OSHA’s HazCom/GHS, however, is not the only source for required employee training about precautions when dealing with chemicals. Another important source is the DOT Emergency Response Guidebook (ERG). Although the ERG does not provide globally harmonized precautions for chemical spills during transportation, the 2012ERG was jointly created by the U.S., Canada, Mexico, and Argentina. Therefore, the ERG has regional harmonization.

The ERG is updated about every four years and the 2012ERG is available now. See reference section on p.22 for link to free PDF of the 2012ERG. All public police, fire, and emergency responders are equipping their vehicles now with copies of the 2012ERG.

Who requires training on ERG?

OSHA’s Hazwoper standard requires at 1910.120(q)(6)(i)(E) that employers train first responders on the contents of the ERG. First responders include employees who may witness or respond to an emergency release of a chemical from its shipping or process container. If the employer’s Emergency Action Plan required at 1910.38 calls for all employees to evacuate the workplace in the event of an emergency release of a chemical, then training on the ERG is not required.

General duty training

Employees with safety, health, hazard communication, environmental, and security responsibilities should also be familiar with the ERG. For example, security personnel should be aware of the 2012ERG safe stand-off and evacuation distances from Improvised Explosive Devices (IED); such as a pipe bomb or even a small LPG tank e.g. outdoor grill size, used as an IED.

Sections 311 and 312 of the EPA’s Emergency Planning and Community Right-to-Know Act requires employers to provide Safety Data Sheets obtained or developed under OSHA HazCom to the local emergency planning committee and local fire department. If public responders are called to a workplace because of a chemical event, information in the SDS and 2012ERG will be reviewed to establish a course of action.

The green bordered pages within ERG2012 relate to extremely hazardous substances and may include accidental releases regulated under section 112(r) of the EPA’s Clean Air Act. Be aware that your worksite may be subject to EPA enforcement for an accidental release of a chemical even if threshold planning quantities are not exceeded for extremely hazardous substances.

It may appear to be a strange connection, but the EPA requires site evaluations under 112(r) to include conditions that are governed under OSHA’s General Duty Clause GDC. See link in reference section to EPA’s memorandum on using OSHA’s GDC. To learn more about OSHA’s GDC, link to ISHN July 2011 article “growing obligation to prevent harm.”

EPA’s application of the GDC allows the agency to hold employers responsible to:

1. Know hazards of chemicals and impact of possible release,

2. Design and maintain a safe facility to prevent a chemical release, and

3. Minimize consequence of an accidental chemical release.

The above are broad responsibilities. To help define and possibly limit these responsibilities, H.R. 6345 “General Duty Clause Clarification Act” was proposed on August 2, 2012 (see link at references).

Incidental v. emergency

Although ERG2012 contains a lot of useful information, the information is often misused. The misuse, which I have encountered with growing regularity over my years of involvement with workplace chemicals, is that we are becoming a nation that is overly cautious when dealing with chemical spills and chemical exposures. This overly cautious nature occurs for many reasons and is likely to expand following employee training of label element precautions in HazCom/GHS.

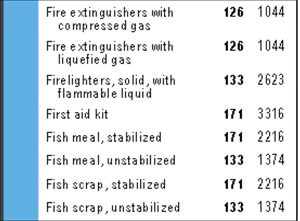

To illustrate how misuse of ERG2012 may occur, look at a clip on the right. The clip shows some DOT materials followed by their Guide and ID numbers. Consider the first aid kit. If there is a spill from a first aid kit, how far should people be evacuated from the spill or leak area to keep them safe?

If there are liquids involved with the kit, Guide 171 says, “As an immediate precautionary measure, isolate spill or leak area in all directions for at least 150 feet.” That distance is more than 1 ½ times the length of a basketball court. And recommendations for response clothing include use of an SCBA.

Guide 171 and precautionary distances also applies to a spill of stabilized fish scrap. If the fish scrap is unstabilized, or if the spill involves “Hay, wet, damp or contaminated with oil” found elsewhere in the 2012ERG, follow Guide 133 where the precautionary distance is only 75 feet. Guide 133, however, also recommends use of an SCBA.

Under some conditions, chemicals that may be in a first aid kit such as alcohol, iodine, and hydrogen peroxide may cause harm if spilled. Quantity of the chemicals is an important condition. Fish scrap and wet hay may spontaneously ignite, if conditions allow. Time and quantity are important conditions before fish scrap and wet hay may cause harm.

Just a guide

Determining whether harm is probable from a chemical spill or exposure involves numerous factors. The 2012ERG is just what it is called … a guide. It is not meant to be followed without using professional judgment.

Likewise, use of precautionary statements in HazCom/GHS must not be followed without question. For example, if a precautionary response statement says “Call a poison center/doctor if you feel unwell” the response must be supported by input of professional judgment.

An overly cautious response to chemical spills or exposures, as noted in many recent news reports, does not serve employers or employees well in the evolving era of “right-to-understand” about chemicals. Guides found in 2012ERG, HazCom/GHS or within the broad world of OSHA GDC must be tempered with professional judgment.

To address an over-response to guides all, EHS pros should continually expand their understanding of how and when a chemical may cause harm — and when the chemical is unlikely to cause harm.

References:

1. Obtain DOT 2012 ERG at http://phmsa.dot.gov/staticfiles/PHMSA/DownloadableFiles/Files/Hazmat/ERG2012.pdf

2. ISHN July 2011, “A Growing Obligation to Prevent Harm” at http://www.ishn.com/articles/print/91333-a-growing-obligation-to-prevent-harm

3. EPA memorandum to use OSHA GDC at http://www.epa.gov/oecaerth/resources/policies/monitoring/caa/caa112rmemo.pdf

4. H.R. 6345 “General Duty Clause Clarification Act” issued on August 2, 2012 http://www.gpo.gov/fdsys/pkg/BILLS-112hr6345ih/pdf/BILLS-112hr6345ih.pdf