The Respiratory Protection Standard (1910.134)3 is one of OSHA’s top 10 most cited standards for fiscal year 2019, it is also ranked within the Top 10 “serious” violations4.

Employee exposure to airborne contaminates in the working environment and an insufficient respiratory program, or the lack of one, may result in OSHA violations and fines. It is essential as an employer to understand the importance of respiratory protection and when a Respiratory Protection Program (RPP) is needed.

When defining an action plan, it is best practice to have a Certified Industrial Hygienist2 perform an air quality test in the work environment. The hygienist will assess exposure and contaminant levels in the working environment to determine if levels fall within allowable exposure limits outlined by OSHA or other applicable government occupational limits. Once the air quality has been assessed the level of employee protection can be determined to provide a compliant work environment.

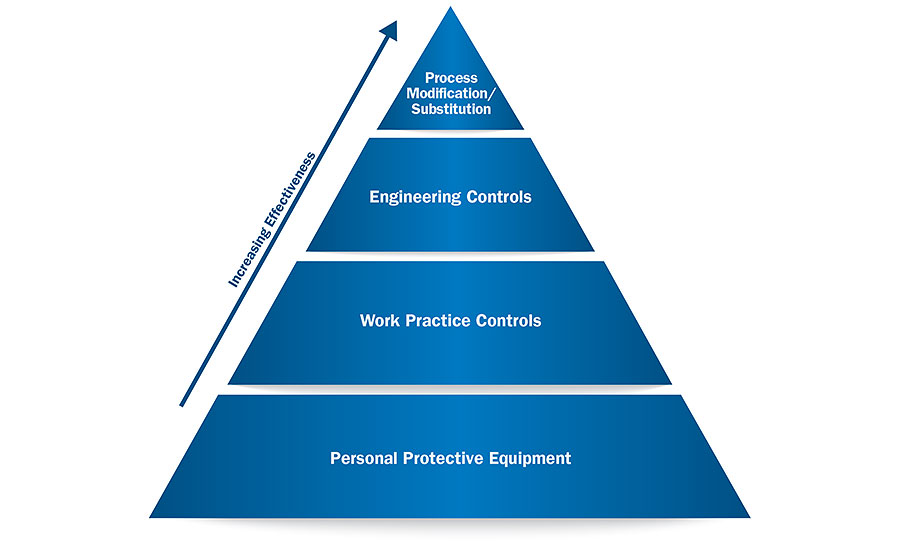

To provide a compliant working environment, OSHA has developed a Hierarchy of Controls to reduce airborne contaminants below their occupational exposure levels. When determining the action plan, start at the top and work your way down OSHA’s Hierarchy of Controls. It may be necessary to implement multiple controls, including an RPP, to be compliant and to achieve the desired results.

When is an RPP needed?

When process modification, engineering controls and work practice controls are not able to reduce employee exposure below permissible levels, respiratory protection should be implemented.

If respiratory protection is required, OSHA’s Respiratory Protection Standard (29 CFR 1910.134) requires employers to establish and maintain an effective RPP. 1

The primary objective of implementing an RPP is to maintain a compliant workspace for each employee and to prevent or limit exposure to airborne contaminants such as dusts, fogs, fumes, mists, gases, smokes and vapors2.

Different hazards require different respirators, and employees are responsible for wearing the appropriate respirator and complying with the RPP. The results of the air quality testing done by a Certified Industrial Hygienist in your environment will help determine what type of respirator is needed.

What is an RPP?

An RPP includes measures to ensure that all employees are maintaining compliance by outlining worksite-specific procedures for respirator use.

OSHA’s Respiratory Protection Standard requires that each RPP includes a written plan that details the administration of the program. In addition, the employer must be able to demonstrate that the program is enforced and updated as necessary.

The program must be supervised by a program administrator. It is the administrator’s responsibility to understand the respirator chosen to supervise the program appropriately. Larger plants or companies with industrial hygiene, in-house medical, safety engineering, or fire prevention departments should administer the program with the program administrator. 1

OSHA developed a small entity compliance guide5 to assist small businesses with compliance of the respiratory protection standard.

This guide does not alter or determine compliance responsibilities but provides a comprehensive step-by-step guide complete with checklists and commonly asked questions to aid small business employees and employers with a better understanding of OSHA’s respiratory protection standard. Additionally, OSHA maintains shorter documents and visual aids to better understand respiratory protection and the OSHA standard itself. This information can be found at www.osha.gov.

What’s in an effective RPP?

Employers must establish and maintain a written program consisting of policies and procedures that address respiratory protection elements including:1

- Written worksite specific procedures

- Program evaluation

- Selection of an appropriate respirator approved by the National Institute for Occupational Safety and Health (NIOSH)

- Training

- Fit testing

- Inspection, cleaning, maintenance, and storage

- Medical evaluations

- Work area surveillance

- Air quality standards

Program evaluation

The employer must enforce and update the program as necessary to ensure all users of the respirators are familiar with the enacted procedures and know how to use the respirators safely and properly. In addition, the employer needs to evaluate the effectiveness of the RPP regularly – and retest the workplace anytime there is a change to the worker, the process or the facility – and modify the program when necessary to reflect the evaluated results.

- https://www.osha.gov/Publications/osha3079.pdf

- To contact an Industrial Hygienist, visit www.aiha.org or call 703-849-888.

- https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.134

- https://www.safetyandhealthmagazine.com/articles/19087-oshas-top-10-most-cited-violations

- https://www.osha.gov/Publications/3384small-entity-for-respiratory-protection-standard-rev.pdf