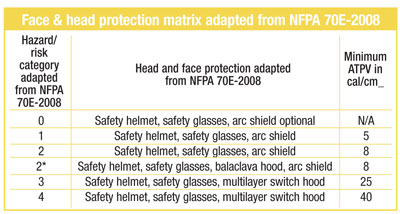

The National Fire Protection Association’s standard 70E-2008 establishes hazard or risk categories as shown in the table below. Included are electric arc-shields suitable for use in hazard/risk categories 1, 2, 3 and 4. The minimum arc thermal performance value (ATPV) is listed below (cal/cm2 stands for calories per square centimeter):

An electric arc shield provides protection in two ways: by limiting the heat and light transmission of the shield material and by redirecting the heat blast. The arc shield is composed of a primary material (i.e. polycarbonate) with absorbers added that have heat-absorbing properties to prevent penetration. A properly designed shield should be sufficient in size with a wraparound design to shield the worker’s face.

Note that arc shield ratings typically come standard at 8, 10, 12 and 40 cal/cm2 ratings. Shields rated 10 or 12 cal/cm2 are typically provided with a chin protector for added protection. For the highest rated 40 cal-rated shields, dual shields are a common design solution used in conjunction with multilayered hoods.

Each HRC category requires an ANSI Z89 Class E (20,000 volt) rated safety cap to be worn by workers. The arc shield is attached to the safety helmet using a visor bracket/carrier. The visor bracket needs to adapt snugly to the slope and length of the helmet brim to avoid gaps between the bracket and helmet.

As there is no industry standard for helmet slots, each brand has its own width and depth, so attention is required to get a firm fit. As the shields with chin protectors are heavier, the visor bracket should be designed with a strong spring in order to hold the arc shield in the up position to avoid flopping in front of a worker’s face. In addition arc shields are provided with anti-fog coating.

In noisy environments it is common that the helmet be equipped with cap-mounted ear muffs to protect the worker’s hearing. Accessories like these should be tested for flammability and should be of dielectric construction.

Questions to consider

- Have the arc shield and accessories undergone test certification to ASTM 2178-08 by an independent certified laboratory?

- Is the visible light transmission high enough for workers to properly do their work? (60 to 70 percent is the industry standard.)

- Are workers wearing ANSI Z87+ certified safety glasses in addition to arc shields for impact protection (as required by the ANSI standard)?

- Are the materials of the shield made of a like polycarbonate to insure temperature resistance incold weather climates?