The proper storage of materials is a key factor in keeping your business operating efficiently and generating profits. Just as important is the safety aspect of keeping your stored materials from injuring your employees.

Storing materials can be done in different ways and can include general storage and flammable storage.

General storage

Companies store materials in various ways. But no matter how they’re stored, you must make sure these materials don’t create a hazard for employees.

There are ways to prevent hazards when storing materials, including the most basic one of all — keeping storage areas free from accumulated materials that:

- Cause tripping, fires, or explosions; or

- Contribute to the harboring of rats and other pests.

- It’s important your employees protect themselves by knowing:

- The stored material’s height and weight,

- How accessible the stored materials are, and

- The condition of the containers that are holding the materials.

Falling materials and collapsing loads can crush or pin employees, causing injuries or worse. Make sure your employees follow OSHA’s safety guidelines when stacking materials, including:

- Stack lumber no more than 16 feet high if it is handled manually, and no more than 20 feet if using a forklift;

- Remove all nails from used lumber before stacking;

- Stack and level lumber on solidly supported bracing;

- Ensure that stacks are stable and self-supporting;

- Don’t store pipes and bars in racks that face main aisles to avoid creating a hazard to passersby when removing supplies;

- Stack bags and bundles in interlocking rows to keep them secure; and

- Stack bagged material by stepping back the layers and cross keying the bags at least every ten layers.

Additional OSHA guidance states:

- Store baled paper and rags inside a building no closer than 18 inches to the walls, partitions, or sprinkler heads;

- Band boxed materials or secure them with cross-ties or shrink wrap;

- Stack drums, barrels, and kegs symmetrically;

- Block the bottom tiers of drums, barrels, and kegs to keep them from rolling if stored on their sides;

- Place planks, sheets of plywood dunnage, or pallets between each tier of drums, barrels, and kegs to make a firm, flat, stacking surface when stacking on end;

- Chock the bottom tier of drums, barrels, and kegs on each side to prevent shifting in either direction when stacking two or more tiers high; and

- Stack and block poles as well as structural steel, bar stock, and other cylindrical materials to prevent spreading or tilting unless they are in racks.

Flammable storage

Many locations have flammable liquids and they must be stored properly to be OSHA compliant. Flammable liquids are divided into four categories as follows:

1910.106(a)(19)(i) says category 1 flammable liquids have flashpoints below 73.4 °F (23 °C) and a boiling point at or below 95 °F (35 °C);

1910.106(a)(19)(ii) says category 2 flammable liquids have flashpoints below 73.4 °F (23 °C) and a boiling point above 95 °F (35 °C);

1910.106(a)(19)(iii) says category 3 flammable liquids have flashpoints at or above 73.4 °F (23 °C) and at or below 140 °F (60 °C). When a category 3 liquid with a flashpoint at or above 100 °F (37.8 °C) is heated for use to within 30 °F (16.7 °C) of its flashpoint, it shall be handled in accordance with the requirements for a category 3 liquid with a flashpoint below 100 °F (37.8 °C); and

1910.106(a)(19)(iv) says category 4 flammable liquids have flashpoints above 140 °F (60 °C) and at or below 199.4 °F (93 °C). When a category 4 flammable liquid is heated for use to within 30 °F (16.7 °C) of its flashpoint, it shall be handled in accordance with the requirements for a category 3 liquid with a flashpoint at or above 100 °F (37.8 °C).

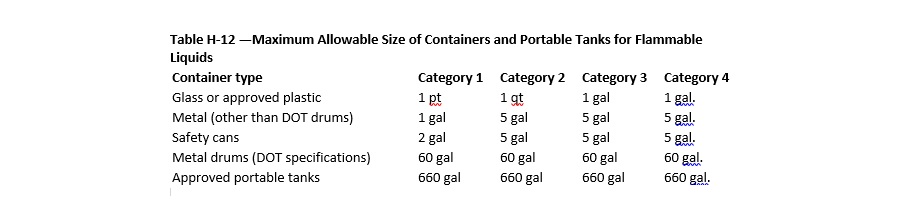

OSHA says only approved containers and portable tanks can be used. Generally, flammable liquid containers must be sized according to Table H-12.

Metal cabinets commonly called “yellow fire cabinets” are often used to store flammable liquids. These have certain design requirements:

- The bottom, top, door, and sides of metal cabinets must be at least number 18-gauge sheet iron and double walled with 1 ½ - inch air space;

- Joints must be riveted, welded, or made tight by some equally effective means;

- The door must be provided with a three-point lock; and

- The doorsill must be raised at least two inches above the bottom of the cabinet.

Flammable liquids can be stored in other places — flammable storage warehouses, inside storage rooms, and outside of buildings.

In industrial plants, OSHA allows incidental storage of flammable liquids where the use and handling is incidental to the principal business.

OSHA provides specific guidance on incidental storage quantities. Here’s how it works:

- Flammable liquids need to be stored in tanks or closed containers.

- The quantity of liquid that may be located outside of an inside storage room, storage cabinet in a building, or in any one fire area of a building cannot exceed:

- 25 gallons of category 1 flammable liquids in containers;

- 120 gallons of category 2, 3, or 4 flammable liquids in containers; and

- 660 gallons of category 2, 3, or 4 flammable liquids in a single portable tank.

Areas where flammable liquids are transferred from one tank or container, to another container, must be separated from other operations in the building by adequate distance or by construction having adequate fire resistance.

Your incidental storage areas have certain requirements you need to follow to protect your facility and your employees. This includes providing:

- Drainage to control spills, and

- Adequate natural or mechanical ventilation.

Remember, adequate aisles must be maintained for the unobstructed movement of personnel and so that fire protection equipment can be positioned as needed. This would also be true for any area where flammable liquids are being used and stored.

Wrap-up

Properly storing materials is critical in keeping your business running efficiently and protecting your employees. Don’t let OSHA catch you with your guard down.