|

| Figure 1 |

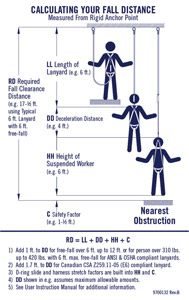

What is fall clearance?

Should a fall occur, there must be a sufficient clearance below the worker to arrest the fall before he or she strikes either the ground or any other object. Workers must determine if the fall protection system will arrest the fall within the available clearance. To do so, certain things need to be taken into account (see Figure 1).

A variety of factors affect fall clearance, none of which should be left out of the equation. Before you start working, make sure you have accurately accounted for each of the following components:

- Anchorage location. Is the anchorage point directly above the point where a fall would occur? If not, this could result in a swing fall, which lengthens the total vertical fall distance. Read more on swing falls below.

- Connecting system. Both the type and the length of your connecting system affect the calculation of the fall clearance (i.e. lanyards, self-retracting lifelines, rope grab). For example, shock-absorbing lanyards typically require more fall clearance than self-retracting lifelines. Know what you’re working with to get the most accurate calculation.

- Deceleration distance. This is the elongation of the decelerating device when deployed. All fall arrest rated deceleration devices, including rope grabs, lanyards and SRLs, are designed to limit the forces exerted on the worker during a fall. A lanyard will have a maximum deceleration distance ranging from 3.5 feet up to 5 feet based on the type and design.

- Height of suspended worker. This distance will typically include D-ring slide and harness stretch. Most often 6 ft. is used to represent the height of a suspended worker.

- Safety factor. Typically a distance of 1.5 feet is used as a margin of safety.

-

Nearest obstruction. This is any object the worker could potentially hit in the event of a fall, including the ground. Know where the nearest obstruction is located, and allow a two-foot safety factor to accommodate for potential D-ring movement and system materials stretch.

Figure 2

It cannot be stressed enough: all of these components must be taken into consideration to have an accurate and safe fall clearance. If you know what the required clearance distance is and you allow for it, you help minimize the chances of hitting an obstruction in the event of a fall. But if you do not know what the required clearance is and/or you miscalculate, the results of a fall can be much worse, even fatal.

Accounting for swing fall hazards

Swing falls occur when the anchorage point is not directly above the point where a fall occurs. The force of striking an object while swinging, which is the horizontal speed of the worker due to the pendulum effect, may cause serious injury. Working as close to directly below the anchorage point as possible can minimize swing falls.

The total vertical fall distance will be greater in a swing fall than if the worker had fallen directly below the anchorage point. Therefore, fall clearance calculations will differ slightly with swing fall hazards. Workers must increase the total free fall distance and account for the distance the worker can move horizontally during the fall (see Figure 2).

SRLs typically provide greater horizontal and vertical mobility than lanyards, increasing the opportunity for swing falls. If you are using an SRL as your connecting system, pay close attention to potential swing fall hazards and determine the necessary clearance distances.