If something doesn't bring you joy, popular wisdom advises to get rid of it. Yet supply chain managers don't have that luxury. Everything in their inventories has a reason to be there. That means organizing their spaces is much more complicated than for the average homeowner- not to mention a lot more important.

How these facilities are organized can significantly impact the efficiency and profitability of an organization. However, there are common mistakes professionals could make that hurt the overall performance of their spaces. Identifying and resolving these errors is critical to better ensuring the warehouse is functioning optimally.

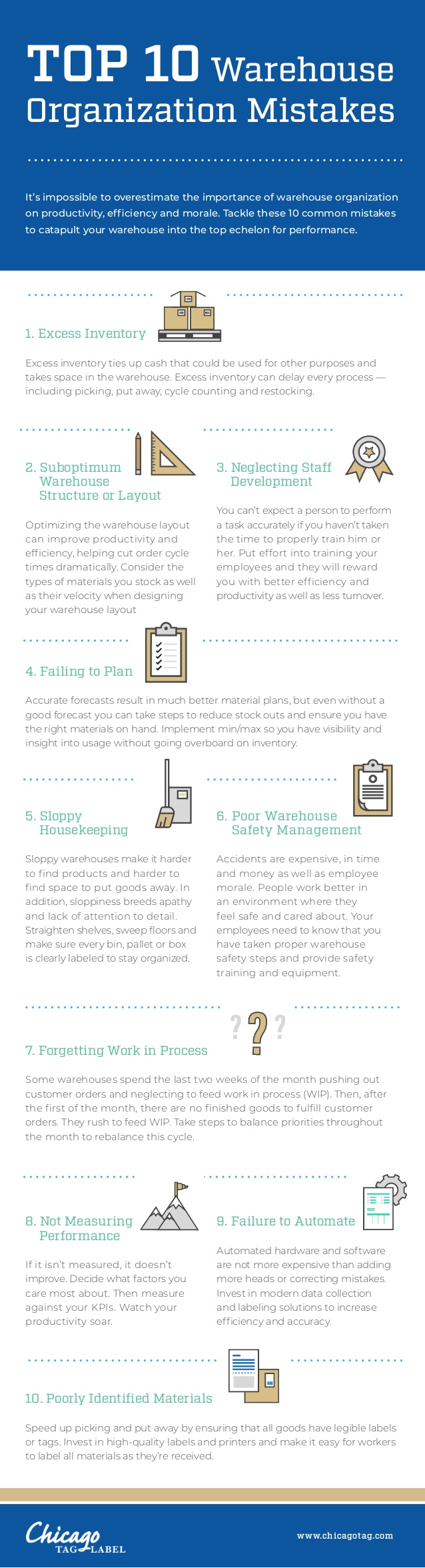

For example, a frequent misstep a manager can make is forgetting to prioritize staff development. Without the right training, workers could slip into bad habits or become frustrated — which may lead to excessive turnover rates. Another error taken by too many is failing to invest the time and effort into metrics.

Measuring how well your staff and facility perform provides you with a baseline for improvements. If you aren’t able to compare success rates, you’ll never know how much better you can or should be. Countless professionals in the industry also do too much manually. Automating certain tedious tasks such as label generation and data collection has the potential to make life much easier.

Don’t let any of these blunders turn your supply chain into a joyless experience. For more of these crucial mistakes and how to avoid them, see the below infographic: