This article will discuss one such deceleration device, the “SRD.” What is it? How should it be used properly and safely? What are its advantages? Are there disadvantages?

OSHA defines a “retractable” as a deceleration device containing a drum-wound line that can be slowly extracted from, or retracted onto, the drum under slight tension during normal employee movement, and which, after onset of a fall, automatically locks the drum and arrests the fall. Once activated, it will stop the action of a fall.

The latest ANSI standard relating to this device is ANSI Z359.14-2012, “safety requirements for self-retracting devices”. This standard supersedes the requirements found in ANSI Z359.1 and Z359.4.

Major points & changes of the new standard

1. Scope, Purpose, Application, Exceptions and Interpretations

1.1 Scope. This standard specifies requirements for qualification and verification testing of ANSI/ASSE Z359, Fall Protection Code, products. It includes requirements for third-party testing, witness testing and manufacturer testing of fall protection products to the requirements of the ANSI/ASSE Z359 standards.

1.2 New Terms: SRD, SRL-R, SRL-LE

SRD – Self-Retracting Devices, includes SRL’s, SRL-R’s and SRL-LE’s

SRL – Self-Retracting Lanyard (or Self-Retracting Lifeline)

SRL-R – SRL with integral rescue capabilities

SRL-LE with leading edge capability.

1.3 Self-Retracting Device Classifications. Self-retracting devices shall be classified according to dynamic performance as follows:

Class A: Maximum arrest distance of 24 inches (610mm).

Class B: Maximum arrest distance of 54 inches (1,372mm).

In addition to a maximum arrest distance of 24 inches, Class A must have an average arresting force not to exceed 1,350 lbs.

Class B must have an average arresting force not to exceed 900 lbs.

Visual indicator

• SRD’s shall include a visual fall indicator. Typically this is built into the snap hook or area near the snap hook. The fall indicator helps provide a positive indication of a fall. External energy absorbers may also be utilized as visual indicators.

Leading edge

• For the first time, a leading edge test for SRD’s is included in the standard. Specific test criteria must be met in order for devices to be labeled for leading edge work (where the lifeline can come in contact with a sharp edge during fall arrest). Devices meeting these requirements are designated SRL-LE. Leading edge rated devices will have specific information both on the label and in the instruction manual provided by the manufacturer. It is interesting to note that for the dynamic testing of SRL-LE devices, the material used for the edge test shall be 3/8 x 3 inch or larger size 1018 cold finished steel bar in accordance with ASTM.A108. See paragraph 4.1.10 in The Standard.

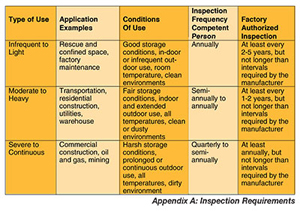

Inspection

New inspection requirements are included. The frequency of inspection by a competent person, and factory authorized inspections, is determined by usage.

As the user, you must conduct an 8-point inspection of your SRD before each use.

1.) Ensure the safety retractable locks when the lifeline is pulled sharply, with no slippage. Lock-up should be positive.

2.) Labels must be present and fully legible.

3.) Check the connecting hooks or carabiners for damage, distortion or corrosion, and working condition.

4.) Check the housing for distortion, cracks or other damage and make sure anchorage point is not distorted or damaged.

5.) Inspect each component of the personal fall protection system according to the manufacturer’s instructions.

6.) The lifeline must fully extend and retract smoothly with no hesitation or slack on the line.

7.) Check the lifeline for cuts, burns, chemical damage, abrasions, loose strands or corrosion; the lifeline must not be damaged.

8.) Check for loose or missing screws and bent or damaged parts.

After a fall, equipment which has been subjected to fall arrest forces MUST be removed from service for inspection. Inspect the entire safety retractable lanyard such as the load/impact indicator. On web style, find the fold on the web to see if the stitching is broken and the fold torn apart, or for wire style, check the swivel snap hook to see if the RED indicator was engaged. The safety retractable lanyard must be removed from service and returned to an authorized service station for repair; do not re-stitch or repair.

Testing and labeling

All required tests must be performed in accordance with The Standard and by a Laboratory which satisfies the requirements of The Standard.

Although self-testing is acceptable providing the above conditions are met, true third-party testing is desirable. Manufacturers may not claim compliance with portions or segments of the requirements. Products should be labeled as being compliant with The Standard.

Self-retracting devices shall be marked to identify:

• Part number and model designation;

• year of manufacture;

• manufacturer’s name or logo;

• capacity range;

• unique ID number;

• standard number (Z359.14);

• how to inspect visual indicator;

• warning to follow the manufacturer’s instructions included with the equipment at time of shipment from the manufacturer;

• warning of the need for inspection in accordance with the manufacturer’s instructions;

• the fiber or other materials used in the lanyard construction;

• the lanyard working length;

• average arresting force for the SRD class;

• arrest distance;

• proper installation means;

• warning of the need for testing of the device for locking and retraction before each use;

• SRD class;

• warning of the need to avoid lanyard contact with sharp edges and abrasive surfaces (not required for leading edge type SRDs);

• free fall limit;

• suitability for use with horizontal lifelines;

• suitability for horizontal use.

“SRL-LE” when?

Which SRD is needed for your application?

Class “A” SRDs should be used only when the tie-off is overhead, the free fall is limited to 24 inches, and there is no possibility of falling over a leading edge. In reality, this is very few situations.

Class “B” SRL-LE should be used for all other applications. The “LE” has a freefall of 54 inches

and is approved for tie-off overhead or at foot level, horizontal installation and of course falls over

leading edges.

Why SRD-LE?

Roofers normally tie-off at the peak of the roof and have a fall hazard that will involve a foot level drop over a sharp edge. Not all equipment is approved for this application. However, the instructions for the product purchased often end up unread on the ground.

For example, I had a large customer who has a huge facility that was built in the ’50s. It required a lot of roof repair, and they hired some high quality sub-contractors to do the work for them. A worker was in the situation where he was on a corrugated roof that gave way. He was in a harness hooked to a retractable. However, as he fell through the roof, he cut the cable on the retractable, fell through the structure to the floor and was seriously injured. This being a large corporation with their own legal team, they went into action against the manufacturer. The manufacturer said, “Did you read our instructions?” Not being familiar with fall protection, the attorneys asked why. After receiving a copy of the instructions, they were shocked to find out the unit was not designed for foot level drops or sharp edges. The wrong equipment had been selected.