While classification of chemicals sets the stage and the consistent 16-section format safety data sheet will be a major vehicle to transmit information, label elements with mandatory phrases best reflect global harmonization. Example of label elements is shown in Figure 1.

|

| Figure 1 - OSHA HazCom Label Elements (example) |

Training and hazard classes

Section (h)(1) of the Hazcom standard allows employers to provide information and training either by categories (classes) of hazards or chemical-specific training, e.g. SDSs. Worksites with few chemicals will probably elect to train through SDSs while worksites with many chemicals may find training by hazard classes to be more expedient. Figure 1 is one of 30 hazard classes found in Appendix C.

Precautionary statements

You may determine how ready your worksite is for GHS by knowing which hazard classes your chemicals fit into and then comparing precautionary statements within label elements. If you have addressed all the precautions, then you’re ready for GHS. Precautionary statements were developed and approved by an international group of experts and describe measures that should be taken to minimize or prevent adverse effects that result from exposure to hazardous chemicals.

For example, if some of your worksite chemicals are classified as “Sensitization — Skin” (Appendix C.4.7), then a uniform program, locker room with showers, and special laundry service is expected. Why? One of the precautionary statements for prevention for this class of chemicals is, “Contaminated work clothing must not be allowed out of the workplace.”

Special knowledge

|

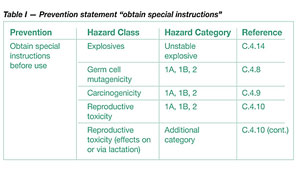

| Table 1 - Prevention statement "obtain special instructions" |

You may have to obtain special knowledge to be ready for GHS. For example, in Figure 1, one of the prevention statements for the class of unstable explosive is, “Obtain special instructions before use.” International experts have determined that unstable explosives are uniquely dangerous and require input from someone who may have expert knowledge about the hazard. Be aware that other dangerous categories of explosives, such as those that have a mass explosion hazard or severe projection hazard, do not require special instructions before use.

Special hazard classes

Table I shows each of the hazard classes in Appendix C that contain the “Obtain special instructions before use” prevention statement.

Put yourself in the mind of the GHS international experts. Why are chemicals that may be mutagens, may cause cancer, or have reproductive toxicity uniquely dangerous and on par for prevention with an unstable explosive? If your worksite has chemicals that fit into one of the hazard classes shown in Table I, special knowledge and a special worksite safety and health program are expected.

Exposed, concerned or feel unwell

Several hazard classes in Appendix C contain precautionary statements for response that recommends that medical advice/attention or a poison center/doctor be contacted if an employee is “exposed, concerned, or feels unwell” — each of which are subjective thoughts or symptoms. Examples are chemicals classified as Specific Target Organ Toxicity (C.4.11 and C.4.12).

Care must be taken during training to inform employees when help should be sought outside of the workplace. For example, if an employee swallows a chemical classified for Acute Toxicity — Oral (C.4.1), then an immediate call to a poison center/doctor is warranted. However, if an employee simply detects the odor of a chemical classified, for example, as Specific Target Organ Toxicity (C.4.11), the slight exposure doesn’t warrant a call for assistance outside the workplace.

It is not unusual for an employee to be “concerned” about a chemical, e.g. carcinogen (C.4.9), but you need to make clear during training what level of concern should cause an employee to “Get medical advice/attention.” Lastly, research shows that upwards of 80 percent of a population may not feel well at sometime during a month. Training should emphasize what health symptoms and signs relate to overexposure specific to chemicals being used.

Storage

Several classifications of chemicals, e.g. Toxic to Reproduction (C.4.10), have the precautionary statement for storage, “Store locked up.” You may take this precaution literally and put the chemical in a cabinet under lock and key. However, the intent of the recommendation is to prevent unauthorized access to the chemical. A secured workplace that requires an employee to have a badge or device to enter and where employees are supervised in work areas may qualify as “store locked up.”

Label elements in SDS

Label elements, e.g. mandatory phrases in Appendix C, will also appear in SDSs. To be ready for GHS, EHS pros should understand that the heart of Hazcom is found with information for label elements.