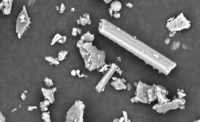

Crystalline silica, A.K.A frac sand, is used as part of the mix is injected into wells for hydrocarbon recovery. Frac sand acts as a proppant, or means of holding open fracture drock to allow access to oil and natural gas for extraction. Thousands of pounds of sand are transported to well sites, then conveyed and blended with fracking fluids before high-pressure injection; all of these processes can expose well site workers to respirable silica dust.

Silica exposure & silicosis risk

Workers exposed to high levels of respirable crystalline silica may be at risk for silicosis, an occupational lung disease. Symptoms may take years to develop and include inflamed lungs, severe shortness of breath, cough, fever and weight loss. Scarring lesions reduce the lung’s oxygen intake ability, and can result in susceptibility to tuberculosis, chronic bronchitis and even death. Silicosis has no cure.

In 2012, NIOSH released field study findings concerning worker overexposure to airborne silica during hydraulic fracturing operations. Air samples were collected at 11 North American hydraulic fracturing sites with the following results of 116 samples collected:*

- 47% showed silica exposures greater than the calculated OSHA PEL.

- 79% showed silica exposures greater than the NIOSH REL of 0.05 milligrams per cubic meter (mg/m3).

- 9% of all samples showed silica exposures 10 or more times the PEL, with one sample more than 25 times the PEL.

- 31% of all samples showed silica exposures 10 or more times the REL, with one sample more than 100 times the REL.

Regulatory action & recommendations

NIOSH reported their findings to hydraulic fracturing operators, along with recommendations as to site evaluation and control of crystalline silica exposure. Those measures included dust reduction through capping unused sand mover fill ports, freshwater application around well sites and limiting time spent in dusty areas. Other recommended practices include enclosure of dust release areas and use of installed dust collection and ventilation systems.

OSHA has established a Permissible Exposure Limit (PEL) stating maximum worker exposure to crystalline silica during an eight-hour work shift (29 CFR1926.55, 1910.1000), as well as the National Emphasis Program (NEP) for Crystalline Silica exposure intended to “identify, reduce, and eliminate health hazards associated with occupational exposures.” **

Respiratory protection

If silica dust exposure levels have been determined to be a workplace hazard at a given site, OSHA 29 CFR 1910.134 Respiratory Protection Standard requires that employers provide correct, NIOSH-approved respirators as well as respirator fit testing, training and medical evaluations. Basic respirator guidelines include use of an N95 NIOSH-certified respirator for crystalline silica airborne exposures at concentrations less than or equal to 0.5milligrams per cubic meter of air (mg/m3) **.

Silica levels exceeding 0.5 mg/m3 require use of a full-facepiece respirator that provides protection for up to 2.5 milligrams per cubic meter of air (mg/m3). For additional protection and comfort, a PAPR equipped with high-efficiency filters and tight fitting facepiece may also be used within concentrations of up to 2.5 mg/m3. When working within environments with concentrations of up to 25 mg/m3, a supplied-air respirator in pressure-demand or positive-pressure mode may be used. A Type CE supplied-air respirator is also appropriate for abrasive blasting applications. Lastly, any environment where concentration is unknown or is above 25mg/m3, a self-contained breathing apparatus (SCBA) is required. ****

Workers are advised to take protective measures such as showering and changing clothes before leaving work sites, and keeping informed as to health screening opportunities. Eating and drinking should be avoided within dusty work areas; cigarette smoking exacerbates lung damage that is due to silica dust overexposure. ***

For the latest silica-related information, view the NIOSH Pocket Guide to Chemical Hazards at www.cdc.gov/niosh/npg/ and visit www.silica-safe.org.

Resources

* OSHA NIOSH Hazard Alert DTSEM 6/2012 Worker Exposure to Silica during Hydraulic Fracturing

** NIOSH Respiratory Protection Recommendations for Airborne Exposures to Crystalline Silica

*** OSHA, Crystalline Silica Exposure Health Hazard Information

**** NIOSH Pocket Guide to Chemical Hazards