In response to this trend, ORC formed a “Fatality and Serious Injury Task Force.” More than 70 fatality and near-fatality cases have already been reported by task force members, allowing ORC to do some preliminary analysis on the root causes of these incidents. Before discussing these findings, however, I want to explain briefly why many safety professionals are focusing on serious injury and fatality prevention.

Challenging the Heinrich Pyramid

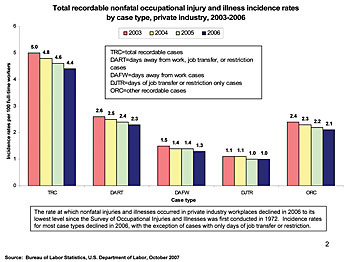

The received wisdom now called into question is the belief in a direct relationship between unsafe acts, minor incidents, and serious injuries. It can be traced back to the 77-year-old Heinrich Pyramid, or safety triangle, first discussed in H.W. Heinrich’s 1931 book, Industrial Accident Prevention: A Scientific Approach (see figure one). The theory predicts that for every 300 near-miss incidents there will be 29 minor and one major injury. Although the specific numbers in the pyramid have never been scientifically validated, the concept has appealed to safety professionals for years as intuitively plausible.Skeptics of the Heinrich Pyramid argue that the Bureau of Labor Statistics data do not appear to support the theory. Since 2003, every major measure of OSHA recordable nonfatal occupational injury and illness rates has declined: total recordable cases; days away from work, job transfer, or restriction cases; days of job transfer or restriction only cases; and other recordable cases (see figure two).

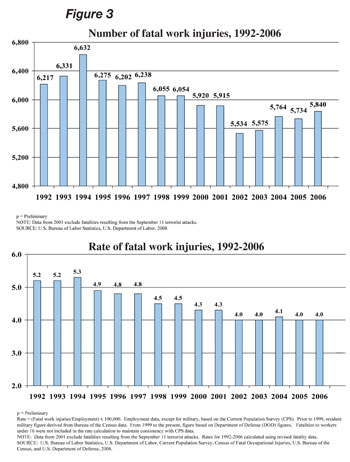

If Heinrich’s theory is correct, one would expect this steady decline in total injuries to be accompanied by a decline in the most serious kinds of injuries. But this is not the case; the number of workplace fatalities increased from 2003 to 2006 (the last year for which complete data are available), while the rate of fatal injuries did not change (see figure three).

In the second edition of Safety Management, the late and venerable Dan Petersen agreed that the types of accidents resulting in temporary disabilities are quite different from those resulting in permanent total disabilities or fatalities. “There are different sets of circumstances [and causes] surrounding severity.”

Preliminary results

So far a total of 17 companies have shared data on 72 fatality and near-fatality cases with ORC. While this sample size is too small to be statistically definitive, it is large enough to be suggestive. We believe these results can be used to guide future research as well as ongoing risk-reduction strategies.The first noteworthy feature of the data is that almost half of these incidents (33) involved contractors as opposed to regular employees. Although we do not know the overall ratio of contractors to employees at these organizations, it is likely far below 50 percent. This is evidence that contract workers face significantly higher serious injury risk than do regular employees.

We also found important differences among contractors and employees regarding the type of work involved in these incidents. Operations led to four times as many incidents for employees as compared to contractors, while contractors were far more likely to be involved in incidents involving field service and construction/renovation work. Overall, maintenance and service tasks accounted for the largest number of incidents (14).

Perhaps the most significant findings point to a possible mismatch between fatality incident investigation findings and corrective actions taken to address the situation.

For example, poor equipment design, hazardous conditions, and machinery were all essentially tied for third place (cited 55 to 56 times) as contributing causes to these incidents. But substituting less hazardous tools or materials came in last as a corrective action, cited just three times while equipment modification was cited 28 times. Retraining (41 citations) and procedure modification (40 citations) were the most frequently cited corrective actions.

Conclusion

The results of the ORC Fatality and Serious Injury Task Force Survey have convinced us that as professionals we must change how we view:- The relationship between incident investigations and corrective action;

- Employee behavior and risk management;

- Employee behavior and engineering controls.

Through its consulting expertise, networking opportunities and a range of other specialized services, ORC Worldwide today helps more than 150 leading corporations achieve safety, health and environmental excellence (www.orc-dc.com).