, deployment time (cabling and trenching), maintenance and difficulty of service, to name a few. In addition, remote alarm notifications may not be visible or loud enough to alert workers to potential hazards over a wide area.

MeshGuard: Connected, Intelligent Wireless Gas Detection System

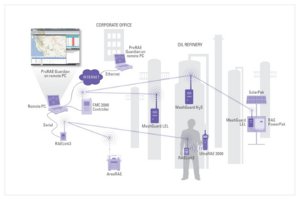

To solve these issues, RAE Systems’ MeshGuard Wireless Gas Detection System with RAEPoint is a battery operated, rapidly deployable hazardous area monitoring system combines advanced gas-detection technology with the latest in wirelessly connected data systems. MeshGuard with RAEPoint is new, and completely unique to industry, and allows safety officers to elevate worker safety in hazardous environments by extending the range of alarm notifications and enabling remote relay functionality across a wireless mesh network.

MeshGuard with RAEPoint communicates with wireless detectors and controllers and can use any of its five internal relays to trigger audible and visible alarms to provide additional alert notification in noisy environments. MeshGuard not only saves lives, but tens of thousands of dollars in regulation compliance and information processing. MeshGuard’s rugged design delivers reliable performance in harsh and potentially hazardous industrial environments, such as oil refineries, oil and gas exploration, oil and gas production, plant maintenance turnarounds, tank farms and facility fenceline monitoring. MeshGuard can improve worker safety and save significant time and expense typically incurred when running signal cabling in hazardous environments. By detecting and recording a wide range of deadly gases and quickly relaying the data to an easy-to-understand central system, safety personnel have up-to-date information from throughout the network of sensors at a finger’s touch.

The ProRAE Guardian (PRG) Wireless Safety System represents an advanced generation of remote 24/7 real-time wireless threat-detection solutions. The PRG System serves as a secure, Internet-based command center for monitoring toxic gases, Volatile Organic Compounds (VOC) and radiation threats. It allows safety officers to receive instantaneous, real-time threat data combined with the physiological status and location of workers to facilitate faster, better decision making.

About RAE Systems Inc.

RAE Systems solutions provide the wireless, 24/7 monitors and software infrastructure for the new energy-driven economy, and deliver efficiency and continued innovation to the complex process of worker and asset safety and risk mitigation. RAE Systems innovates, designs and manufacturers gas sensors and radiation detectors. The company offers a full line of fixed and portable gas detection solutions, including handheld and personal chemical, compound and radiation detection instruments. RAE Systems’ real-time safety and detection systems have been deployed by organizations in the oil and gas, fire and hazmat, industrial safety, national security and environmental markets, helping save lives and maintain safety in 120 countries. The company’s industry-leading gas sensors and radiation detection solutions are widely recognized for their performance and reliability. Learn more at raesystems.com.