From a spill control material manufacturing perspective, we often assumed that the lion’s share of front-line outdoor workers receives some type of oil/fuel spill control training prior to being exposed to a spill. After all, environmental risks are higher in the outdoors, and front-line workers typically encounter the initial spill.

Contrary to this belief, extensive field work with hundreds of customers across various outdoor industries has revealed that in many cases, individuals with the least amount of training are first to encounter oil spills. Often, it is only after the emergency has been identified and called in, that the environmental coordinators, qualified emergency responders or experienced spill control professionals become involved.

But why should you invest in preparing front-line workers for oil and fuel spills in the outdoors?

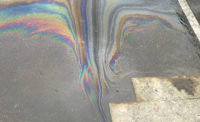

As with other EHS issues, an oil-based leak, drip, or spill in the outdoors evokes serious potential consequences. Whether the release is large or small, environmental contamination is a major issue.

As a result of environmental damage, the responsible party may face fines, decontamination and remediation fees, and negative publicity. Moreover, oil spills can be harmful to the health and safety of your employees.

Now, what if we told you that preparing a proactive front-line approach to oil spills could help reduce your overall risk, preventing a minor spill from becoming a major EHS catastrophe?

Helpful hints for a proactive front-line approach

In our field work, we’ve encountered three primary elements to establishing a successful front-line approach, namely:

- Appropriate spill kit Contents

- Suitable spill kit Location

- Relevant spill kit Training

While getting one or two of these elements correct is helpful, we’ve observed that it’s nearly impossible to have a well-rounded approach without properly addressing all three of these elements.

Spill kit contents

To get started, we highly recommend that you review existing incident reports to search for patterns. During this process, organize your thoughts by building out a checklist. Among other things, be sure to ask yourself:

- What is the primary goal of my front-line workers (e.g. will they be trained to clean up the spill or to safely contain the spill until environmental professionals arrive)?

- How large is a typical leak, drip, or spill, and how much absorption capacity is required of my kit(s)?

- If you are in a fixed location, and are you equipped to protect your highest risk areas (soil, groundwater, or waterways)? Or if you are mobile, to which high risk areas might you be exposed and are you equipped to protect them?

- Are your spill control materials effective for oil leaks, drips, and spills regardless of weather conditions, rain or shine?

- Are your spill control materials ergonomically friendly, so that they can be deployed with speed and ease?

Remember, not all spill control materials are created equally. Your spill kits should be outfitted to match your needs. We've observed that up to 80 percent of the spills in the outdoors are hydrocarbon based (hydraulic oils, diesel fuel, motor oils, transmission fluids, etc.). And your spill control materials should be effective in wet weather as well as dry. Above all, they should be compact and lightweight for rapid deployment to mitigate the risk of environmental damage.

Spill kit location

Another issue we’ve seen time and time again is that spill kits are kept in an unsuitable location. When immovable 95-gallon overpack spill kits are left in isolated areas, workers will waste an excessive amount of time and energy to deploy the spill control or containment materials to the spill site. Here is what you may want to consider:

- Where do the majority of my spills occur?

- Where are my current spill kits located?

- Is my kit mobile? If yes, how quickly can I mobilize my kit to the spill site? If no, how quickly can the kit be emptied and contents deployed?

Spill kit training

In order to successfully train your front-line workers, you must to identify who those individuals are. It will be essential to ask yourself:

- Where do oil and fuel spills occur?

- What job functions are most likely observe or be exposed to oil spill incidents?

- What is expected of my front-line workers (e.g. will they be trained to clean up the spill or to simply contain the spill until environmental professionals arrive)?

Conclusion

In 2017 the demand to embrace social responsibility as stewards of the environment and of our employees is a necessity. These helpful hints and guidelines don’t fully encompass the complexities oil spill compliance, nor are they meant to do so. Rather, the goal of this article is to encourage readers to consider the adoption of a more proactive front-line approach to oil spill control in an effort to better protect the environment and front-line workers. For further resources, please refer to the footnotes section or contact the author directly.

Resources

1. In 2016, 6,478 oil-based spills* were reported to the National Response Council (NRC). Of these, 5,979 spills were classified as either reaching or not reaching a body of water (in 503 cases, this data was not recorded). Of the 5,975 recorded cases, 4,315, or 72% of the spills were reported to have reached a body of water, while only 1,660 cases or roughly 28% were reported to have not reached a body of water. With 72% of these oil spills reaching a body of water, there is obviously much room for improvement in this regard. *Oil spills in this context refer to CHRIS Codes: ODS, OFR, OHY, OIL, OLB, OMN, OMT, OOD, OON, ORS, OSX, OTB, OTD, OTF, OTH, OTW, OUN, OWA. See stats here: http://nrc.uscg.mil/

2. In 2016, the NRC statistics reflect that in oil based spills, only 31% occurred during “clear” (25%) and “sunny” (6%) conditions, while 39% occurred under “overcast” (20%) and “rainy” (19%) conditions. The other 30% of oil spills occurred when grouping the remaining conditions of “foggy” (2%), “other” (1%), “partly cloudy”(23%), “snowy” (3%), and “sleeting” (0%). Oil spills in this context refer to CHRIS Codes: ODS, OFR, OHY, OIL, OLB, OMN, OMT, OOD, OON, ORS, OSX, OTB, OTD, OTF, OTH, OTW, OUN, OWA. See stats here: http://nrc.uscg.mil/

3. Got questions? Visit the EPA Oil Spills Prevention and Preparedness Regulations Website, here: https://www.epa.gov/oil-spills-prevention-and-preparedness-regulations