Chemical exposure and management is a paramount concern for EHS industry leaders. But let’s be honest. Safety data sheet (SDS) information is not always clear about the hazards represented by a material or its ingredients. How do EHS leaders identify problematic documents and acquire the information necessary for effective decision-making about the materials on site, exposure and worker protection?

The solution to these challenges requires workplaces to evaluate the impact of the Globally Harmonized System (GHS) on their SDSs, identify data gaps and work with vendors to ensure they are providing the right information for safe and efficient workplaces.

The disharmonization of GHS: what happened?

The GHS is intended to unify hazard communication and visibility across international borders. However, its varied adoption yields problematic challenges when pictograms, classifications, exposure limits and hazard and precautionary statements do not align among agencies for the same material. Not only do elements not align, but many GHS Safety Data Sheets lack critical information necessary for EHS professionals to make effective decisions regarding hazard communication, regulatory compliance and safety procedures.

Consider that regulations are not always specific. For example, Part 1910.1200(d)(1): “Chemical manufacturers and importers shall evaluate chemicals produced in their workplaces or imported by them to classify the chemicals in accordance with this section. For each chemical, the chemical manufacturer or importer shall determine the hazard classes, and, where appropriate, the category of each class that apply to the chemical being classified. Employers are not required to classify chemicals unless they choose not to rely on the classification performed by the chemical manufacturer or importer for the chemical to satisfy this requirement.” (OSHA, 2012)

Hazards are not always clearly represented on an SDS. Employers must decide whether to put worker protection over using possibly incorrect or incomplete data. Careful review of the SDS is crucial to provide the best protection possible. This example is just a glimpse of the challenges faced when organizations determine how to produce and manage accurate SDS data. Vendors and clients alike have worked diligently to connect the dots of GHS. Supply chains across multiple jurisdictions encounter even more challenges to compliance—variations between each jurisdiction’s implementation of GHS combined with multiple languages or regulatory bodies illuminate the complexity of managing pertinent information. At first glance of an SDS, the 16-section format may seem orderly and fully inclusive of key components that are required for compliance. However, the devil is in the details.

What to look for

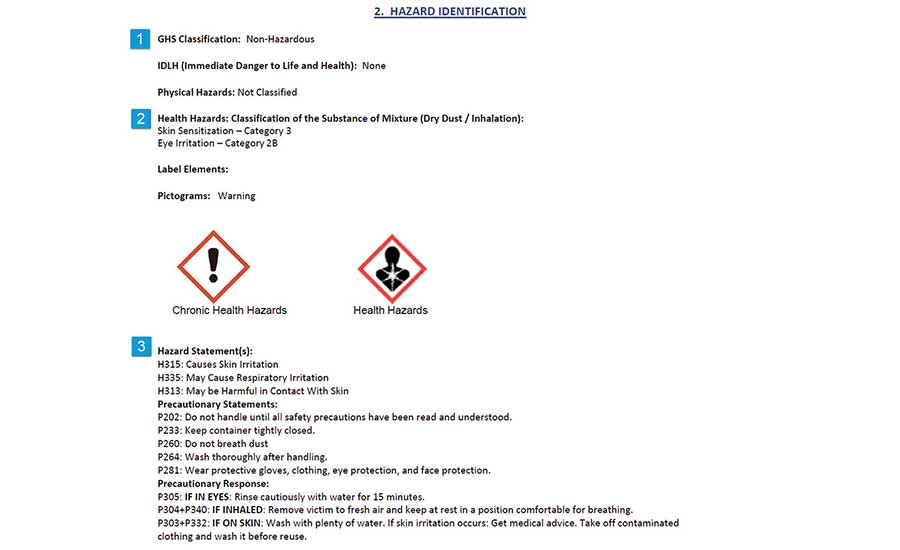

Looking at Section 2 of this SDS, hazard identification is baffling. In Figure 1, this SDS states that the GHS Classification for this material is “Non-Hazardous.” (1) However, the document clearly displays two pictograms with captions that indicate that there are Health Hazards. (2) The same section notes Health Hazards - Skin Sensitization, Category 3. There is no Category 3 for Skin Sensitization under GHS. So, how should workers handle this material? And what information should employers provide?

Many EHS workers rely on pictograms found on SDSs or labels to quickly understand a material’s hazards. The Health Hazard pictogram in this example is displayed without a classification listed in the Health Hazards above, which is confusing. That is, until you continue to read through the Hazard Statements (3) and find H335: May Cause Respiratory Irritation listed. Is that why the Health Hazard pictogram was used? Before moving too much further, you’ve probably noticed that there isn’t a Hazard Statement to go with the Health Hazard Classification, Eye Irritation – Category 2B. Or if you read the Hazard Statement H315: Causes Skin Irritation but the classification states Skin Sensitization. Which is it?

At this point it’s probably a good time to call the vendor (if you haven’t already). Health Hazard Classifications, Pictograms, Hazard and Precautionary Statements work hand in hand. If there is a Hazard Classification, there should be a Hazard Statement and so forth. If there are gaps, a deeper look and communication with your vendor may be in order. Below are two foundational pieces of information that must be clarified with your vendors to maintain compliance and proper safety procedures within your organization.

What agency is represented on the SDS?

GHS does not require manufacturers and distributors to include foundational information on SDSs, such as the agency for which that document is written. However, this is the primary indicator for the information you see in a document. Employers must be aware of which agency’s criteria is utilized when classification information such as Pictograms and Hazard Phrases are applied on the SDS. Employers are often left to search for clues on the SDS to establish its correlated agency.

What exposure limits are applicable to the material?

There are various paths to arriving at the Exposure Limit listed on an SDS. Vendors may choose to follow OSHA 29 CFR 1910.1000 HCS or may choose a different resource. It is common industry consensus that the OSHA PELs are outdated and the more relevant exposure limits (ACGIH, NIOSH, etc.) should be included on the SDS in addition to the required OSHA PELs. However, not all vendors choose to include the more protective exposure limits. For that reason, it is critical that employers know this information so they can make adjustments if the limits on the SDS are not conservative enough for internal EHS protocols. Asking vendors to note the standard used improves clarity, safety and the bottom line. For vendors, including this information on SDSs is a simple and easy way to support EHS activities and provide employers a visible SDS sanity check.