In the 21st Century workplace, hazardous chemicals are a fact of life.

About 650,000 hazardous chemicals are used in more than three million facilities across the United States, and more than 95 percent of U.S. employers are serious about creating safer workplaces, according to OSHA.

For the past 20 years, OSHA’s Hazard Communication Standard has provided a generic framework for worker protection, but the standard and the workplace have not kept pace with new developments and technological advances.

Today, for example, there are user-friendly software systems that can give an organization’s workers 24/7 access to up-to-date material safety data sheets (MSDS) from virtually any location in the world. Yet, workers at many facilities still must pore through think binders of paper MSDSs to find critical information about hazardous chemicals at times when time may be the enemy. In addition, there are no guarantees that the paper documents contain the latest information or that they are written in clear, non-technical language.

GHS’ potential

The Globally Harmonized System for Hazard Communication (GHS) has the potential to significantly enhance hazard communication. It is designed to improve the quality of chemical communications methods by establishing standardized requirements for hazard evaluation, MSDS and labels.Progress on the 15-year-old United Nations initiative has been slow, albeit steady in the United States. There has been some movement recently at some of the federal agencies involved in determining how the United States can adopt the GHS without compromising the level of protection afforded by existing systems.

OSHA proposal due

OSHA has completed its advance notice of proposed rulemaking (ANPR), which is now undergoing a courtesy review by the U.S. Office of Management and Budget (OMB). Once the OMB review has been completed, the proposed rulemaking could be posted for public comment, possibly before the summer, an OSHA official said.ORC Worldwide, an international environmental and worker safety organization in Washington, D.C., has been closely following the GHS. The ORC believes the new system would be good for business, said Ann Brockhaus, an occupational safety and health consultant who also serves as president of the Society for Chemical Hazard Communication (SCHC).

“Although the notion of complete harmonization globally is probably a long-range goal, in the short term, making hazard communication consistent with the GHS will help standardize the process in the United States,†she said. “Our hope is that it will also take global companies a long way toward being able to prepare just one MSDS and one label worldwide.â€

Other agencies involved

Along with OSHA, the other federal agencies involved in U.S. adoption of the GHS are the Environmental Protection Agency (EPA), the Department of Transportation (DOT) and the Consumer Product Safety Commission (CPSC).The DOT is probably the furthest along of the four agencies. Rules regulating the transportation of hazardous goods have been aligned with the GHS for some time and the final rule for introducing GHS into hazardous materials regulations is expected by the end of 2006.

OSHA is probably next in line. The ANPR is intended to generate feedback from stakeholders on how they would like to see the GHS implemented. The goal at OSHA is to have a final rule by 2008.

The primary issue at the EPA is pesticide labeling. The EPA has not reached the ANPR stage, but has issued a white paper that outlines implementation planning issues for its Office of Pesticide Programs. The white paper outlines the anticipated benefits of harmonization, such as:

- Enhanced protection of human health and the environment: GHS will help ensure more consistency in the classification and labeling of all chemicals, thereby reducing risk in the handling and use of chemicals in transport, in the workplace and by consumers.

- Sound management of chemicals worldwide: GHS will provide a harmonized basis for the first step in sound management of chemicals — identifying and classifying hazards and communicating them. This will be particularly useful for countries without well-developed regulatory systems.

- Trade facilitation: GHS will reduce costly and time-consuming activities needed to comply with multiple classification and labeling systems, promoting more consistency in regulation and reducing non-tariff barriers to trade.

Last year, the CPSC started a review of differences between the GHS and current U.S. standards for consumer product labeling. The study is the first phase of the commission’s effort to determine how to best implement the GHS for consumer products.

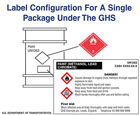

Figure 1: The GHS would establish standardized requirements for hazard evaluation, MSDS and labels. Source: ESS

Adopted in increments

Fortunately, the GHS can be adopted in increments. OSHA would not have to wait for the other agencies in order to align its Hazard Communication Standard with the GHS. One has only to review the history of the standard to see why this is important, particularly from a domestic standpoint.During the original rulemaking, chemical manufacturers urged the government to allow each company to decide how it should communicate chemical information on its own labels and MSDSs. Meanwhile, some unions and chemical users thought a more standardized format and descriptions would make labels and MSDSs more effective.

Ultimately, the manufacturers prevailed and while most of them produce clear, readable and informative labels and MSDSs, officials say, some data sheets are inconsistent, others are incorrect and some even appear to be designed to hide information rather than reveal facts that could protect workers.

During testimony at a Senate Subcommittee on Employee and Safety Training hearing on hazard communications in the workplace not long ago, Michael J. Wright, director of the United Steelworkers of America’s Health, Safety and Environment Department, provided MSDSs for a type of refractory fiber from two different manufacturers. Both warnings are legal under the current standards.

One said, “Warning: similar material has been shown to cause malignant and non-malignant neoplasms in experimental animals exposed via interperitoneal installation. As this route of exposure does not mimic the human experience, the significance of this finding is uncertain.â€

The other said, “Warning: causes cancer.â€

Automated MSDS benefits

The International Labor Organization estimates that two million people die each year from workplace injuries and disease. Worldwide adoption of a single unified system that combines the best elements of existing national systems could prevent many of these deaths.As the cornerstones of hazard communication, accurate, concise and current material safety data sheets are among the primary keys to success in virtually any worker safety program. And, there are environmental, health & safety (EHS) software systems available today that automate and streamline the entire MSDS process. The better solutions use the internet or the intranet to bring MSDS management to the desktop. In an emergency, an employee can have access to the latest and available information about a particular chemical in seconds.

Under the GHS, the software could provide the means for ensuring that workers across the globe have access to information that could further reduce the likelihood and severity of workplace incidents. These solutions would also save time and virtually eliminate distribution costs by serving as a central database of globally standardized MSDSs for all chemicals at any given facility.

Marc Dillonis director of consulting services andJudith Colemanis manager of training at ESS. Both are experts in the field of automated MSDS management software. ESS provides Operational Risk Management software and services for Environmental, Health & Safety (EHS) and Crisis Management. The company has provided solutions to more than 17,000 businesses, government agencies and other organizations worldwide.

SIDEBAR: What are the advantages of harmonization for the U.S.?

Harmonization of hazard classification and labeling will promote regulatory efficiency and facilitate trade without lowering the level of health and environmental protection afforded by current U.S. laws and regulations. Greater consistency in chemical hazard classification and labeling requirements worldwide will make it easier for companies to comply with applicable standards and reduce the costs associated with the need to follow different rules in different countries. Common classification criteria, labeling and other information materials will help companies and countries provide better, more consistent information about chemical hazards, thereby promoting safer transport, handling and use.U.S. participation in the GHS would be voluntary, and we [in the U.S.] would be able to adapt the system as appropriate to our circumstances. Where we now have classification, labeling and related requirements imposed by various domestic regulatory agencies, harmonizing in the global context may also improve domestic coordination. The GHS will in no way supersede the health and safety standards contained in U.S. laws and regulations, or make decisions that are properly within the purview of U.S. agencies. Rather, it would serve as a nonbinding mechanism to promote consistency.

Source: OSHA’s “Harmonization of Hazard Classification and Labeling Questions & Answersâ€