1 You can’t transform a Class II (Combustible Dust) Hazardous location into an Unclassified Location

According to NFPA 499: Recommended Practice for the Classification of Combustible Dust and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas, companies must keep dust levels continuously below 1/8 inch, or you have a Class II Hazardous location. I think we can all agree that 1/8 inch is basically a zero-tolerance stance since it’s roughly the size of two stacked nickels.

Given this strict level, transforming a Class II Hazardous location into an Unclassified location sounds like Mission Impossible. But it is possible. The principle by which this can happen is stated in Annex A. 6.3.2 of NFPA 499: “…good housekeeping can determine the difference between …a classification of Div.2 and unclassified.” Later in Section 6.5.1 it states that “it is usually not necessary to classify the following locations where excellent housekeeping prevents the following: (a) Visual dust cloud (b) Layer accumulations that make surface colors indiscernible.”

|

| Chart 1 |

What type of ‘excellent housekeeping’ can prevent the clouds and accumulations? One engineered approach works by robotically directing high velocity and high mass airflow to create an overhead barrier. This barrier controls dust like an air curtain, keeping overhead structures clean from combustible dust. NFPA 499 makes allowances for this type of technology in 6.8.3: “In addition, walls, partitions, enclosures or other barriers and strong air currents will also affect the distance that dust particles will travel and the extent of the Division 1 and Division 2 locations.”

Consider the money-saving implications. Darrell Cloudt, president of ESoT (Energy Solutions of Texas), has experience with electric installations across a wide spectrum of industries. He reports that, on average, the cost for a Class II Div 1 installation increases by a factor of 10! So if electrical work normally costs $10/sq.ft. for a typical manufacturing plant, the cost for a Class II Hazardous location in that plant will increase to $100/sq.ft. Business logic dictates that a proactive solution that costs less is preferable to this expense.

2 All combustible dust is created equal.

Because dust is a function of the substance processed, combustible dust varies significantly. Specifically, dust has a wide spectrum of variances including:

- Density

- Size

- Moisture content

- Shape – i.e. is the dust round or ragged?

- Adhesive characteristics – i.e. does the dust adhere easily to surfaces or not?

- Static charge

These factors vary considerably from industry to industry, and even from plant to plant. You have to know what you’re dealing with to design a realistic solution to the type of dust you are generating. For the overhead barrier, this means the velocity required to keep the dust from settling can vary by a factor of 3.

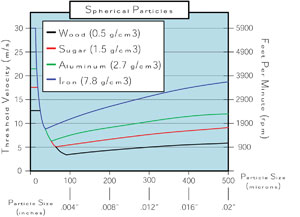

You would think that the larger the dust, the harder it is to eliminate. Part of that answer is true. But it doesn’t follow that smaller dust is easier to control. Take a look at Chart 1 (on p.50) from The Fire Protection Research Foundation’s Towards Estimating Entrainment Fraction For Dust Layers (Authored by Erdem A. Ural). This shows the different velocity levels required to move four types of dust particles.

3 Manual housekeeping is the only way to keep a plant clean from overhead dust.

Joists, ducts, purlins, lights and the like have to be cleaned. Even surfaces that theoretically ‘shouldn’t’ collect fugitive dust, like false ceilings, are equally dangerous.

Historically, overhead dust has been managed by periodically putting employees up on scissor lifts or ladders to clean places that can’t be reached otherwise. The problem with this approach is that you are trying to remediate an unsafe environment with an unsafe solution.

There is an engineered approach that prevents dust from accumulating and prevents employees from mounting one of those scissor lifts. With this approach, a robotic clean fan creates an air barrier in the overhead spaces by high velocity and high mass directed airflow. The velocity needed is contingent on the properties of the dust generated, so it will vary accordingly. This approach is a one-time investment that can keep a plant in continual OSHA compliance without risking employee safety.

4 You can capture 100% of fugitive dust.

Filtration systems definitely are required in many scenarios, but these systems are unable to complete the job. Here’s why:

- Many manufacturing processes are open, which precludes the placement of a hood directly at the point where the dust is generated.

- Even if a hood can be installed at a point of origin, there are other areas in a plant where dust collects. Consider a timber mill, where the dust sticks to the boards themselves throughout the process. Where does that go? Typically on the floor or the equipment. This dust then gets kicked up by a forklift or personnel, reintroducing it into the plant’s air.

- Then there is the issue of compressed air to blow dust from the equipment, which frequently happens. Part of this dust will inevitably land on overhead structures.

- Dust gets into the plant in the filter suction ductwork system itself. The abrasion of the dust wears out the parts of the filtration suction duct, so you can have some reentry into the ambient air due to leaks in the suction duct.

5 High velocity air barriers increase the risk of developing combustible clouds.

A typical cooling fan definitely kicks up dust in a way that can be dangerous. A clean fan is something else entirely.

A clean fan robotically leverages high velocity air patterns to disrupt the thermal currents that carry dust upward and keep holding that dust in the ambient air. It is a controlled way to direct the airflow that creates an overhead barrier so dust doesn’t collect on overhead structures.

The first time a clean fan is used, a significant amount of accumulated overhead dust can temporarily change the ambient air quality. But this is a one-time occurrence, and is accomplished in a controlled setting such that a dangerous situation is minimized if not eliminated. When a clean fan is used on a continuous basis, the number of particles in the air can be significantly reduced by causing dust particles to fall to the ground faster, where they can be swept away through normal floor-cleaning procedures.