No industrial process is completely risk free. New technologies can help reduce risks in the manufacturing process, but many industries still have manufacturing hazards that can badly hurt people and equipment. For example, combustible gases are a risk factor in industries like oil, petrochemical, and mining, but new technologies like combustible gas sensors can alleviate risks associated with these gases. Accurate sensors are essential to monitoring industrial processes to detect deviations from the norm and to properly address any potential dangers.

Most, if not all, modern-day sensors take some physical quantity and convert it into a voltage. A temperature sensor, for instance, contains an electrical element that changes with temperature. A change in temperature is measured as a change in voltage, which in turn is converted to a temperature in degrees. For a single sensor, making a decision can be simple: if it gets too hot, turn the machinery off. But what if that sensor is not perfectly accurate? Most sensors have some amount of uncertainty in their spec sheet. What if, instead of just one sensor, you have hundreds or thousands? Making a simple rule to govern your equipment becomes nearly impossible.

Fuzzy logic - human logic for machines

In the case of a single temperature sensor, shutting off the equipment is simply a binary decision; if the current temperature is greater than a threshold, turn it off. The computer doesn’t really know what “hot” or “cold” is. In recent years, computer scientists have created a type of logic called fuzzy logic that tries to convert qualities into quantities. Figure 1 shows an example for the temperature sensor.

Fuzzy logic enables a machine to make decisions based on qualities a human can understand. A possible rule for a machine with multiple temperature sensors based on fuzzy logic could be: “If two sensors are hot or five sensors are warm, shut off the machine.” Fuzzy logic bridges the gap between a computer, which likes numbers, and a human, who cares about what the numbers mean.

Fuzzy logic, big data, and the cloud

Modern factories have countless, diverse sensors to monitor all steps in the pipeline. Some decisions, like a machine overheating, may be much more critical than others, like an auxiliary component needing replacement. Critical decisions need to be effected as quickly and closely to the equipment as possible, and an overall status needs to be available for supervisors.

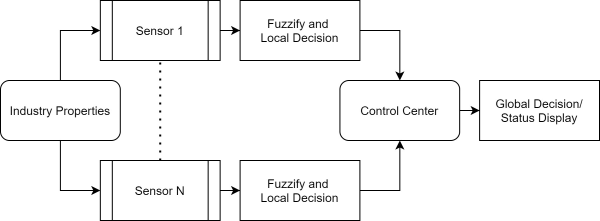

A potential fuzzy logic-based method for aggregating and making decisions on sensor information is shown in Figure 2. The myriad of noisy sensors are shown as “detection methods,” with critical sensors having a direct line to making an urgent decision, like shutting off equipment. The measurements and decisions from all sensors are then combined in the control center, where the more complicated rules reside. The control center accounts for the uncertainty associated with each sensor in the ensemble and makes informed decisions by incorporating knowledge from many sensors simultaneously.

The control center also enables a dashboard with qualitative figures for supervisors. Rather than arduously deciphering a bunch of numbers on a screen, more readily informative statements can be shown like “pipeline 1 is all clear, but pipeline 2 has a slight gas buildup in segment 5 - check for a possible leak.”

The sheer volume and variety of data generated by so many unique sensors easily qualifies as “big data,” which comes with several challenges and benefits. If the data can be properly aggregated, handled, and stored in the cloud, then many doors are opened towards predictive modeling using statistics and machine learning. Dangers can be predicted in advance by learning from patterns in fuzzy sensor data.

Conclusion

As sensors in industrial processes get more advanced, so must the way we process the information from these sensors. By bridging the gap from computer logic to human understanding, fuzzy logic is a huge boon for industrial safety system effectiveness and user confidence.