Exposure to high levels of radiation can be dangerous. Because radiation is odorless and invisible, those who must work with radioactive materials need special equipment to ensure their safety and the safety of those around them. Therefore, speed, accuracy and reliability are more important than ever in radiation detection instruments used to assess radioactive threats and to guide life-saving decisions.

All personnel who work with radioisotopes need different detection and measurement devices. Knowing more about radiation and how to detect it can help keep industrial hygienists, first responders and the public safe from overexposure.

Radiation protection and detection

Radiation is part of daily life on our planet. Ionizing radiation is all around us. There’s naturally occurring cosmic radiation from space as well as radioactive material in the ground. Ionizing radiation represents one of two forms of radiation and the one known to damage cell structures and increase the risk of cancer. Exposure to elevated levels of radiation for extended periods of time can be life threatening.

The fundamental principle of radiation safety is to reduce exposure to ionizing radiation and its source. The goal is to maintain exposure to As Low As Reasonably Achievable, or ALARA. The three factors influencing radiation dose are time, distance and shielding, so the best ways to protect yourself are to limit your time near the radiation source; put distance between you and the source; and/or increase the amount of shielding material between you and the source.

Types of detection equipment

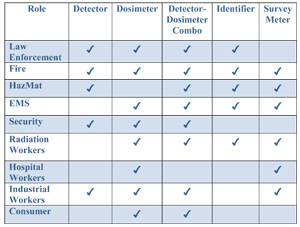

For those who need to work with radioactive materials, deploying specialized radiation-detection equipment is key to ensuring safety. There are four main types of radiation-detection instruments:

1. Personal radiation detectors

A personal radiation detector is a small pager-like device. Its main purpose is to alert the wearer to the presence of radiation as quickly as possible. Detectors typically sense gamma radiation or gamma and neutron radiation. Personal radiation detectors typically cost between $600 and $1,200 and last many years.

2. Dosimeters

A dosimeter accurately measures the accumulated radiation dose that the wearer has received. Dosimeters can measure gamma, alpha, beta and neutron radiation doses, but most electronic personal dosimeters measure only gamma radiation because it is the most likely type of radiation exposure. Electronic personal dosimeters are less expensive than personal radiation detectors and range from $200 to $500 per unit.

3. Identifiers

An identifier uses the differences in radiation emission energies to determine which radioisotope is present. Identifiers are mainly used to identify an unknown radioactive source or contamination. Identifiers are expensive, and a single unit can cost more than $10,000.

4. Survey Meters

Survey meters measure radiation levels using the same radiation sensors employed in detectors and dosimeters. These have a probe that’s held in one hand, while the meter box is held in the other. Each probe is specifically tailored to a particular type of radiation, and can measure gamma, neutron, alpha or beta radiation levels. Cost of a survey meter can range from $1,000 to $20,000.

Selecting appropriate detection equipment

Most people only need one or two types of devices, which, when used properly, can make their jobs easier and safer.

Workers in industrial facilities with radioactive materials

Personnel entering areas where the radioactive material is stored should wear a personal radiation detector to alert them of any leaking sources and high dose rate areas. Workers at refineries and chemical plants must wear intrinsically safe equipment, especially during plant turnarounds.

Radiation workers

Each radiation worker should wear a dosimeter when entering a radiation area. Dosimeters are used because it is known that there is radiation in the area, and by law the dose to each worker must be carefully tracked.

First responders

First responders need the most rugged and fastest responding equipment possible that includes intrinsic safety, water, shock and EMI resistance, ease of operation while wearing several layers of gloves, and illuminated, easy-to-read displays. Since HazMat responders may be exposed to more significant amounts of radiation, a detector-dosimeter combination instrument is ideal. A survey meter or detector should be used to determine a safe distance from the source.

Detection, prevention and safety

The proper use of appropriate radiation detection can help protect the industrial hygienist and the public. New technologies have been developed to organize, simplify and better meet the challenges that face you on a daily basis.

Selecting the right equipment can be challenging. Things to consider when selecting a radiation-detection instrument include:

• How important is speed-of-response for your application?

• Will the device be used in a rugged or harsh environment?

• How important is portability?

• How important is ease of use?

• Do you want readings on radiation levels?

• Do you want to track exposure over time?

• Are you interested in identifying specific radioisotope types?