|

| Click to enlarge |

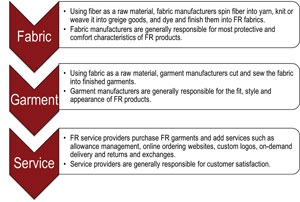

Many steps and stakeholders are involved in designing, producing, selling and delivering arc/flame resistant clothing. The key players can be broken into three interconnected components: fabric manufacturers, garment manufacturers and service providers. Each piece of the bigger picture plays a profound role in the total experience.

The process starts with fabric manufacturers, who spin fiber into yarn and ultimately into finished arc/flame resistant fabrics sold to garment manufacturers.

Garment manufacturers, the second major player, purchase finished arc/flame-resistant fabrics and produce finished garments. Garment manufacturers design the garments and cut and sew the arc/flame-resistant fabrics into wear-ready products.

Finally, service providers connect finished garments with end-user wearers by purchasing arc/flame-resistant garments from garment manufacturers and adding customized services to the overall package.

Fabric manufacturing

The fabric manufacturing process is the first building block in the arc/flame-resistant clothing experience. Two categories of fabrics are available in the marketplace, inherent and treated. Fabrics that are inherently flame resistant are made using fibers that are innately flame resistant, while treated fabrics undergo a process during manufacturing to impart flame resistance. Before they can be sold to garment manufacturers and made into protective clothing, fabric manufacturers must arc test and/or flash fire test all finished fabrics to ensure their protective characteristics meet industry standards.

The fabric manufacturing process plays a critical role in the safety and performance of a finished garment. In fact, the fabric supplier affects as much as 90 percent of the overall safety of an arc/flame-resistant garment, controlling factors such as flame resistance, durability of flame-resistant properties, arc flash protection, and flash fire protection (if applicable).

The fabric manufacturing process shapes additional features of finished garments. The fabric dictates softness, degree of warmth and breathability, impacting the finished garment’s comfort. Another key attribute determined by fabric is shrinkage; arc/flame-resistant fabrics will generally shrink over time, but manufacturers strive to achieve shrinkage consistent with traditional everyday clothing. Fabric properties also control wrinkle-resistance and wear life. Together, these attributes affect both fit and durability.

Garment manufacturing

Garment manufacturers buy finished arc/flame-resistant fabrics and make them into field-ready garments. Garment manufacturers generally take one of two approaches to manufacturing: made to stock or made to order. Made-to-stock garments are generally continuously made and readily available and feature economical pricing and on-demand delivery. Made-to-order garments, on the other hand, offer increased flexibility in design but generally come at a premium and are characterized by augmented lead times.

The quality of the finished garment is directly related to the quality of the manufacturing process, affecting characteristics like fit, durability and protection. The garment manufacturer is responsible for product development and design, making decisions about a garment’s style, features (such as pockets and zippers) and garment construction. The garment manufacturer is directly responsible for the way a finished garment fits. Premium garment construction features, such as double- and triple-needle stitching and reinforced stress points, are dictated by the garment manufacturer and improve the way the garment wears over time.

The manufacturer is responsible for appropriately labeling the garments to communicate its protective characteristics.

Service providers

Service providers bring the first two components together, connecting finished products with end users. Because they put a face on the product and directly manage the total experience, service providers typically play the largest role in overall customer satisfaction. There are four predominant types of arc/flame-resistant garment distribution models, offering varying degrees of service: managed direct-buy program, storeroom program, rental laundry program and retail.

Managed Direct Buy Program providers enable customers to provide stipends for individual employees to purchase necessary arc/flame-resistant clothing. Generally, these companies provide services such as product selection, custom catalogs, logo capabilities, customer service, customized reporting and invoicing, online ordering, returns and exchanges, and maintain inventory for optimal delivery.

Some providers offer spend control mechanisms, such as allowance management — a dollar stipend for employees to order authorized items, allotment management — a fixed quantity of authorized items employees can order, or supervisor approval — an automated system whereby supervisors authorize an employee’s purchase needs. Advanced suppliers maintain comprehensive data history, including an OSHA audit trail, and expenditure enforcement.

Rental or lease-and-launder providers supply garments and facilitate regular pickup, laundering, and drop-off of clothing for a weekly fee. This model is advantageous in situations when workers are exposed to particularly dirty work conditions, where on-site cleaning is preferable to home laundering.

Storeroom providers typically maintain high inventory levels for on-demand product distribution. This model is maintained through bulk purchase and bulk delivery, but is limited in product variety, and subject to logistical challenges in facilitating distribution. Some companies take on management of products on-site in a storeroom as well.

Retail providers — bricks and mortar — are especially common in energy-rich areas of the country, where arc/flame-resistant clothing can often be found within traditional stores. This model provides immediate access to product but typically involves a lower level of service due to challenges with expenditure-enforcement and maintaining an OSHA audit trail. Increasingly, online retailers are gaining popularity.

Each component of the arc/flame-resistant clothing value chain has an important role in the overall user experience. When structuring your protective apparel package, understanding and thoughtful consideration of each component will enable you to actively participate in shaping your own experience — and that of your employees.