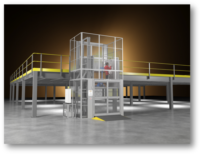

Material handling equipment and safety products manufacturer, Wildeck, Inc., has introduced a new LiftLok™ VRC safety system to prevent lift operation by untrained or unauthorized personnel. A basic key switch or a more feature rich 10-key pushbutton digital keypad can be added to any Wildeck mechanical or hydraulically-operated VRC (Vertical Reciprocating Conveyor). Two keys are provided with the basic LiftLok™ keyed system while authorized lift operators can enter a unique 4-digit user/passcode, or swipe their pre-programmed proximity credentials tag (key fob) on the LiftLok™ digital keypad to enable lift operation.

According to Hubert Schlegel, Director of Marketing at Wildeck, “Safety remains a top concern in manufacturing facilities, warehouses, and distribution centers nationwide and Wildeck is pleased to offer this easy-to-use VRC operator control device. The affordable LiftLok™ key switch or LiftLok™ keypad system will ensure that only properly trained personnel can operate a material lift in their facility. Besides main floor call/send control box installation, the LiftLok™ safety device can be included with call/send VRC control stations at every level.”

To simplify VRC installation with the feature-rich LiftLok™ keypad system, two administrative level programming codes are included for use by the installer. Once installed, authorized lift operators can be assigned a secure 4-digit user passcode to activate the call/send control station and operate the lift. Although access to the lift is typically assigned to only a few authorized personnel, up to 500 user passcodes can be programmed into the LiftLok™ keypad system. This ensures maximum user flexibility and long service life, since old user passcodes can be retired/deactivated and new codes assigned as responsibilities or personnel change.

- LiftLok™ system keeps unauthorized personnel from operating the VRC

- 10-Digit Keypad System or Key Switch available

- Administrative level programming codes simplify installation

- Up to 500 user passcodes available for maximum operator assignment flexibility

- Proximity Credentials Tag (Key Fob) speeds access for authorized personnel

- Weather-resistant control cabinet for outdoor VRC installations

Wildeck’s innovative LiftLok™ VRC safety system will be shown for the first time in Booth # S-1012 at ProMat 2017, April 3-6, McCormick Place, Chicago, IL.

Wildeck, Inc. – based in Waukesha, WI – is a member of MHI (Material Handling Industry Association), MHEDA (Material Handling Equipment Distributors Association), the FMA (Fabricators & Manufacturers Association, International), and the NAEC (National Association of Elevator Contractors). The company is the largest manufacturer of safety guarding products, structural steel mezzanine platforms, manual and automated vertical lifts (VRCs), and rideable material lifts (RMLs) in North America. A complete line of industrial rolling ladders, custom-designed work platforms and other high access products are also available. Wildeck products improve supply chain productivity and provide additional capacity, efficiency and safety in manufacturing plants, warehouses, distribution centers, and many other facilities. They are sold through a dedicated and experienced network of customer-service-oriented dealers and systems integrators nationwide.

Wildeck, Inc. is a subsidiary of Holden Industries, a 100% Employee-Owned Company. Please contact Hue Schlegel, Director of Marketing at 262-549-4000, ext. 2049, hschlegel@wildeck.com for more information on the complete line of Wildeck® and Ladder Industries products and services; or visit www.wildeck.com or www.ladderindustries.com, or e-mail info@wildeck.com.