Electricians, like any trade professional, must complete several training programs to learn the ropes and ultimately earn certification. However, no matter how extensive, their learning is never officially complete. Thanks to advancements in technology, as well as the evolution of industry techniques and standards, professionals must continue their education every few years.

One form of training that must be updated is that of electrical hazards such as shocks and arc flash events. According to OSHA and NFPA 70E, electricians must retrain every three years, at the least.

NFPA 70E1 – 2015 110.2 (D) (3) states that “retraining in safety-related work practices and applicable changes in this standard shall be performed at intervals, not to exceed three years.”

Several reasons may warrant retraining, including:

- If supervisors or inspectors identify an employee who is not in compliance with safety practices;

- When there are changes in technology, equipment or procedures that require familiarization with safety practices;

- When unorthodox or normally unused practices must be applied during regular duties;

- After an accident or event has occurred, including to others, such as colleagues;

- Electrical safety, particularly when it comes to arc flashes,2 is incredibly vital to proper handling and operation, which means every professional should follow through with adequate training.

What does training entail?

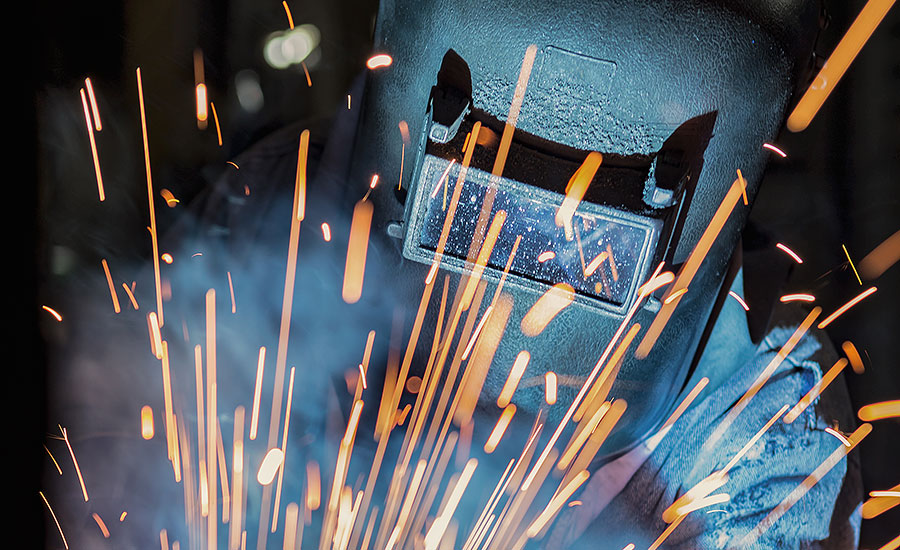

There are a variety of problems and hazards that electricians might encounter during their work. Although fixing and troubleshooting these common problems3 comes with the territory, some instances require more direct experience. An arc flash, for example, is an explosion caused by a buildup in pressure between electrical conductors and a temperature increase. They occur when electrical discharge passes from one voltage source to another, or to the ground.

When an arc flash happens, it can create many dangers like large electrical fires, flying shrapnel, and even pressure waves or shockwaves.

An arc flash can happen for many reasons, including carelessness on the professional’s part, lack of electrical safety and awareness, improper tools or techniques, exposed live parts, static electricity, high-voltage situations and other environmental factors. Dust, debris and corrosion can significantly increase the risk of an arc flash. Someone not properly trained might not be aware of these factors, which means they don't know enough to watch for them or adequately deal with them.

In addition to standard electrical safety and operating techniques, training programs also cover the prevention and handling of various hazards that might occur, including arc flashes.

Because the tools and techniques that electricians use change over time, so do training protocols. Professionals must stay up-to-date with the latest handling and safety methods, not just for their good but also to deliver quality work.

What are the electrical safety objectives?

Every training program — even those for returning or experienced professionals — must cover the appropriate objectives to build total awareness. Some of the most critical touchpoints of an electrical safety training program are:

- The basics of shock hazards, including voltage potentials and possible dangerous events;

- The basics of an arc flash hazard, such as what they are, how to prevent them and how to handle the aftermath;

- Relevant regulations and standards which may differ from employer to employer, such as CSAZ462 for Canada-based operations versus NFPA70E for the United States;

- Employer versus employee responsibilities and when the roles should be updated;

- Electrical job briefing and hazard assessment best practices;

- Personal protective equipment (PPE) training and care;

- Emergency response.

How to select the right training

As with any form of training, there are many places to participate in a program or course. It’s vital that before investing time and money, it's vetted for the appropriate standards. All classes should meet NFPA 70E and OSHA 1910.2694 standards, which have been designed with qualified and active electricians in mind.

The courses may be further specialized depending on the work, such as a track that focuses on power line safety for boom truck drivers, or high-voltage and residential safety for home-based electricians and repair experts.

Choosing a program that matches work is essential and can further awareness and skill, but it’s the alignment with proper standards that makes the difference. NFPA and OSHA have stringent protocols that ensure everyone is using the appropriate security and safety measures.

It’s not an exaggeration to claim that choosing the right training program, especially for arc flash and hazard safety, can be the difference between life and death. Many of the common hazards that electricians encounter are extremely dangerous and will severely damage property, as well as the human body. Arc flash training is critical for safety.

References

- https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=70E

- https://lippoliselectric.com/common-electrical-problems-electrical-troubleshooting/

- https://electricalsafety.lbl.gov/electrical-safety/electrical-safety-program-esp/

- https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.269