With nearly 126 million full-time U.S. workers at risk of occupational illness and injury, it is critical to prioritize our research efforts to address the most important issues. One approach used by the National Institute for Occupational Safety and Health (NIOSH) and its partners to establish priorities is to consider the burden, need, and impact of potential research topics. This method allows us to identify the most important and impactful research to conduct and helps to ensure we are being good stewards of the resources entrusted to us. Another method of maximizing resources to efficiently address the most important safety and health needs is to examine issues relevant to multiple industries, thereby broadening the potential impact.

The construction and mining industries share many similar work processes—such as ground clearing, drilling, blasting, trenching, tunneling, excavating and transporting earth, and vehicular and pedestrian traffic—that can create health and safety hazards. They also share hazards related to use of heavy equipment for earth moving and exposures to contaminants. Because of these similarities, we are evaluating how the mining and construction industries can share and benefit from NIOSH research conducted in each sector.

Beginning in 2017, at the direction of NIOSH construction and mining leadership along with leadership from CPWR-The Center for Construction Research and Training (CPWR), the NIOSH-funded National Construction Center, we began holding periodic meetings and interactions to review our research and products in both sectors and evaluate commonalities in the construction and mining sectors.

Construction comprises residential and commercial building and heavy and civil engineering (e.g., water and sewer lines, highways, and bridges), and includes specialty trades such as roofing, plumbing, electrical, and drywall. About 10 million workers are employed in construction in the U.S., and these workers face risks of fatal and non-fatal injuries resulting from falls from elevated surfaces, struck-by incidents, and musculoskeletal disorders, as well as illnesses from noise, silica, and other exposures. Construction work is demanding and labor-intensive, involving significant manual material handling and awkward postures. Many of the building trades require skilled workers who are sometimes in short supply (CPWR 2018).

The mining industry includes coal mining, metal ore mining, and nonmetallic mineral mining and quarrying. In 2015, the U.S. mining sector employed approximately 349,000 workers. Miners face risks that include falling materials, entanglements with conveyor systems, struck-by incidents, explosions, fires, powered haulage, overexertion and related musculoskeletal disorders, electrical equipment, and exposure to noise and to particulates and dusts including diesel emissions, coal dust, and silica.

Both construction and mining involve dynamic jobsites and hazardous, dusty, and noisy environments with widespread use of heavy equipment such as backhoe loaders, bulldozers, and diesel engines. These sectors also rely on haul trucks and other transportation systems. Emissions resulting from construction and mining activities include many of the same airborne contaminants such as diesel exhaust from large construction equipment; carbon monoxide, nitrogen oxides, and particulate matter from engines; and silica from ground-moving operations. Fugitive dust emissions are caused by disturbing and moving soils, blowing dust from moving vehicles, and other activities (Ringen, Seegal et al. 1995, Donoghue 2004, Saleh and Cummings 2011).

Mineral dusts and the respiratory diseases they cause continue to be substantial problems for both sectors. Dust exposures can cause a spectrum of respiratory diseases and some dusts (e.g., silica, nickel, wood dust) are carcinogens. Hearing problems and musculoskeletal disorders in these industries are also similar. For example, approximately 16.3% of construction workers and 16.7% of miners have some form of hearing impairment (Masterson 2016). Construction workers tend to have higher rates of overexertion injuries compared to miners (CPWR 2018).

Fatality and Injury Data

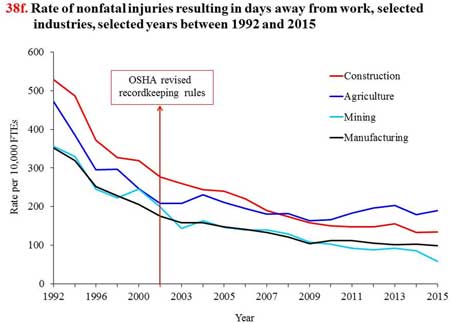

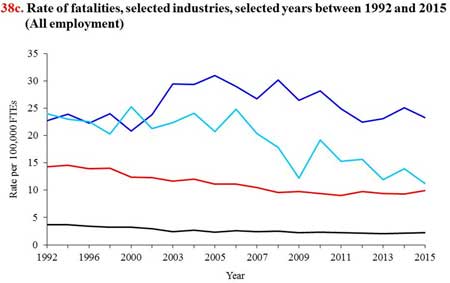

Construction has a higher number of fatalities than mining, but mining has a higher fatality rate. In 2015, workers in the construction sector suffered 985 fatalities from injuries while those in the mining sector had 120 (CPWR 2018). Similarly, the 2015 rate of nonfatal injuries resulting in days away from work was higher in construction (134.8 per 10,000 FTEs) and lower in mining (57.9 per 10,000 FTEs), as shown in Figure 1. A total of 871 fatalities from injuries occurred in mining from 2000 through 2015 (MSHA 2017). By comparison, the rate of mining fatalities was higher than in construction, as shown in Figure 2. However, the difference in the fatality rates had narrowed considerably from 2005 until 2015.

Figure 1. Comparison of nonfatal injury rates in construction, mining, and other industries (CPWR 2018):

Figure 2. Comparison of fatality rates in construction, mining, and other industries (CPWR 2018):

While trends in both fatal and nonfatal injury rates for both industries from 1992 through 2015 are downward (CPWR 2018), the drop in nonfatal injuries appears to be greater than that for fatal injuries in both sectors, suggesting possible under-reporting.

Addressing Three Health and Safety Problems Common to Mining and Construction

Based on the similarities of dusty and noisy work environments using heavy equipment, and common health and safety issues, we have begun to examine how some research activities and outputs apply directly to both sectors. We are also identifying where further work is needed to tailor the products and technologies for workers in both sectors. We have highlighted three areas of possible synergy for the two sectors below.

Reducing Struck-By Incidents Involving Heavy Equipment

Struck-by incidents involving heavy equipment are a significant cause of fatal and nonfatal injuries in both construction and mining. Frequently, these incidents involve vehicles or heavy earth-moving equipment. There has been considerable research in both sectors to identify blind areas for heavy equipment operators. For example, NIOSH worked with Caterpillar Inc.to develop blind area diagrams—drawings depicting areas that cannot be seen from the equipment operator’s position. Research and development on proximity warning devices applicable to both sectors have also moved forward. NIOSH researchers have studied several types of camera systems and sensor devices to address blind spots and reduce struck-by incidents (Schiffbauer 2002, Ruff 2006, Romano, Fosbroke et al. 2008). See the link to the NIOSH Science blog: Construction Equipment Visibility. These tools can be used in both the mining and construction industries.

Reducing Hazardous Exposures to Heavy Equipment Operators

A number of workers in construction and mining operate heavy equipment such as bulldozers and graders, and they are exposed to airborne contaminants, noise, and vibration. Most of the NIOSH research in these areas has addressed airborne contaminant exposures through improved cab designs or retrofits. In order to be effective, these systems should have high-efficiency filters, tight seals on doors and windows, and a pressurized cabin. NIOSH research in this area has been so successful that it is cited in the 2017 OSHA respirable crystalline silica standard for construction. (Hall, Heitbrink et al. 2002, Moyer, Heitbrink et al. 2005, Noll, Cecala et al. 2011), CPWR’s Work Safely with Silica “Create-a-Plan” tool, which OSHA recommends and CPWR Construction Solutions feature the information for cab retrofitting: Cab Filtration Systems for Heavy Equipment. Additional work is needed, however, to more fully address hazardous noise and vibration exposures to equipment operators. CPWR recently conducted a survey of operating engineers to better understand their health and safety concerns. Many of the operating engineers identified silica exposure as an issue, in addition to noise and vibration exposures. They reported that much of the heavy equipment they currently use are not equipped with cab filtration systems. Work to address these needs will be applied to protect both miners and construction workers.

Reducing Exposures to Airborne Contaminants

Video exposure monitoring is an industrial hygiene tool that has existed for many years. This technology links exposure measurement instruments with video and data acquisition systems. This approach to monitoring hazardous exposures can help researchers better understand key exposure sources and develop methods of control (Gressel, Heitbrink et al. 1993). Recently, the NIOSH Mining Program developed the Helmet-CAM technology, which uses a video camera worn by the worker to visually record a worker’s activities concurrently with data collected by a real-time, data logging, personal breathing zone, aerosol monitor (Cecala and O’Brien 2014). See the link to the NIOSH Science blog: The Use of Real-time Respirable Dust Monitors.

As part of the Helmet-CAM technology, the Mining Program also developed the EVADE software (Enhanced Video Analysis of Dust Exposures) to monitor exposure sources. After first being used successfully to monitor dust exposures, EVADE version 2.0 has been expanded to be compatible with instruments that monitor other types of contaminants, such as noise. NIOSH is exploring ways to further utilize this technology to improve worker safety and health in both construction and mining, including through research conducted in collaboration with CPWR’s Masonry r2p Partnership.

Next Steps

In addition to reducing struck-by incidents, hazardous exposures to equipment operators, and exposures to airborne contaminants, NIOSH and CPWR envision that further interactions between mining and construction can maximize resources and ultimately lead to improved safety and health for workers in both industries. Please share with us your ideas for other safety and health topics in common between construction and mining.

References

- Cecala, A. B. and A. D. O’Brien (2014). “Here comes the Helmet-CAM.” Rock Dust, October: 26-30.

- CPWR (2018). The Construction Chart Book—The US construction industry and its workers. Silver Spring, MD, The Center for Construction Research Training-CPWR.

- Donoghue, A. (2004). “Occupational health hazards in mining: an overview.” Occupational medicine 54(5): 283-289.

- Gressel, M. G., W. A. Heitbrink and P. A. Jensen (1993). “Video exposure monitoring—A means of studying sources of occupational air contaminant exposure, Part I—Video exposure monitoring techniques.” Applied Occupational and Environmental Hygiene 8(4): 334-338.

- Hall, R. M., W. A. Heitbrink and L. D. Reed (2002). “Evaluation of a tractor cab using real-time aerosol counting instrumentation.” Applied occupational and environmental hygiene 17(1): 47-54.

- Masterson, E. A. (2016). “Hearing impairment among noise-exposed workers—United States, 2003–2012.” MMWR. Morbidity and mortality weekly report 65.

- Moyer, E. S., W. A. Heitbrink and P. A. Jensen (2005). “Test for the integrity of environmental tractor cab filtration systems.” Journal of occupational and environmental hygiene 2(10): 516-523.

- MSHA (2017). Accident/Injury/Illness: Ground Control Data, 2000-2015. . M. S. a. H. A. U.S. Department of Labor, https://arlweb.msha.gov/fatals/. Arlington, VA: .

- Noll, J., A. Cecala and J. Organiscak (2011). “The effectiveness of several enclosed cab filters and systems for reducing diesel particulate matter.” Society of Mining, Metallurgy and Exploration, Inc., Transactions 2011 328: 408-415.

- Ringen, K., J. Seegal and A. England (1995). “Safety and health in the construction industry.” Annual review of public health 16(1): 165-188.

- Romano, N., D. Fosbroke and T. Ruff (2008). “Improving Work Zone Safety.” Professional Safety 53(4): 46.

- Ruff, T. (2006). “Evaluation of a radar-based proximity warning system for off-highway dump trucks.” Accident Analysis & Prevention 38(1): 92-98.

- Saleh, J. H. and A. M. Cummings (2011). “Safety in the mining industry and the unfinished legacy of mining accidents: safety levers and defense-in-depth for addressing mining hazards.” Safety science 49(6): 764-777.

- Schiffbauer, W. H. (2002). “Active proximity warning system for surface and underground mining applications.” Mining engineering 54(12): 40-48.