Home » robotics

Articles Tagged with ''robotics''

Keeping safety at the forefront as automation increases and labor shortages continue

Read More

Safety requires enabling robots and employees to work in harmony

Upkeep is only one part of industrial robotic maintenance

December 1, 2022

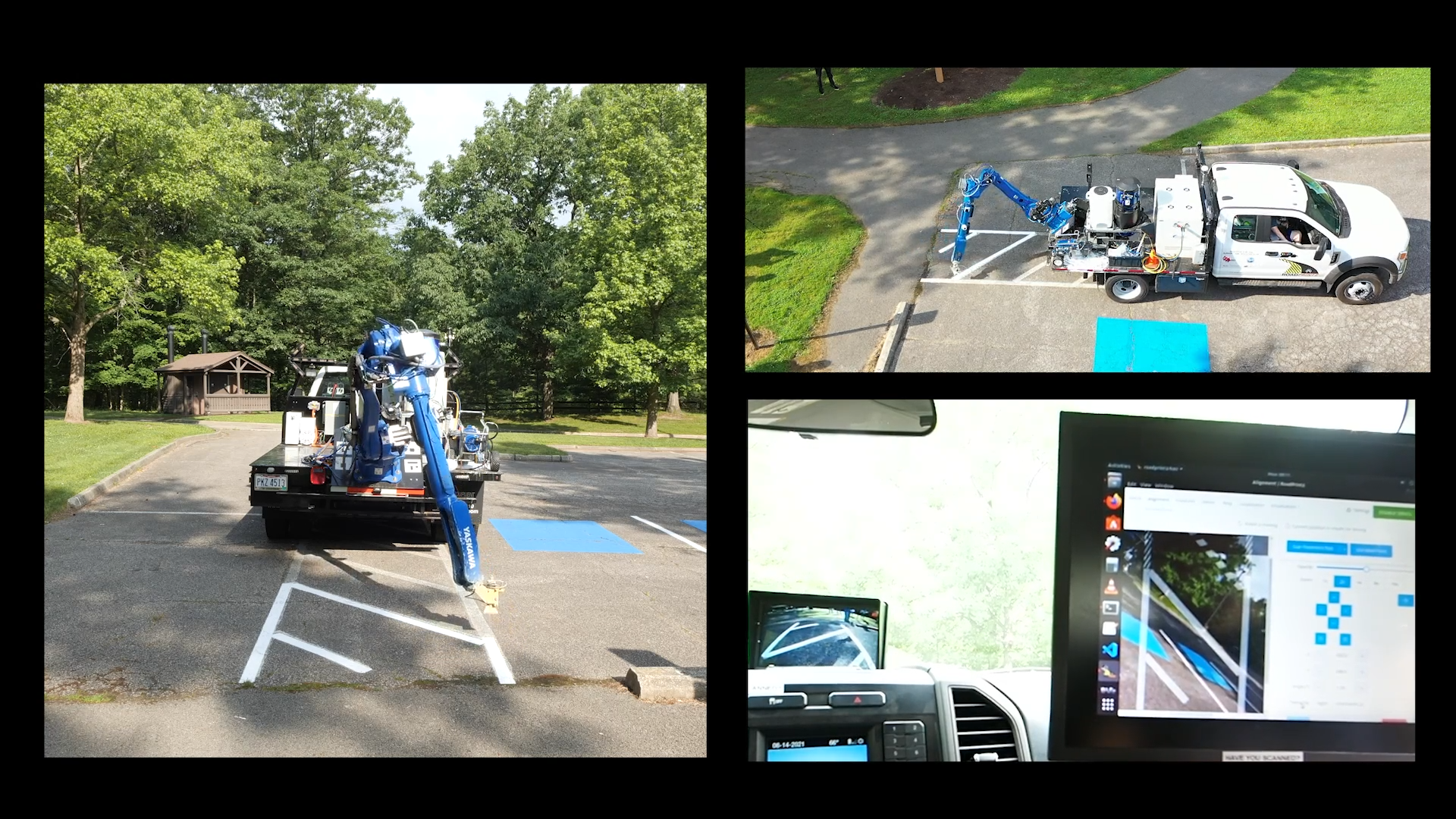

Where automation meets the road

Innovation and engineering combine to create safer roadways

January 25, 2022

Cover story

The factory of the future is now

Smart technology, the Internet of Things and robotics are changing manufacturing operations

November 6, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest safety trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing