You might be surprised to learn that many of the same technologies used to construct “Watson,” the supercomputer that beat the best human champions on the game show “Jeopardy,” as well as the “Deep Blue” supercomputer that defeated Gary Kasparov and other chess masters, are being employed to bring cutting edge predictive and advanced analytics to the field of safety.

Safety experts along with artificial intelligence experts from the School of Computer Science at Carnegie Mellon University (the team that helped build Watson and Deep Blue), have been analyzing workplace safety data and building predictive and advanced analytics models based on these methodologies. The models have proven to be very effective with accuracy rates of 85 percent and, for those of you statistically inclined, R2 correlation measures of 0.75.

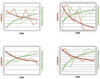

Companies employing these analytics techniques to prevent workplace injuries and safety incidents see dramatic results. The graphics to the right are examples of actual companies who reduced their incident rates (red line) through increased safety data collection and use of advanced analytics (green line).

What is predictive analytics?

Predictive analytics is the practice of collecting raw data (often in very large quantities), and turning that data into actionable information. Based on this information, inferences about future outcomes, or predictions, can be made. By predicting workplace injuries, they can be prevented from ever happening.This is exactly what the companies represented in Figure I have accomplished. Through the use of advanced and predictive analytics, they prevented significant numbers of workplace injuries and attained best-in-class safety results.

Demystifying predictive analytics

When the raw data being analyzed is relatively small and one has sufficient past experience to rely on, the human brain is a fantastic analytics tool. But as data sets grow larger, or go beyond our experience, the human brain has its limitations. This is when we turn to computers that employ artificial intelligence techniques to sift through large data sets and address complex problems that are beyond the limitations of the human brain.

Figure II: The Power of Advanced and Predictive Analytics

The need for machine-based advanced and predictive analytics in safety

Figure 66 takes this machine-based analytics discussion and relates it to the function of safety. It shows a framework adapted from the book, “Competing on Analytics” by Thomas Davenport and Jeanne Harris. For most companies, basic analytics, oftentimes executed by humans on simple spreadsheets or in standard databases, are simply not powerful enough to achieve appropriate levels of incident prevention. Advanced analytics, performed by machines or computers running very powerful applications, are needed to sift through extremely large safety data sets and answer complex safety questions such as, “Across my numerous worksites, where will my next incident occur?”The most powerful of this set of advanced analytics is predictive modeling, represented by the green area in the graphic below. Several predictive models focused on safety have been developed by leveraging an immense data store of real-world workplace safety data including 100 million safety observations taken from two million safety inspections conducted across more than 15,000 worksites.

How are computers used to help with predictions?

Broadly, there are two ways computers can help with predictions. First, the large data processing capabilities can be exploited to help identify well-known warning signs. Safety professionals are aware of these signs but cannot observe them because they are overwhelmed by the sheer size of the data they are analyzing. The benefit of using the computational tools is the ability to perform the task tirelessly, repeatedly and without error across very large data sets. The results can be suitably summarized in reports created for a safety professional to act upon.A second way is to use the computer to identify new hitherto unknown warning signs or patterns by sifting through large data sets and validating those patterns with historical outcomes. This is not only valuable as a predictive tool, but it is also a great learning tool to help us better understand human behavior and safety.

When used in combination with a skilled professional who can bring their past experiences to bear on the data analysis, both techniques can be powerful tools in managing safety.

Using predictive models in safety

A practical use of predictive models might occur as follows. The vice president of environment, health and safety at a Fortune 1000 company exposes her safety data from her 43 worksites to a predictive model. This model then “red flags” five of those worksites because they fit the profile, based on their safety data, of other worksites that had high levels of safety incidents. The VP then drills further into the data collected from these specific worksites and gets detailed information as to why those five specific worksites were flagged.She might find that though safety inspections occur daily, her team records few to no unsafe or at-risk safety observations. Generally, this is due to inadequate training and as a result, people don’t know what to look for. But other times, it can be a symptom of a weak safety culture where people fear reporting unsafe or at-risk observations for fear of management repercussions. Either way, these situations are not good and represent key leading indicators of risk.

Alternatively, she might find that her team is well-trained and adept at identifying safety risks, and management promotes the reporting of the same. But when it comes time to allocate resources to fix those unsafe or at-risk observations, other priorities such as profitability or production deadlines take precedence and these at-risk occurrences continue to pile up. This is another key leading indicator of risk.

Armed with this information, the VP of EHS can leverage her past experience and knowledge of her specific organization to put in place specific countermeasures to address the at-risk trends that she has uncovered. Rather than focus her time blindly across all 43 worksites, she can focus her scarce resources on those worksites that have high-risk profiles.