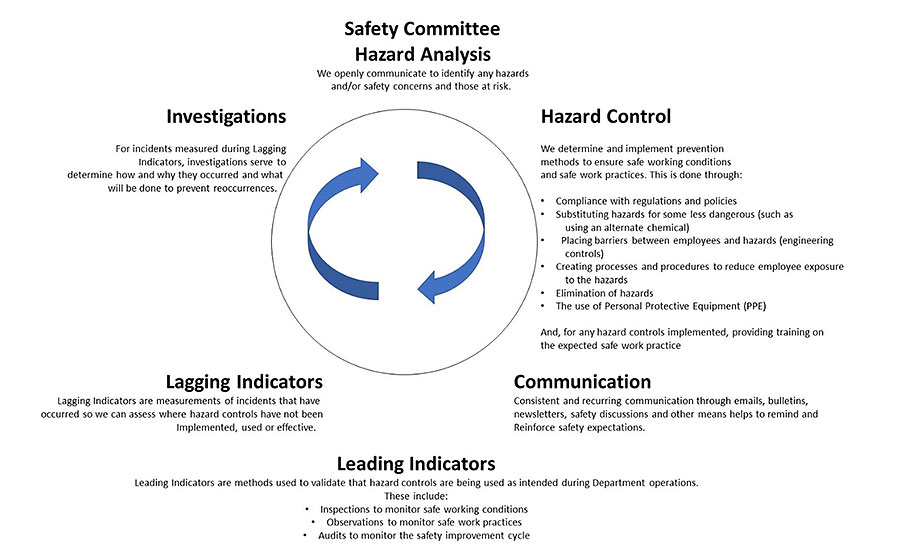

In parts one and two of this three-part series, COVID-19’s hazard analysis, risk assessment and hazard controls were covered within the risk management construct. However, these functions only cover the first, planning half of the continual improvement cycle. Once hazard controls are implemented, communication, indicators and investigations are needed to ensure continual improvement in incident prevention.

Communication

With the hazard analyzed, risk assessed, and controls implemented, these controls and expectations must now be communicated to all affected. For example, if employees are expected to stay at home, if employees are expected to maintain social distancing or if employees are expected to provide services within 6 feet of potentially infectious persons, these expectations must be communicated. Further, each employee requires training as necessary on how to perform the expectation (such as using PPE or maintaining social distancing).

See the additional articles in this series, and more from Cory Worden, M.S., CSHM

In some schools of thought, teams are asked to communicate expectations and information 100 times while others are asked to communicate seven different ways, seven times each. In any case, it’s important that communication be frequent and consistent, so the message is clear.

Leading indicators

With the hazard analyzed, risk assessed, controls implemented and communication taking place, leading indicators are the means to validate if the safety expectations are being met before an incident occurs. Leading indicators can be accomplished in several ways:

- Observations to validate safe work practices / safe behaviors

- Inspection to validate safe work conditions

- Surveys to validate perceptions of safety among employees, citizens or another group

- Near-miss reports to check for possible/probable incidents in the future

- Recognition/Incentive programs to provide positive reinforcement

- And more

For example, if the expectation is to maintain social distancing, this can be done with observations to see if employees are maintaining at least 6 feet from one another. Also, inspections can be done to see if facilities are set up accordingly so that 6-foot distances are possible. Surveys can be done to see if employee perceptions are such that they feel supervisors care taking the virus seriously and monitoring for safety.

Near-miss reports can be promoted to know if situations exist in which employees are within 6 feet of each other and risking exposures. Recognition and incentive programs can be implemented to recognize those helping with observations, inspections and near-miss reports and to recognize those actively maintaining social distancing. Ultimately, leading indicators provide information on whether the team is heading for safety or for incidents through promoting participation, engagement and safe work practices and conditions.

Lagging indicators

Lagging indicators are reports of what’s gone wrong. These could be incident reports, workers compensation claims, financial reports or other means to project events where safety hasn’t happened as it should have. In the case of COVID 19, this could mean exposure reports, medical reports for confirmed cases, Americans with Disabilities Act (ADA) accommodations and more.

It’s also important to note that all these lagging indicators are subject to the Healthcare Insurance Portability and Accountability Act (HIPAA), especially when employee illnesses are concerned. With COVID 19, this is a very important factor; employees with COVID 19 cannot be called out to others, even when their areas require disinfection. These issues require handling with tact and care. Ultimately, lagging indicators are very important because they provide insight into where the existing safety protocols didn’t work as intended.

Investigations and preventative measures

The last step of the safety analysis cycle is the investigation of the lagging indicators and preventative measures. Now that we know the lagging indicators and know where the existing safety protocols weren’t as effective as necessary, we can investigate to determine where the gaps were and how to prevent them in the future.

For example, with COVID 19, were employees working among each other where they could have been working remotely? Were employees working among citizens where there could have been barriers or social distancing? Were employees providing services within 6 feet without proper respirators and PPE? Each of the hazard controls and their preceding risk assessment can be reviewed to determine if and where preventative measures are possible and feasible. From there, continual improvement is possible to prevent exposures.

In summary

Ultimately, to protect against COVID-19 and to minimize possibilities for exposures, each organization must determine its acceptable level of risk and the controls necessary for that level of risk. To implement these controls, many are implemented simultaneously for each applicable work area. While some can quarantine and work remotely, others are able to maintain separate work spaces.

Meanwhile, others work together but maintain social distancing, disinfecting procedures, hand hygiene, temperature checks and other administrative controls. Between these, they minimize the number of employees not in quarantine, minimize possibilities for exposures and then provide redundant disinfecting and distancing as an added control. Then, while all these protocols are being followed, others needing to provide services to already-known-to-be infectious persons have PPE and the proper preparedness to do so and avoid cross-contamination.

With these controls implemented, we can then communicate these expectations and validate them through leading indicators. If any controls aren’t as effective as necessary, lagging indicators will then provide that information (if not already identified through leading indicators) and investigations provide insight into how and why the incident occurred and what preventative measures can be implemented to prevent reoccurrences. Through this ongoing cycle, the safest possible work can continue.

References

1. The Institutes. (n.d.). Holistically assessing risk. The Institutes: Malvern, PA.

2. Worden, C. (2014). Safety diligence. Organization Impact Safety Solutions: Houston, TX.

3. Worden, C. (2015). Situational safety. Organizational Impact Safety Solutions: Houston, TX.