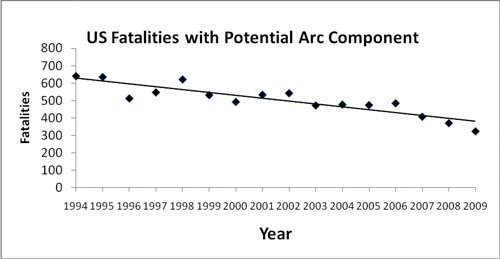

Electrical fatalities have declined in U.S. workplaces and around the world as companies have implemented OSHA 1910.269, National Electric Safety Code (NESC), and National Fire Protection Association (NFPA) 70E Electrical Safety in the Workplace (see chart below).

This decrease in fatalities is a good start, but the worker fatality rate still can be improved. Most accidents could be prevented with three changes in company work practices:

- Create an electrically safe work condition including lockout/tagout and verified testing by a qualified person.

- Use insulated gloves and/or sleeves when working parts energized or while testing and

- Use proper arc-rated clothing to prevent ignition and increase worker protection.

Many required pieces are in place to prevent all fatalities, but many of these aren’t clearly defined in OSHA law.

Standard shortcomings

Standards like NFPA 70E often are not required by state law and some states exclude chapter four of the NESC- the worker safety portion. Although OSHA will use these standards in abatement, some companies will ignore the standard if it is not law. Any smart company realizes that OSHA law is “performance-based” and that, when a worker is hurt, the employer is still liable. But some companies ignore standards, working to avoid any safety requirements unless they are the imaginary “OSHA minimum compliance.”

Another drawback of standards is that they are a compromise, since they are written by consensus and the committees have varying degrees of balance. The NESC 2007 and 2012 both require clothing that provides protection equal to the incident energy exposure but do not require any face protection. Addressing face protection in the NESC standard would be helpful. OSHA’s face protection requirement is clear but doesn’t apply to electric utilities, according to many attorneys.

29 CFR 1910.335(a)(1)(v) states, “Employees shall wear protective equipment for the eyes or face wherever there is danger of injury to the eyes or face from electric arcs or flashes or from flying objects resulting from electrical explosion.” This is the law, but NESC has no face protection requirements.

Define "flame resistant"

In 1994, there were no standards for flame-resistant clothing (often called FR or FRC, but arc-rated and flash fire rated are becoming more common to reduce confusion) for arc or flash fire. OSHA’s 1994 standard 1910.269 forced the hand of industry to finally adopt standards to define arc-rated clothing. ASTM F1506 first appeared in 1998 but didn’t contain an arc rating requirement until 2000 because a test method was not accepted by the committee. Only the firefighter’s standards for flame-resistant clothing existed, so people would pull old military standards like FTMS No. 191A Method 5903.1, Flame Resistance Cloth Vertical, which the military was no longer using, and cite them for clothing.

The problem with these standards was that they had not been updated. Out-of-date standards can be worse than no standards, because they give the “appearance” of compliance without giving any real information about the applicability of the test results. After a standard is developed, companies begin researching ways to introduce new materials which pass the standard, but if the standard does not keep up with the market developments, these new materials that pass may be dangerous. This is why it is so important for end users to be involved in the standards processes.

Until 2000, there were really no standards for “FR” clothing other than the firefighter clothing standards and the old military standards. In 2000, F1506 (which had been around since 1998) required arc ratings and NFPA 2112 required flash fire ratings. These requirements were the first full scale tests for real flame exposures. Many people do not know how earth-shattering this was. Now we can really test and even rate clothing protection for arc flash and flash fire.

So what is “FR” or flame resistant clothing? Flame resistant is defined by ASTM as “the property of a material whereby flaming combustion is prevented, terminated, or inhibited following application of a flaming or non-flaming source of ignition, with or without subsequent removal of the ignition source”(ASTM D123-07 Standard Terminology Relating to Textiles). This definition is generic and does not mean that if a material has these characteristics in any test it can be used for any purpose.

Specific standards are now in place for picking the appropriate clothing or PPE for most exposures. Table 1, below, includes the proper standards for different work situations. Using these standards will almost always secure the correct type of PPE for the exposure but the “authority having jurisdiction,” in NFPA parlance, is required to do due diligence in hazard assessment to assure that workers are not injured by hazards in the workplace. Marketers can be a great assistance in educating the specialists and even in writing the standards but marketers can also just “follow the herd” pushing an improper standard for applications it wasn’t intended for because of a vacuum in the appropriate standards.

In assessing hazards, engineering and administrative controls should be the first choice but, in electrical exposures, they are almost never adequate since implementing the controls themselves is a hazard in the case of voltage testing or shutting down equipment. Some PPE will almost always be required. Reading the NFPA 70E tables is very helpful in understanding how to balance hazard and risk but the tables do not work for larger industrial electrical systems in most cases. However many people confuse the NFPA 70E tables as prescriptive when they are actually only prescriptive when the company determines they will use the tables for their hazard and risk assessment. When the company chooses to do arc flash calculations and a risk assessment, many of the prescriptions in NFPA 70E are eliminated. In the market, many companies have issues with NFPA 70E, most of these issues are failure to do a proper risk assessment following arc flash calculations. The tables are hazard/risk tables. Arc flash calculations are only hazard assessment without the risk assessment. Adding the risk part to the hazard assessment of arc flash calculations eliminates many of the quandaries in NFPA 70E.

Don't be duped

Melting products are still masquerading as “flame resistant” because the market has no standard police and is just catching up with the changes in standards since 2000. This is usually part ignorance but we have found, in some cases, it is motivated by greed. When questioned, most of these deceptive companies tell me, “This is what the market wants.” They are wrong. The market wants cost-effective compliance, not deceptive practices.

Some uneducated purchasing folks and even some safety folks may be duped with look-alike or sound-alike or partial standards, but the market is catching on. Three large suppliers of ANSI 107 vests dropped “FR” from their 100-percent polyester offerings this year with the introduction of ANSI 107-2010. The ANSI committee under the much respected International Safety Equipment Association (ISEA) has chosen in the latest version of the standard to cite the proper standards.

Nylon, acrylic and polyester are good products for workers not exposed to flame, arc flash or thermal hazards but treating these melting materials with chemicals that help retard the flame in a small scale test like D6413 do not make them less hazardous as a flame and melting hazard in true flash fires or arc flashes. Small percentages of these melting materials have been successfully used in many truly arc rated or flash fire rated products but standalone they have never been truly flame resistant for clothing use. For a road worker exposed to flagging hazards and possibly even some low level heat exposures like a grinding machine or hot tar, this clothing could be adequate, but the safety officer doing the hazard assessment would need make this determination.

To portray these products as “FR” is a misnomer which the market cannot tolerate. Perhaps all melting materials (like polyethylene, polyester, nylon and acrylic) could receive these treatments when used in work clothing but companies should no longer call this clothing “FR”. We’ll see what the standards say, but today, these are not “FR” by any applicable standard for clothing. Keeping up with standards for the purpose of writing good clothing specifications is critical for safety. No one wants a worker to get hurt wearing something they thought was “FR”.

SIDEBAR: Electrical safety standards: Changes are coming

Compliance with OSHA electrical safety requirements using OSHA 1910.269 (the first arc flash regulation), NFPA 70E Electrical Safety in the Workplace (which added arc flash in 1995 and clothing in 2000) and National Electric Safety Code (NESC) (added arc flash requirements in 2007) has improved electrical safety statistics in the U.S. Changes are coming to all three electrical safety standards in 2012, but compliance with the current standards should not be delayed while waiting on the 2012 standards as they are really a tweak rather than an overhaul. The new NFPA 70E standard will likely have several new features (the final is typically available by September from NFPA or earlier from www.necplus.org) including:

- DC Task tables for stationary batteries and a new DC arc flash calculation Annex.

- Update of the task tables, an upgrade of HRC 2 to include use of a balaclava and some increases in protection requirements. The “notes” will also be built directly into the tables, thus eliminating the common misunderstanding of the tables.

- Requirement to use hoods when calculated exposures exceed 12 cal/cm².

- Requirements for specific thickness of leather gloves due to a delay in a glove standard from ASTM (the old requirement for weight of gloves was not available from manufacturers). Arc rated gloves should be acceptable when the ASTM standard is available.

- Additional guidance on labeling equipment with a new non-mandatory Annex.

- Additional guidance on risk assessment when performing arc flash calculations.

The new NESC and OSHA standards are expected mirror one another with both requiring arc flash calculations for utilities on secondary electrical systems (previously this only required higher voltage calculations) and other new requirements.

While tweaks occur throughout the standards, the important parts are virtually unchanged. Canada has similar standards in CSA Z462 and CAN/UL S801 respectively, and many countries have been adopting NFPA 70E, including Brazil, Chile, Peru and South Africa.