Home » Keywords: » manufacturing

Items Tagged with 'manufacturing'

ARTICLES

Learn how to analyze and identify hazards to protect workers

Read More

Ensuring worker safety during the holiday season

A guide for to compliance in industrial, warehouse, and manufacturing settings

December 21, 2023

The changing face of manufacturing

Keeping safety at the forefront as automation increases and labor shortages continue

December 19, 2023

OSHA finds 3M responsible in worker death at manufacturing plant

Company fined more than $300K for preventable workplace fatality

November 10, 2023

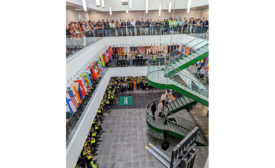

Forklift company Combilift focuses on sustainability

At Irish HQ, facility making inroads in quest to improve environmental impact

October 17, 2023

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest safety trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing