FR apparel today is more stylish, functional and performance-driven. Workers transition from work to date night, working out, doing chores around the house in their FR clothing and they want to look good. They also demand performance. There are more moisture wicking options of FR fabrics then there are in the consumer market. The problem is most American workers don’t understand the technology.

What are high performance fabrics?

High performance is a term used to describe moisture wicking technology. These specialized fabrics have been around for more than 20 years. They were created to boost an athlete’s performance in extreme outdoor situations, keeping them drier and cooler in hot conditions and warmer, drier in cold weather. The challenge is understanding the science behind the fabric. The world’s top athlete’s wear high performance fabrics to optimize their performance and have a better concentration on the task in front of them

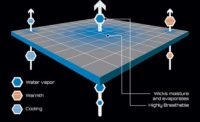

Moisture wicking’s history started with a synthetic fiber (like polyester) with a chemical finish applied to allow moisture to spread. Eventually the finish would wash out and the fabric lost its wicking abilities. The tag on garments will reveal the blend of fibers. A blend of 100% of any fiber along with claims of moisture wicking identifies the presence of a chemical finish. Check to see if the manufacturer guarantees wicking for the life of the garment; chances are they don’t. Today the next generation of high performance fabrics have a combination of hydrophobic (water hating) and hydrophilic (water loving) fibers. Examples of hydrophobic fibers include modacrylic, aramids, para-aramids; hydrophilic fibers include rayon and lyocell. Combining these two fibers blended together ensures permanent moisture wicking for the life of the garment.

The big question then becomes what is the optimal blend of these two fibers that create a soft hand while performing the best?

Finding the balance

Data has proven that the optimal blend is when percentage numbers are closer together, such as a 60 (hydrophobic)/40 (hydrophilic) blend. This allows for better face (skin side) pick up and transport. If you don’t have enough hydrophilic fiber, the fabric won’t absorb well, and if you don’t have enough hydrophobic the fabric will not push the moisture to the front as well. It is the balance of the blend that creates a high performance product.

When choosing a high performance FR fabric based on a numbers alone, ask for the data. It is available. There are different blends of high performance fabrics and they all perform differently. Smart shoppers look at the tags to determine the blend of fabrics and what constitutes high performance. The same high performance fabrics that the world’s top athletes wear is available in the industrial market. There must be a blend of hydrophobic and hydrophilic to have permanent moisture wicking.

These high performance FR fabrics allow garments to be lighter weight and layering -- the next wave of staying better protected. Look for companies that offer a complete layering system that allows for maximum protection, comfort and performance.

Style and fit is the last characteristic for a successful FR program. If a garment looks better and is cut better your workers have the psychological advantage of comfort and safety, knowing their clothes won’t become moisture soaked. Specify the fabric first and then the manufacturer of that fabric. Chances are your FR/AR program will be less expensive and your garments will last longer. Your industrial athletes will be more comfortable, better protected and more focused on the task in front of them.