Many workers consider cracked or dry skin simply part of the job. But cracked skin, especially, can be cause for serious concern if harmful substances are able to more easily penetrate the skin’s compromised outer layer. Proactively addressing this critical aspect of workplace safety can reduce injuries and lost work time while contributing to a healthier, more productive workforce.

Proper skin care can actually impact your business’s bottom line, as the following “Countdown to Savings” will illustrate.

“3” – Provide a three-step skin care program

One effective way to help prevent skin irritation is to institute a three-step skin care program that begins with the application of an effective before-work cream, continues with the application of a skin-compatible cleanser, and concludes with the application of an after-work moisturizing cream, all products specific to the substances being handled.

Before Work: In many situations, gloves are not an option — e.g., due to the risk of getting caught in machinery or because they do not allow sufficient dexterity. Here, a before-work cream should be used to help maintain the integrity of the outer skin layer.

As with all personal protection equipment, base cream selection should be based on an appropriate hazard assessment, taking into account the nature of the work environment. All-purpose creams usually do not help. A hazard-specific product, backed by efficacy studies, is the key to starting your skin care program off right. Once identified, the appropriate before-work creams should be dispensed from a location that can be easily accessed. Small, portable, sample-size “squeeze tubes” tend to get misplaced. A wall-mounted dispenser near the wash-up area or locker room is preferable, as it allows more visible compliance.

Hand Cleanser: The second step is to select the most appropriate type of hand cleanser. Avoid common cleaners such as paint thinner, abrasive powders, and solvent or d’limonene-based hand cleaners, so called “orange” hand soaps. According to the NIOSH Current Intelligence Bulletin 48 on Organic Solvent Neurotoxicity, certain chemicals found in common paint thinner, such as xylene, can be absorbed into the bloodstream within 15 minutes of contact with skin.2

Borax- and pumice-based abrasive hand cleaners strip away the skin’s natural barrier — the stratum corneum — increasing susceptibility to rashes and dermatitis. Petroleum-based solvents may cause a defatting action on the skin, while hand cleaners that contain orange d’limonene solvent may cause allergic reactions and dry skin.

Other potential contributors to dry skin conditions and dermatological issues include: cleaning hands with a product that is too aggressive for the hazard being removed, washing hands too frequently or with hot water (tepid is best), inadequately rinsing off the cleaning product, and using products containing pumice-based scrubbing agents.

After Work: Frequent skin contact with hazardous substances requires an effective after-work cream that helps the skin heal and regenerate. Most people are familiar with the benefits of using a good skin moisturizer to replace lost moisture and skin lipids, especially during winter months when the combination of lower outdoor humidity and heated indoor air results in additional moisture loss.

As warm air is capable of holding more moisture than cold air, heated indoor air acts like a sponge, absorbing moisture from everything it touches, including human skin. In these conditions, the use of a harsh hand cleaner can severely aggravate skin irritation, and frequent use of even the most skin-friendly hand cleaner can leave the skin dry. Choose a moisturizing and conditioning product formulated for workplace conditions. Most conditioning products sold at retail stores contain about 90% water. A product containing 15% to 30% lipids (fat derivatives), depending on the degree of skin dryness, is preferable for working skin.

“2” – Implement two key initiatives

The success of your “Countdown to Savings” strategy hinges upon the implementation of two key initiatives: Education and product availability.

Education: To prevent skin damage, it is vital to educate workers about the importance of maintaining healthy skin and to advise them that proper skin care can prevent physician visits and lost work time. Workers should know about the potential hazards of the substances they work with and how those substances can affect their skin. Education on the safe and effective removal of potentially harmful substances from the hands, both during and after the workday, is also important. Training posters, pamphlets, and videos offer excellent support for your efforts to educate employees on the proper use of before-work skin creams.

Need a new safety meeting topic? Search no further. Offer them a topic they can all relate to: Skin Health.

Product Availability: In this current economic environment, where all companies are tightening their belts and cutting costs wherever possible, purchasing agents and other personnel looking at budgetary entries may scrutinize employee health and safety programs. Cutting one or more skin care products will increase worker exposure to skin hazards and elevate the chances of developing occupational dermatitis. To satisfy the most budget-critical financial analyst, examine the costs associated with occupational dermatitis and the potential savings that can be gained by preventing it.

“1” – Cost savings

Employers who do not consider the possibility that dermatitis may occur at their workplace could be making a very costly mistake. Results provided in a recent study published in theArchives of Dermatologyof the American Medical Association clearly demonstrate the significant financial impact to business that occupational dermatitis claims represent.3

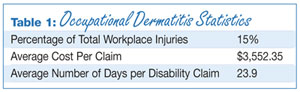

Table 1 (below) presents three key results of the study. For starters, dermatitis on the job was found to account for nearly 15% of total workplace injuries, putting it among the most prevalent of occupational disorders. In addition, the mean cost-per-dermatitis claim — including total temporary disability, medical treatment, partial permanent disability, and vocational rehabilitation — was found to be $3,552.35. Equally impacting a company’s productivity was the documented average disability time: 23.9 days.

How profitable would your business be if a vital piece of machinery were unavailable for nearly a month? Bottom line: Proactive prevention could save your company a lot of money.

References

1. http://www.cdc.gov/niosh/topics/skin/skinresearch.html. NORA Dermal Exposure Research program (DERP).2. http:// www.cdc.gov/niosh/87104_48.html DHHS (NIOSH) Publication No. 87-104; CURRENT INTELLIGENT BULLETIN 48-ORGANIC SOLVENT NEUROTOXICITY; March 31, 1987.

3. http://archderm.ama-assn.org/cgi/content/full/141/6/713Archives of Dermatology, Vol 141, June 2005, “Incidence Rates, Costs, Severity, and Work-Related Factors of Occupational Dermatitis,” Brian P. McCall, PhD; Irwin B. Horwitz, PhD; Steve R. Feldman, MD, PhD; Rajesh Balkrishnan, PhD., p. 715.