Home » dust collection

Articles Tagged with ''dust collection''

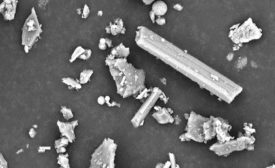

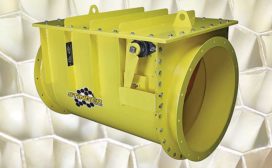

Don't take risks with dust hazards

Only qualified persons should manage dust hazards due to explosion risk and liability

July 15, 2021

2020 Top Standards: NFPA

NFPA 652 standard on fundamentals of combustible dust

December 20, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest safety trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing