The inundation of all safety recommendations can be overwhelming and result in even the most basic of mistakes. It’s important to go back to the basics and review the most common ways to reduce electrical risks within facilities.

De-energize all equipment before working on it

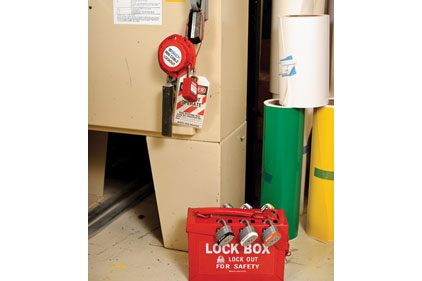

The most surefire way to eliminate electrical hazards is to de-energize equipment before working, testing or repairing systems. Until equipment and systems are placed in an electrically safe working condition, electrical hazards pose an extremely high risk.

It is reported that 80 percent of electrical injuries within the U.S. could have been avoided if equipment was powered down or de-energized and locked out prior to completing any tasks. Some of the most common reasons employees and employers continue to work with energized equipment is to avoid paying overtime, slowing down production time or just because it seems inconvenient and takes too long. Mandate that equipment is de-energized and you reduce the number of electrical liabilities in your facility and put employee safety at top of mind.

Update and test your equipment

In addition to making sure electrical equipment is properly locked and tagged out before use, it is also critical to make sure equipment is up-to-date and safe for use. According to NFPA 70E standard 110.9(A)(1) Use of Equipment, Rating, instruments, equipment and their accessories need to be tested and rated for the circuit to which they will be connected. Make sure all cords have good insulation and proper coding to meet voltage, wire size and conditioning requirements.

Identify your wires correctly

It is critical to be able to quickly identify the wires and cables at your location so essential information is available to employees at the point of need. Proper labeling and schematics make several workplace activities more efficient and effective. Proper electrical system identification can significantly reduce labor costs associated with most maintenance or upgrade projects. With such a variety of wires, labels, sleeves and tags available, it is easy to create legible identification, but it is also easy to inconsistently identify your wires with the incorrect label materials. If you are unsure what type of wires to use, use a third-party organization that specializes in wires. They will be able to outline the myriad of options available for identification solutions based on your application.

Incomplete wiring identification not only wastes time and resources, but opens the door to an electrical hazard and injury. Using poor quality labels can create bigger issues in the future and reduce productivity, performance, safety and security within your facility.

Wear appropriate safety gear

Ensure your employees have the right clothing and PPE to work on potentially hazardous equipment. Some employees forego arc-rated gear because of discomfort. But advances in FR clothing have made it lighter weight and more comfortable. Bottom line: PPE saves lives and prevents injury if an electrical hazard were to occur.

Most individuals who work on common electrical equipment only require clothing that meets category 1 or 2, while NFPA 70E electrical standards are aimed more toward employees who work on more hazardous pieces of equipment and need to wear category 3 or 4 hazard classifications of clothing. Proper safety gear includes gloves, headgear, footwear, eyeglasses, clothing, hearing protection and other tools. It is also critical for employees to be aware of the life-span or expiration date of materials. Eliminate clothing that is worn out or has been damaged.

Use specific arc flash labels

Inform your employees about electrical hazards to keep them out of harm’s way. The best and most effective way to prevent arc flash and other electrical hazards is to display visually instructive labels and signage that communicate hazards and warning messages.

Also, ensure that all of your arc flash labels meet the labeling requirements outlined in the 2012 NFPA 70E. Prior to 2009, it was not specified by NFPA or OSHA that it was necessary to have equipment-specific arc flash labels with detailed hazard information in the facility. When the NFPA updated its standards in 2012, it was modified to require specific elements that needed to appear on the label in reference to the piece of equipment that the label identifies. If you are currently using generic labels, take the time to re-label and re-classify each piece of equipment, not only to comply with NFPA standards, but also to ensure clear and concise communication for your employees.

Be proactive

Employees cannot rely on someone else to ensure their safety. If an employee is unsure if a circuit has been checked or is just unsure how to perform a task, they must be proactive. They should check the circuit or ask an authoritative supervisor. Employees are more likely to prevent injury and accident by relying on their own safety protocols than to put trust in others.

Stay updated on training and education

Failing to train employees on the proper way to work on electrical equipment doesn’t just result in OSHA fines but could result in serious injury. It is very important that all tasks performed throughout the facility are performed by trained personnel using appropriate tools and PPE. Without proper training and guidance, employees may not be aware of protocols and proper handling of an electrical hazard.

While many injuries are caused by human error, you can still work to avoid arc flash and electrical hazard accidents. Complete regular scans and analysis of equipment, work practices and safety training programs. Take the extra steps to reduce equipment failure, loose connections and ensure that you are helping to safe-guard your workers from a hazardous injury.