Hand injuries are among the most common work-related injuries. Of these, nearly one-third involve cuts or lacerations. Such injuries are also becoming more costly. According to the National Safety Council, a single hand laceration can cost over $12,000 in direct and related costs; if a tendon is severed, the cost can approach $70,000.

Of course, cut protection is more than just cut resistance. It’s a combination of glove attributes that also include abrasion resistance, grip, and dexterity—as well as workplace factors like machine guarding, workplace set-up, working conditions, and worker training. Wearing the right glove at the right time is vital. The new standards will help you choose the right protection with greater precision and accuracy than before.

Current standards

To help guide PPE purchasers, both ANSI and the European Union (EU) have developed standards for cut-resistant materials.

The U.S. standard is ANSI/ISEA 105 (“American National Standard for Hand Protection”), which rates gloves and other cut protective clothing on a consistent numeric rating scheme for mechanical, thermal, chemical, dexterity, and other performance criteria.

Although the use of the ANSI/ISEA selection criteria is not mandatory in the United States, most safety managers choose to follow it in selecting the right protection for their employees.

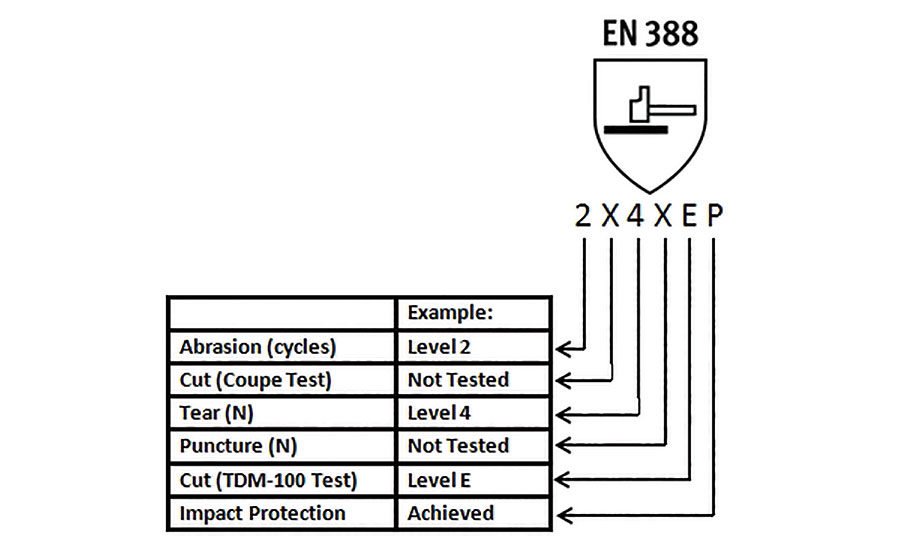

The EU standard of EN 388 (“Protective Gloves Against Mechanical Risks”) rates gloves and other cut protective clothing for abrasion, cut, tear, and puncture resistance. Beyond the European Union, this standard is also recognized globally.

While these standards provide a useful guide, they are not interchangeable. Each uses a totally different test method and numeric performance rating. As a result, there is a growing need for a more consistent testing method and ratings that take into account recent advances in cut-resistant yarns and technologies and provides more specificity when choosing PPE.

Why change is needed

ANSI/ISEA 105: In recent years, as new yarns and new technologies have been developed, performance of cut-resistant gloves has improved tremendously. There are now more options in the 1500-3500 grams range and above 3500 grams. The increased granularity within the new levels allows glove manufacturers to identify gloves with greater degrees of cut protection than before.

EN 388: The proposed changes to the current EN 388 standard focus on improved reproducibility, specific to the cut and abrasion parts of the standard. With this focus, the EN 388 has adopted the ISO 13997 TDM test as a more reliable test method. Although the Coupe test has been retained for now, it may be removed at the beginning of the next five-year revision cycle. Back of hand impact protection requirements have also been included.

What you need to know about the new standards

ANSI/ISEA 105: The updates to the ANSI/ISEA 105 standard were focused primarily on the cut performance portion of the standard. The new ANSI/ISEA 105-16 version contains an increase in cut performance ratings from five to nine levels, as shown in Figure 1. The new standard will reference only the TDM Test Method, based on the ASTM F2992-15 standard, while discarding the CPPT method.

Although the use of the ANSI/ISEA selection criteria is not mandatory in the U.S., most safety managers use the standard as a guide to provide the right protection for their employees. Because glove manufacturers are not required to change from the ANSI/ISEA 105-11 to the new ANSI/ISEA 105-16 standard within a certain timeframe, there will be a mix of identifications of performance in the marketplace.

Additionally, there is also a test method in the standard for resistance to puncture from a hypodermic needle. Previously, puncture resistance was measured with a stylus, but the committee now recognizes an increasing need to test for hypodermic needle resistance for specific applications.

EN 388: Proposed changes would affect the EN 388 standard in a number of significant areas. These include acceptance of the ISO 13997 (TDM) cut test method, amending the Coupe test to take into account dulling of the blade, change of the abrasive paper, and the addition of an impact protection threshold, among others.

Use of the ISO 13997 (TDM) test as an equivalent method is a major step. Under this change, cut performance achieved using the TDM will be more aligned to the ANSI/ISEA 105 method. Levels rated though the TDM method will be lettered (A through F) to avoid confusion with the Coupe method, which will still use numerical labels.

Calibration of the TDM machine is also improved. Control over sharpness of the blade has been enhanced, and an equation has been created to determine the maximum number of cycles at which test should be stopped to measure dulling. If dulling is detected, the TDM test becomes the new reference test method. Results obtained from the Coupe method may optionally be reported, but an addition to the “Instructions for Use” or the manufacturer’s instructions must state there was dulling of the blade, the Coupe test results are for reference only, and the TDM test results are the final report of the material’s performance.

The abrasion test segment has changed the type of abrasive paper to be used, which will result in lower performance for an equivalent textile, potentially by up to 1 level. Figure 1 shows what the changes may look like for a typical test.

Any changes to EN 388 will be compulsory, which is different than that of ANSI/ISEA. Even with the addition to the EN rating system of the ISO13997 method, there will continue to be different identification markings and performance rankings on gloves tested using the EN388 method compared with those tested by the ANSI/ISEA method. The use of new markings under the ANSI/ISEA method, the addition of new markings for the CE ratings under the EN388 test method, and the continued use of different types of test equipment between the two standards will continue to promote confusion in the marketplace around proper PPE choices.

When will changes take effect?

In North America, the new standard went into effect at the end of January and is already being used by industry members. The new ANSI/ISEA 105-16 can be downloaded from the ISEA website at: https://safetyequipment.org/standard/ansiisea-105-2016/

In Europe, the proposed EN388 changes are currently out for ballot, and members have until early June to return their votes. Given a positive vote, the new standard should become effective at the end of June or early July, with publication of the new standard shortly thereafter.

2 Ibid