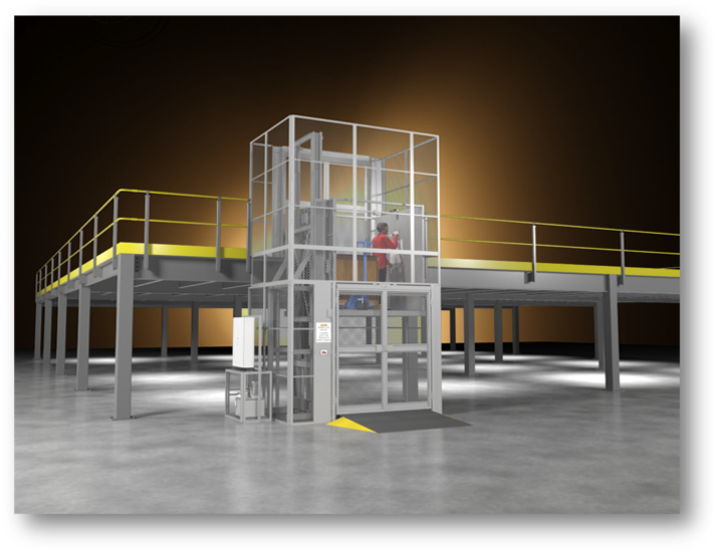

Wildeck, Inc. – Material handling equipment and safety products manufacturer, Wildeck, Inc., has introduced a new product category for vertical material lifts. The new “RML” product category is a major advancement over a traditional “VRC” (vertical reciprocating conveyor) since it allows authorized personnel to safely travel with their material between levels. Wildeck will introduce its new “RiderLift™” hydraulically-operated rideable material lift (RML) in Wildeck Booth # S-1012 at ProMat 2017, April 3-6, McCormick Place, Chicago, IL.

Wildeck, Inc. – Material handling equipment and safety products manufacturer, Wildeck, Inc., has introduced a new product category for vertical material lifts. The new “RML” product category is a major advancement over a traditional “VRC” (vertical reciprocating conveyor) since it allows authorized personnel to safely travel with their material between levels. Wildeck will introduce its new “RiderLift™” hydraulically-operated rideable material lift (RML) in Wildeck Booth # S-1012 at ProMat 2017, April 3-6, McCormick Place, Chicago, IL.

“Wildeck’s new RiderLift™ Type B Rideable Material Lift (RML) is a breakthrough new product and is in a class by itself,” stated Hubert Schlegel – Director of Marketing for Wildeck. “Customers can now enjoy the convenience of an elevator at a fraction of the cost. The RiderLift™ RML is ideally suited for industrial applications and, unlike a VRC (vertical reciprocating conveyor), the RiderLift™ has been designed to allow an authorized person to ride with their cargo to a second level and avoid having to climb stairs or rely on a co-worker to off-load material when the lift reaches its destination. Now who wouldn’t enjoy that?!”

Benefits of Wildeck’s new RML (rideable material lift):

- Increases material handling efficiency

- Saves time by allowing workers to travel between levels with their material

- Improves safety, reduces fatigue, and minimizes lost time accidents

- Increases the utilization of facility capacity gained from mezzanines, rack systems, and pick modules

- Can be purchased and installed at a fraction of the cost of an elevator

“We are extremely excited about the numerous potential applications for our new RiderLift™”, states Schlegel. “The ability to ride between mezzanine levels with their material has been requested by many customers and Wildeck is proud to be the first major lift manufacturer to offer such an elegant and affordable solution.”

Standard car size is 6.0 ft. x 6.0 ft. x 80” H, and lifting capacity is 2,500 lbs., including rider. Standard top lifting height is 14 ft. (GND + 1) and lifting speed is 20 fpm. The RiderLift™ material lift is available in either “C” or “Z” loading patterns and features a keyed “enable” switch inside the car to ensure use only by authorized personnel. The RiderLift™ RML meets ASME A17.1 / CSA B44 code requirements. Qualified Elevator Contractors will install and service the lift and provide the end user with ongoing State-approved safety inspections and lift Certification, as required by the A17.1 code.

A service, parts, and technical support Help-Line is available 24-7 at 800-325-6939 to keep the RiderLift™ RML and any other Wildeck® vertical lift operating at peak efficiency. According to Todd Canham, Product Manager, Lift Products, “The RiderLift™ material lift is part of Wildeck’s continuing commitment to helping our customers’ projects run smoothly while making their operations safer, more efficient, and more profitable.”

Wildeck, Inc. – based in Waukesha, WI – is a member of MHI (Material Handling Industry Association), MHEDA (Material Handling Equipment Distributors Association), and the NAEC (National Association of Elevator Contractors). The company is the largest manufacturer of manual and automated vertical lifts (VRCs), rideable material lifts (RMLs), structural steel mezzanine platforms, and safety guarding products in North America. A complete line of industrial rolling ladders, custom-designed work platforms and other high access products are also available. Wildeck products improve supply chain productivity and provide additional capacity, efficiency and safety in manufacturing plants, warehouses, distribution centers, and many other facilities. They are sold through a dedicated and experienced network of customer-service-oriented dealers and systems integrators nationwide.

Wildeck, Inc. is a subsidiary of Holden Industries, a 100% Employee-Owned Company. Please contact Hue Schlegel, Director of Marketing at 262-549-4000, ext. 2049, hschlegel@wildeck.com for more information on the complete line of Wildeck® and Ladder Industries products and services; or visit www.wildeck.com or www.ladderindustries.com, or e-mail info@wildeck.com.