The National Fire Protection Association (NFPA) set the standard for use and testing of PPE, and issued changes to NFPA 70E standards for electrical work (www.nfpa.org to obtain a copy). One of the most recent editions of the standard requires protective clothing and PPE for protection against arc flash.

Dynamics of an arc flash

An arc flash is a rapid release of energy due to improper grounding between live electrical current and a neutral or ground connection. Arc faults are generally limited to systems where the voltage is in excess of 120 volts. Lower voltage will not normally sustain an arc. Air becomes the conductor as the energy seeks a proper ground. The earth itself is a strong neutral source that attracts and releases arc flash energy.

Anything between the points of the arc can be vaporized and cause the formation of a continuous conductive path between the electrodes, creating a better conductive path than air. The increasing current will cause a further increase of the temperature and cause the transformation of the heated air between the end points. This chain of events is the basic development of a typical arc flash incident — that can produce more explosive energy than a pound of TNT. The blast from the electrical arc causes chaos and damage to the surrounding area. Worker injuries can be critical, sometimes fatal if caught in a blast area. Even at a distance, heat is still a dangerous hazard from an arc flash. Arc temperatures can reach up to 35,000°F (19,426° C). The intense heat can cause second or third degree burns and can sometimes be fatal.

Unique exposure

The intense energy and short duration of an electrical arc flash represents a very unique exposure. NFPA 70E requires a Flash Hazard Analysis of each task where an element of an electrical hazard is present. This analysis is the responsibility of the employer. NFPA provides tables from which a protective plan can be assessed. The analysis shall determine a flash protection boundary and personal protective equipment (PPE) requirements when working in or outside that boundary.

The arc flash boundary is the distance at which a person working within this boundary at the time of the arc flash may receive permanent injury if not properly protected by flame-resistant PPE. Research shows that permanent injury results from an incident energy of 1.2 calories / centimeter2 (cal/cm2) or greater than the skin’s surface. This boundary cannot be determined by a casual survey of electrical equipment. The only practical way of determining this boundary is to calculate the magnitude of the arc to estimate how long the arc will last and then how far away a worker must be to avoid receiving this energy.

Clothing requirements

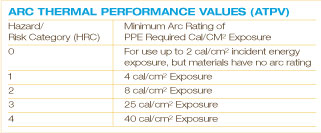

Employees working within this boundary are required to wear clothing that is suitable for protection for the determined hazard risk category. NFPA 70E provides a chart (see Arc Thermal Performance Values (ATPV) chart below) to determine the required arc thermal performance values of PPE for the corresponding Hazard Risk Category.

After the HRC has been determined and documented, the proper PPE can be selected. PPE must be properly rated according to the HRC, and clothing is required to be labeled with the arc rating it is approved for as well as whether the item meets ASTM F 1506 requirements. Employers and workers should be aware that clothing with HRC ratings protects workers from the heat of an arc explosion but NOT from electrical shock.

With standards set to protect workers, innovation in comfort and function is trying to keep step with the changes in the industry. Items such as seamless knit gloves made of oxidized thermally stabilized fiber offer protection plus flexibility, dexterity and comfort.

Of course with any safety issues, users should consult NFPA 70E for complete and thorough information.