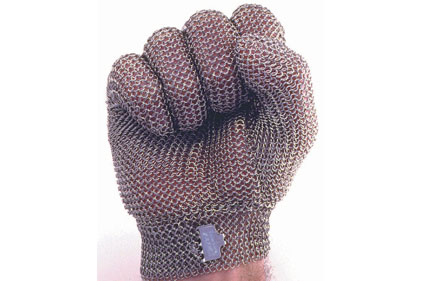

Leap forward 1,500 years. Metal mesh gloves have been modernized, but at their root are still woven together with thousands of individually formed metal rings. In the 1980s almost all manufacturers of mesh gloves switched to stainless steel.

Who uses mesh gloves and when?

Industries including textile cutting and sheet metal use metal mesh gloves for cut protection. The most popular user remains food processing, where anyone who uses a hand knife or cleans/moves a slicer blade can (should) wear a metal mesh glove.

It’s important to note even metal mesh gloves are neither cut-proof nor puncture-proof. They are cut- and puncture-resistant. But no glove is 100-percent cut-proof. Mesh gloves are only designed to be used around hand knives, not powered blades or saws with serrated edges. Warnings on packaging from almost all manufacturers read something like:

“WARNING: These gloves will not withstand the force of power-driven blades, saws, and tools; avoid this hazard.”

“WARNING: These gloves could be caught in moving machinery and should not be used where such contact is possible.”

What does the law state about mesh gloves?

There is no OSHA standard or regulation that requires metal mesh gloves to be used in any specific industry or application. However, OSHA has published the reference document OSHA 3108, “Safety and Health Guide for the Meatpacking Industry.” It can be accessed online at http://www.osha.gov/Publications/OSHA3108/osha3108.html.

In the section, “Protective Clothing and Equipment,” the last sentence of the first paragraph reads: “In addition, workers who use knives must be provided with metal mesh gloves and aprons, and wrist and forearm guards to protect them from knife cuts.”

How to tell one mesh glove from another?

Currently, there is no U.S. federal or state government standard about how to make a mesh glove. Several of the leading mesh glove manufacturers follow the European standard EN1082, and apply the CE mark as evidence of certified compliance. This standard covers several performance and design criteria, including ring weld (tensile) strength and ring assembly.

The tensile strength requirement, section 4.3.1 states that: “When tested…no ring, link or plate shall break open when a force of 100N is applied.” (An “N” is a Newton, a measure of force. 1 N is roughly 0.22481 pounds of force. So 100N, the minimum requirement, is roughly 22.481 pounds of force.)

Additionally, section 4.2.1 states that: “Chain mail….shall have 4 rings passing through each ring.” Again, because there is no standard in the U.S. for mesh gloves, some mesh glove manufacturers only connect their pieces of mesh using one ring and not four. As a result, the gaps at a glove’s seams are as large as 6.3mm, allowing enough room for a knife point to protrude.

The gloves produced by leading mesh glove manufacturers are assembled by weaving the joining ring around (over and under) at least four adjacent rings, in exactly the same way as the basic mesh material is interlocked. As a result, the seams are as strong, safe and secure as any other part of the glove, and the maximum gap is less than 3.1mm.

To be sure mesh gloves are the safest possible, check that they are compliant with EN1082.

Hygienic concerns

In most cases mesh gloves are worn in a slaughterhouse, food processing or food service environment, a kitchen cut-up or grocery — all locations where they contact food.

In each of these environments almost all of the tools and knives used are stainless steel. So are many of the surface materials, transport bins, etc. Why? Because stainless steel is a non-porous material that is relatively simple to clean and will not harbor bacteria.

However, original metal mesh gloves had a fabric strap around the wrist to close the glove around the hand. With a fabric strap you introduce a porous material to a purportedly hygienic environment. Fabric straps are challenging to clean, and they can be a place for bacteria to hide and grow — even after the most thorough cleaning processes.

As a result, a new generation of metal mesh gloves was developed without fabric straps. Eliminate fabric straps and you can reduce the risk of bacteria and cross contamination. Advanced metal mesh gloves can fasten around the wearer’s wrist without a fabric strap using a variety of stainless steel closing systems, including adjustable hook designs. This helps facilities comply with the USDA FSIS (Food Safety and Inspection Service) which states: “All plants must develop, adopt and implement a HACCP (Hazard Analysis and Critical Control Point) plan for each of their processes.” Plus, FSIS, in its Standard Operating Procedures for Sanitation states: “All plants must prepare and implement plant-specific standard operating procedures (SOPs) for sanitation to ensure they are meeting their responsibility to keep their facilities and equipment clean.”

Should you wear a metal mesh glove?

Think about your task and its hazards. Are you using hand knives? Are you cutting up food?

Initially the cost may seem prohibitive. Wrist-length gloves can cost approximately $100 each. But that expense should be compared to the costs that can be saved.

According to a 2005 report from the U.S. Bureau of Labor Statistics, 25 percent of all injuries resulting in days away from work were hand-related. The average cost per reportable hand injuries is $4,200, according to the National Safety Council. BLS data puts the cost of hand injuries at $8,500 for combined medical and indemnity costs. (This includes everything from a couple of stitches to severed tendons.) Even more alarming: 70 percent of workers suffering hand injuries were not wearing gloves. For the remaining 30 percent, injuries occurred because the gloves used were either inadequate or worn out.

In the food service industry, in 2005 OSHA estimated hand injuries cost about $300 million a year in medical costs, lost time from work and workers’ compensation payouts. In 2003, nearly 24,000 restaurant workers lost at least a day of work because of a cut, burn or scald, predominantly to the hands, according to the BLS.