In the United States, workers required to wear respiratory protection must pass an annual respirator fit test. Fit tests help companies ensure worker safety by verifying a respirator can provide an OSHA-mandated and standardized level of protection.

Real-time measurements of respirator fit

In the past, fit test solutions focused almost exclusively on completing the standardized fit test, as achieving compliance is the goal. Outside of the fit test itself, solutions offered little help with achieving the best possible respirator fit.

A new and welcome trend to the world of respirator fit testing is the increasing usage and prominence of real-time measurements. These dynamic measurements improve staff donning training, speed-up mask selection, provide real-time feedback and pre-verify proper respirator fit.

Real-time measurements not only promote increased safety for workers but also save companies and test administrators a lot of time and effort.

Below we further explore how real time measurements can benefit both safety and efficiency.

A little background

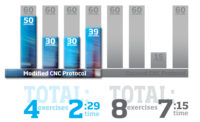

In order to explain how real-time measurements can benefit workers and fit test administrators, we have to discuss first how to obtain them. Real-time measurements of respirator fit are an output of Condensation Nuclei Counter (CNC)-based quantitative fit test instruments. These instruments evaluate fit by measuring air particles both inside and outside a respirator, and then generate live data.

Until recently, real-time or live data was largely unused by fit test administrators due to the importance placed on the final fit test result. Even fit test instruments viewed real-time data as a side feature, as “passing” or “failing” is what mattered most to users.

More recently, instrument providers and program administrators are realizing the benefits of utilizing real-time information during respirator donning and adjustment. These dynamic measurements help to better detail respirator fit and verify protection.

Improving training

The insights provided by real-time measurements may be most impactful by improving respirator training for workers. Fluctuating real-time measurements can show workers exactly how to best don, adjust and wear respirators for optimal levels of respiratory protection.

In addition to improving safety, better training can also save fit test administrators time. Workers provided with a better understanding of how respirators fit, start fit tests properly trained and prepared to pass. They understand how to don, adjust and wear their mask and avoid many of the pitfalls that lead to failed fit tests.

Speeding up mask selection

Real-time data can also be extremely useful for selecting the right size and type of respirator for workers. Mask selection has previously been an inefficient process, mixing trial-and-error and experience to identify masks that will pass a fit test on a worker.

Many long-time mask wearers know what will work for them. However, new employees and those with changing face-shapes due to weight fluctuations and other factors, greatly benefit from a quick real-time measurement.

Beyond the fit test

The fit test is still the “final exam” when it comes to verifying respirator protection, but how you get to a passed test is arguably just as important. Looking beyond the test itself is a positive trend toward finding additional ways to increase safety for respirator wearers and efficiency for respiratory protection programs.

Real-time data allows fit test administrators to achieve safety and efficiency by improving the way workers are prepared for annual fit tests, and by improving the fit test itself.