Understanding the type and concentration of weld fume in a facility is the first step in either maintaining or achieving compliance. Industrial hygienists work with companies to conduct exposure assessments through site evaluations and air sampling, which can be a company’s baseline for change. In most cases, improving air quality isn’t limited to one solution, nor is it a one-time event — it is an ongoing process that requires continued attention.

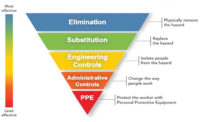

Following OSHA’s Hierarchy of Controls for welding fume control, companies have four prescribed steps they can employ to establish a clean, safe and compliant work environment:

1. Process modification/substitution – low manganese wires, new materials, etc.

2. Engineering controls – source capture (fume extraction systems), fume guns

3. Work practice controls – training, new work practices

4. Personal protective equipment (PPE) –respirators

While evaluating which step(s) are feasible for the welding environment, it’s important to establish a collaborative approach to the process, involving all levels of the operation from management to the welding operator. A group effort not only helps ensure success, but also positions the company for greater efficiency overall — a safer work environment equals more productive employees and higher quality results.

Companies should include weld fume controls in their long-range planning process to help streamline implementation from a practicality to budgetary perspective.

Adequate ventilation through source capture

If modifying the welding process as a first attempt in reducing welding fume exposure is not feasible or does not lower concentrations enough, engineering controls, such as fume extraction equipment, should be considered. A source capture solution should provide high enough airflow to remove the weld fume, keeping levels below allowable limits. OSHA refers to this as “adequate” ventilation. It should be noted that there are no set levels from OSHA for the cubic feet per minute of airflow for a given source capture unit.

Ultimately, companies have to be accountable in terms of meeting requirements via air sampling with the selected solution. Partnering with a manufacturer that can help design and engineer custom systems for unique challenges and/or a certified industrial hygienist is recommended. Source capture selection is based on the variables within a welding space, as well as the application. For applications in a small weld cell, implementing either a portable or a mobile floor fume extraction system works well since the welding operator will be relatively stationary. In robotic welding cells, a centralized fume extraction system with automation hoods is a good choice. Selecting the right filter is also important for all types of source capture, and surface loading filters are typically the most effective and longest lasting.

Employee involvement can increase compliance

Work practice controls involve changes to workplace procedures, policies and the way people work, often augmenting other steps within OSHA’s Hierarchy of Controls. Examples include:

- Training that covers welding best practices to minimize the creation of excess spatter and over-welding, decreasing fume generation.

- Proper body positioning so the welding operator’s head is out of the plume and airflow moves fumes away from the breathing zone.

- The addition of rotating fixtures or adjustable weld tables to keep the welding operator in a consistently protected position.

- Properly fitted welding helmet with a large viewing area and clear optics to allow optimal visual of the weld (without moving too close).

- Vision testing to confirm the welding operator is capable of viewing the weld at a safe distance, along with the addition of magnification or prescription lens to the helmet as needed.

Implementing PPE

Appropriate PPE, or in the case of weld fume management, respirators, can aid in the reduction of weld fume exposure. Respirators are ideal in protecting welding operators who require mobility within the welding environment, such as those working on large weldments. Selecting the correct respirator is dependent on the work environment and welding protection needs; a certified industrial hygienist can assist in this process. Per OSHA, all respirators are required to be certified by the National Institute for Occupational Safety and Health (NIOSH). Respirators common in welding applications, along with key considerations, are listed below:

- Disposable masks: a flame-retardant mask material is ideal for welding.

- Half masks: select those that feature low-profile filters so the mask will fit underneath a helmet without obstructing the user’s field of vision.

- Powered air purifying respirators (PAPRs): be mindful of the overall unit weight to alleviate lower back strain and consider all tasks the welding operator will use the system for to choose the correct helmet assembly.

- Supplied air respirators (SARs): carefully consider the air control device position so that ergonomically it aligns with the welding operator’s task; some units feature devices that can be adjusted either horizontally or vertically to enhance user customization.

OSHA requires companies to establish and implement a written respiratory protection program for both voluntary and mandatory respirator usage, although the requirements for each will vary. The program requires medical evaluations to be conducted for all respirator users, which is done through the completion of an OSHA questionnaire that is reviewed by a licensed health professional. Based on responses to the questionnaire, a follow-up examination may be necessary. Companies also need to document fit testing, for mandatory tight-fitting respirator (half mask) usage. Qualified personnel should administer testing before initial respirator use and annually thereafter, or whenever a change occurs with the welding operator or environment. OSHA requires companies that mandate respirator use to conduct training that explains:

- Why the respirator is necessary and how improper fit/maintenance can negatively impact its performance.

- Limitations and capabilities of the respirator.

- Use of the respirator in emergency situations and what to do if the respirator fails.

- How to inspect, put on and remove, use and check the seals of the respirator.

- Maintenance and storage procedures.

- How to recognize medical signs and symptoms that may limit or prevent the effective use of respirators.

- General requirements of 29 CFR OSHA 1910.134, Occupational Safety and Health Standards, Personal Protective Equipment, Respiratory Protection.

As with fit testing, training should be completed prior to use and then annually or sooner if there is a change in the welding process; for example, the implementation of new welding wires, an alternate welding process or new respirators being used.

Final considerations

Before taking any steps to implement a weld fume management solution, companies should always establish a baseline for improvement by having the appropriate air sampling conducted and then create a plan of action for moving forward. Included in the plan should be a schedule for retesting air quality based on the appropriate timeline and initial sampling results. A certified industrial hygienist can help. Welding operator training should also be emphasized as an essential part of the plan in order to establish and maintain a clean, compliant and efficient welding environment. The more collaborative the effort, the better the results.