By John Snawder, Ph.D, DABT; Eric Esswein, MSPH, CIH; Bradley King, MPH, CIH; Michael Breitenstein, BS; Marissa Alexander-Scott, DVM, MS, MPH; Kyla Retzer, MPH; Max Kiefer, MS,CIH and Ryan Hill, MPH.

By John Snawder, Ph.D, DABT; Eric Esswein, MSPH, CIH; Bradley King, MPH, CIH; Michael Breitenstein, BS; Marissa Alexander-Scott, DVM, MS, MPH; Kyla Retzer, MPH; Max Kiefer, MS,CIH and Ryan Hill, MPH.

Although worker safety hazards in the oil and gas extraction industry are well known, there is very little published data regarding occupational health hazards (e.g., types and magnitude of risks for chemical exposures) during oil and gas extraction operations. To address the lack of information, NIOSH requests assistance from oil and gas stakeholders in further characterizing risks for chemical exposures during flowback operations and, as needed, develop and implement exposure controls. This blog briefly describes flowback operations and addresses reports made known to NIOSH of recent worker fatalities related to or located at flowback operations.

Worker Fatalities

NIOSH learned about several worker fatalities associated with flowback operations through media reports, officials with the Occupational Safety and Health Administration (OSHA), and members of the academic community. According to our information, at least four workers have died since 2010 from what appears to be acute chemical exposures during flowback operations at well sites in the Williston Basin (North Dakota and Montana). While not all of these investigations are complete, available information suggests that these cases involved workers who were gauging flowback or production tanks or involved in transferring flowback fluids at the well site. Often these fatalities occurred when the workers were performing their duties alone.

Potential Exposures during Flowback Operations

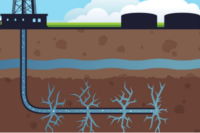

Flowback refers to process fluids from the wellbore that return to the surface and are collected after hydraulic fracturing is completed. In addition to the hydraulic fracturing fluids originally pumped, returned fluids contain volatile hydrocarbons from the formation. After separation, flowback fluids are typically stored temporarily in tanks (figure 1) or surface impoundments (lined pits, ponds) at the well site. Liquid hydrocarbons from the separation process are routed to production tanks (figure 2). Workers periodically gauge the fluid levels in flowback and production tanks with hand-held gauges (sticks and tapes) through access hatches located on the top of the tank.

Hydrogen sulfide (sour gas) is well recognized as a toxic exposure hazard associated with oil and gas extraction and production (1,2). However, less recognized by many employers and workers is that...Click here to read the rest of the post.