Articles by Brenda Percy

Food safety: Don’t put your suppliers in a “silo”

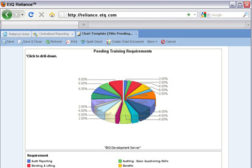

Cloud-based systems increase transparency & reduce risks

September 3, 2014

Advertisement

Do You Have a Crisis Management Plan in Place? 7 Reasons You Should

March 11, 2014

How do you manage Sustainability?

Enterprise software platforms track & analyze initiatives

June 6, 2012

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest safety trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing