ANSI eyewash and shower compliance are standard measures to abide by, but is it enough for your employees? There are several best practices that can and should be implemented to exceed the standard expectations and guarantee a reliable safety response.

The International Safety Equipment Association (ISEA) produces the American National Standard for Emergency Eyewash and Shower Equipment, ANSI Z358.1, to establish uniform minimum performance and use requirements. Still, additional steps and best practices can be implemented to exceed standard expectations and minimize injuries.

Critical issues: ANSI compliance & victim comfort

A recent safety industry survey asked professionals who make product recommendation and/or buying decisions what they considered the most important features and benefits when selecting an eyewash and/or eyewash/shower combination unit. Not surprisingly, the top two answers were ANSI compliance and victim comfort.

Victim comfort is an important consideration that should be factored into creating a complete safety response environment for your employees. Treat the purchasing process as if you could be the victim. This is key to finding the best product. From color coding equipment and establishing appropriate water temperatures to routine testing and ongoing training, consider these best practices for total victim comfort:

1. Accurate color coding

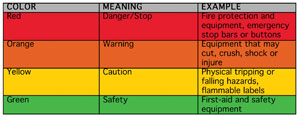

ANSI Z358.1 specifically states that locations of eyewashes and showers must be clearly identified, but it does not specify signage design. For workplace safety, OSHA requires that hazards be marked to alert employees of potential danger. ANSI Z535.1 takes this one step further, providing a standard for color schemes, sizing, meaning and application for various workplace hazards. The standard is intended to provide uniformity across various organizations and industries by helping employees identify the severity of a given hazard in the workplace. Oftentimes, an emergency station is not clearly marked, causing the victim to frantically locate an improper form of flushing such as a sink. Reference the color code chart below to consistently mark physical hazards around your facility:

Consistently using the familiar color for emergency signage can minimize unnecessary confusion in an urgent crisis situation, especially if the injured party has contaminants in or around their eyes.

2. Beyond tepid

Excessively hot or cold water temperatures in safety showers and eyewashes can exacerbate the very injuries this safety equipment is designed to reduce. In the 2009 revision of ANSI Z358.1, the standard outlines suitable water temperatures as tepid, defined as a range between 60? and 100?F (15.5? to 37.77?C). It also specifies a full 15-minute drench or irrigation cycle, a length of time that must be considered with the victim in mind.

Understanding that average water temperatures in a residential shower generally hover around 105?F (40.5?C) and room temperatures are considered comfortable between 68-70?F (20-21.1?C), a shower or eyewash running temperatures in the lower ANSI-required range fails to factor for victim comfort. Selecting a thermostatic mixing valve that offers protection against temperature spikes is an ideal solution to providing reliable temperature controls. A paraffin-base thermal actuation will keep outlet temperature within tight specifications to prevent scalding and hypothermia. In addition, a funnel design in the mixing chamber generates turbulent flow to ensure consistent temperature blending across the entire flow range.

By selecting a suitable mixing valve and defining a tepid water range that is more comfortable to the user, you are not only encouraging the full flush period but also increasing the likelihood that a victim will remove contaminated clothing, which further enhances the wash objective.

3. Facility activity impact

ANSI states that all eye/face washes, showers and combination units must be free of obstructions for the victim, but there are other factors to consider. Daily tasks that do not present a permanent obstacle can still have a large impact on the functionality of a safety unit. For example, a forklift driven through the facility may have indirect access to water pipes. Consider the repercussions that a small nick from one of the forks might have, or even worse, the damage that could occur to pipes unintentionally run over. Monitor and evaluate all accessible components of your facility’s safety units on a frequent and routine basis.

Keep facility impact considerations in mind during the site selection process for your safety equipment, and choose an area that is both readily accessible and highly usable during activation. Safety shower and eyewash equipment should meet appropriate standards for their distance from potential hazards, and they should be in areas with adequate space for emergency responder activities. A narrow area could potentially hamper accessibility and increase response time — a dangerous risk to take in an emergency situation.

4. Coordinating and documenting ongoing testing

Weekly activation is clearly stated in the ANSI standard as a necessary requirement to ensure proper operation of all emergency equipment. More extensive and detailed activation and inspection is required on an annual basis.

A common question relates to the appropriate length of time for unit testing. While a quick activation to test the unit might seem sufficient, it is more valuable to test each unit for the required 15-minute flush every time. The intention behind routine testing is to guarantee that each piece of equipment has the proper flushing fluid supply and flow, to clear the line of any sediment build-up and to minimize contamination related to inactive water. Testing should replicate a real-life scenario to ensure that each site can be confident in the emergency unit’s ability to reliably perform.

Documentation of the routine testing including location, dates and performance provides records to demonstrate your facility’s diligence in protecting and monitoring each unit. These records can be managed in a variety of forms, including inspection tags on the units and safety equipment surveys. Proper coordination of testing alleviates any questions or concerns related to functionality and allows your safety team an instant reference for monitoring all safety equipment performance.

5. Employee training and updates

Individual emergency scenarios rarely receive the same level of education and training as fire drills. A bad situation could quickly become worse if an injured employee does not know where to go, how to operate safety equipment, how long to operate the unit, or is unfamiliar with the proper procedure for a thorough flush. Trying to educate someone in the heat of the moment only creates confusion, heightening stress levels and creating an environment for mistakes and potentially increased injury. Build workplace familiarity with emergency equipment through regular training and employee drills. Educate all personnel so they can be their own best advocates in an emergency and, just as importantly, be a reliable resource for others. Safety is everyone’s responsibility.

Additional best practices

• Use bowl covers and inline strainers to keep bowls clean and flushing fluid debris-free, further reducing the odds of aggravating a victim’s injury.

• Repair and update non-compliant components. Remember, there is no grandfather clause with ANSI standards.

• Privacy for a victim shouldn’t be an afterthought. Providing privacy curtains or enclosed booths allows victims to comfortably remove contaminated clothing in a non-public setting.

While meeting ANSI standards is a necessity for workplace safety, following best practices to create a comprehensive safety response environment takes those standards one step further. It’s something from which all employees can benefit.